7

STV75 ed 01/08 VICTRIX 75

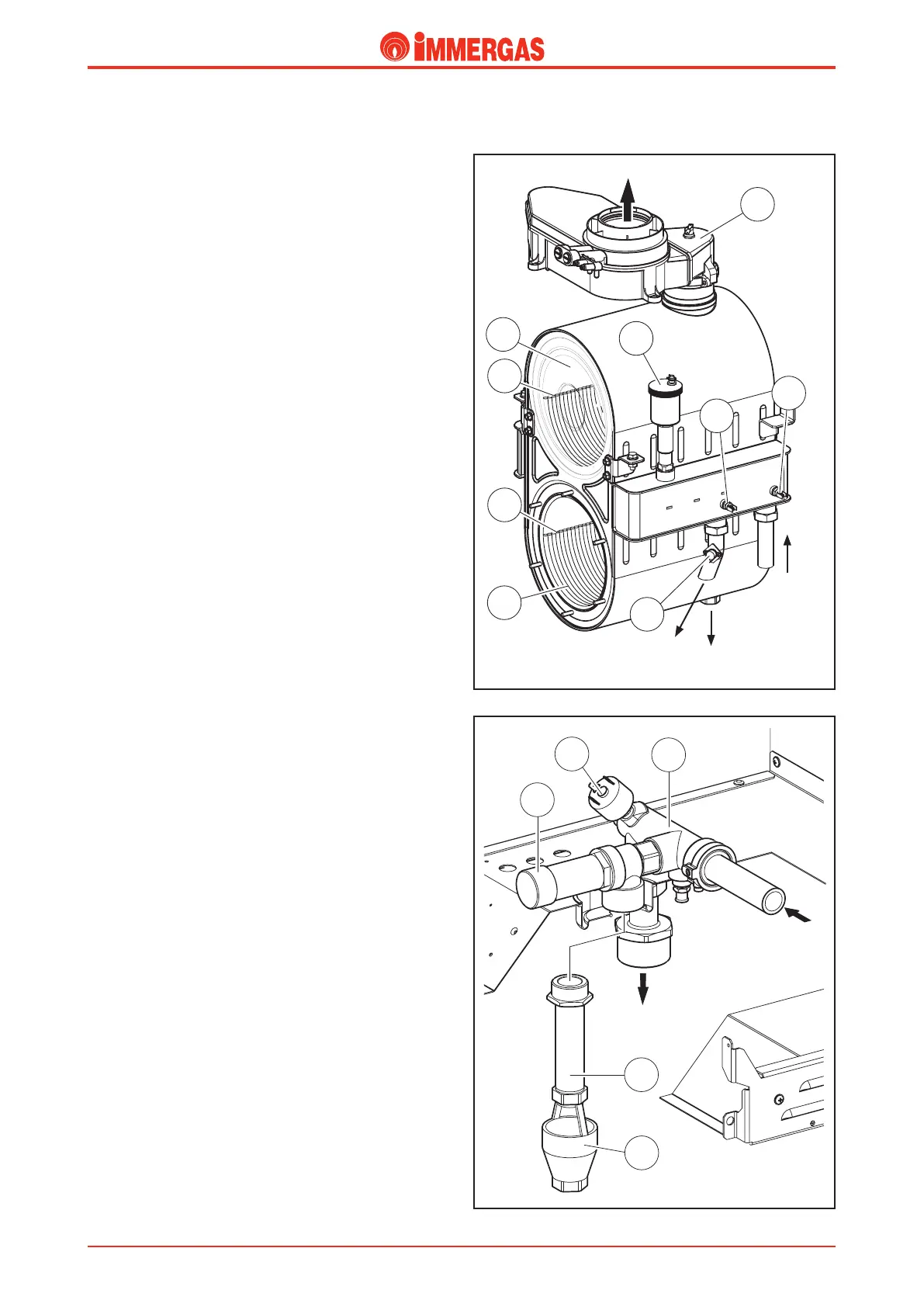

Primary heat exchanger

(condensation module).

It consists of a casing containing 12 coil shaped elements.

Each element is made of 5 elliptic pipe spirals (3).

e whole module is made of stainless steel. e lower sec-

tion is the sealed combustion chamber while the top is the

condensation chamber (4).

e eight lower elements are heated directly by the cylindrical

burner, while the top four are located inside the condensation

chamber (4) which is separated from the combustion chamber

by a metal plate (see the ue circuit).

To minimise head losses and increase the ow available for

the system, the ow consists of the parallel connection of six

elements while the return consists of the parallel connection

of the remaining six elements.

e exchanger inlet is connected to the boiler pump ow on

which the system return NTC probe is positioned (6) while the

outlet, on which the system ow (7) NTC probe is positioned,

is connected to the primary circuit ow.

readed ttings and a at seals are used to couple the ow

and return pipes of the primary circuit.

e overheating safety thermostat (1) is installed on the system

ow pipe.

e ue hood (5) is connected to the top of the module by a

seal and fastened to the supporting frame by screws.

Condensation is runo from the bottom.

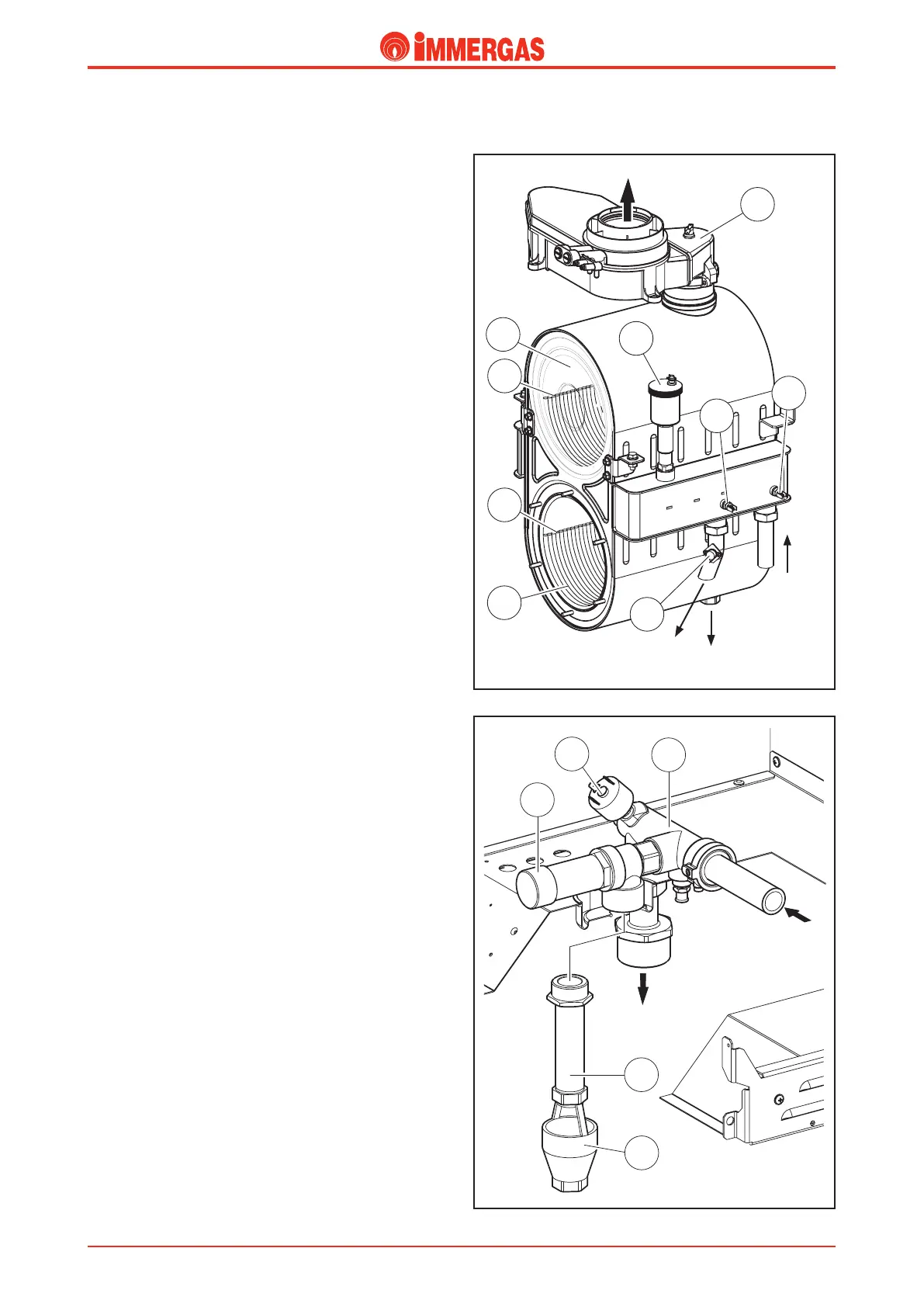

Safety devices and controls.

System pressure switch (2).

is switch detects the pressure inside the primary circuit.

It is housed on the ow manifold body and coupled to a

microswitch that prevents the burner working when pressure

is below 0.3 bar.

It prevents the main exchanger from overheating.

ISPESL type approved 4 bar safety valve (3).

It prevents the safety pressure from being exceeded in the

circuit (4 bar).

It is located at the front of the ow manifold body to which

it is coupled.

When this valve trips it causes water to come through the

system ow pipe to which an extension pipe (4) is connected

that ends with a collection funnel (5).

System

ow

Flue

Condensate

discharge

System

return

System

ow

Technical Documentation

Technical Documentation

Loading...

Loading...