16

STV75 ed 01/08 VICTRIX 75

Air inlet and exhaust kits.

e kits with relative accessories permit use of two concentric

systems.

As regards the load losses relating to each accessory and the

various possible combinations see the instructions concerning

the air inlet and exhaust end pieces.

e coupling of the various accessories (curves, extensions, end

pieces) are of the push tting and sealing is ensured by EPDM

peroxide lip seals resistant to the action of condensate.

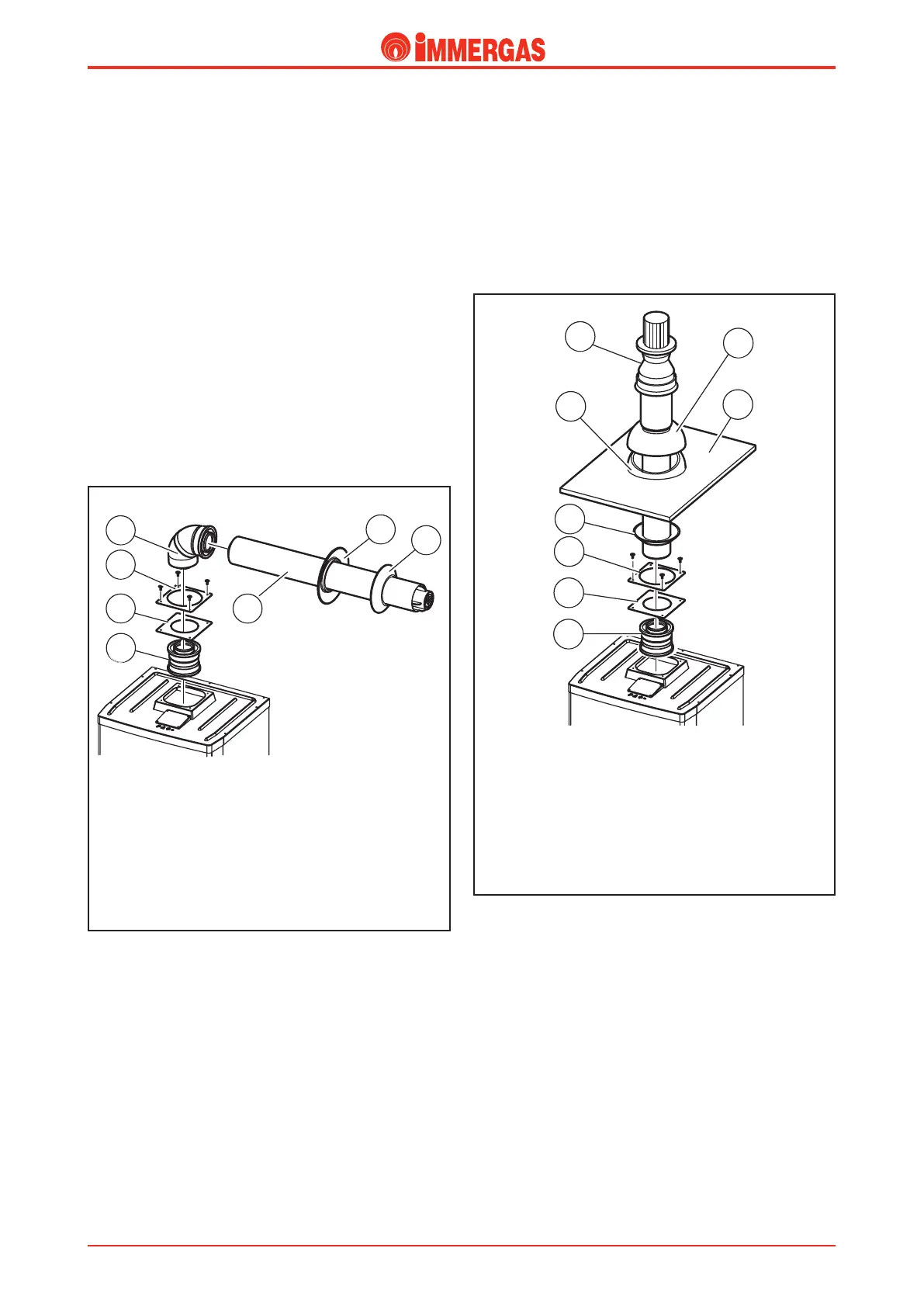

80 /125 push tting horizontal concentric kit.

e PPS exhaust pipe (80 mm Ø) is tted inside the plastic

air inlet pipe (125 mm Ø).

Connection to the boiler is done using a concentric adapter

80/125 Ø (1) on which a 90° curve is tted (4) adjustable in

any direction and which, with the necessary extensions, is con-

nected to the specic air inlet and exhaust end piece (5).

e overall maximum length permitted beyond the rst curve

(4) is 14 straight horizontal metres.

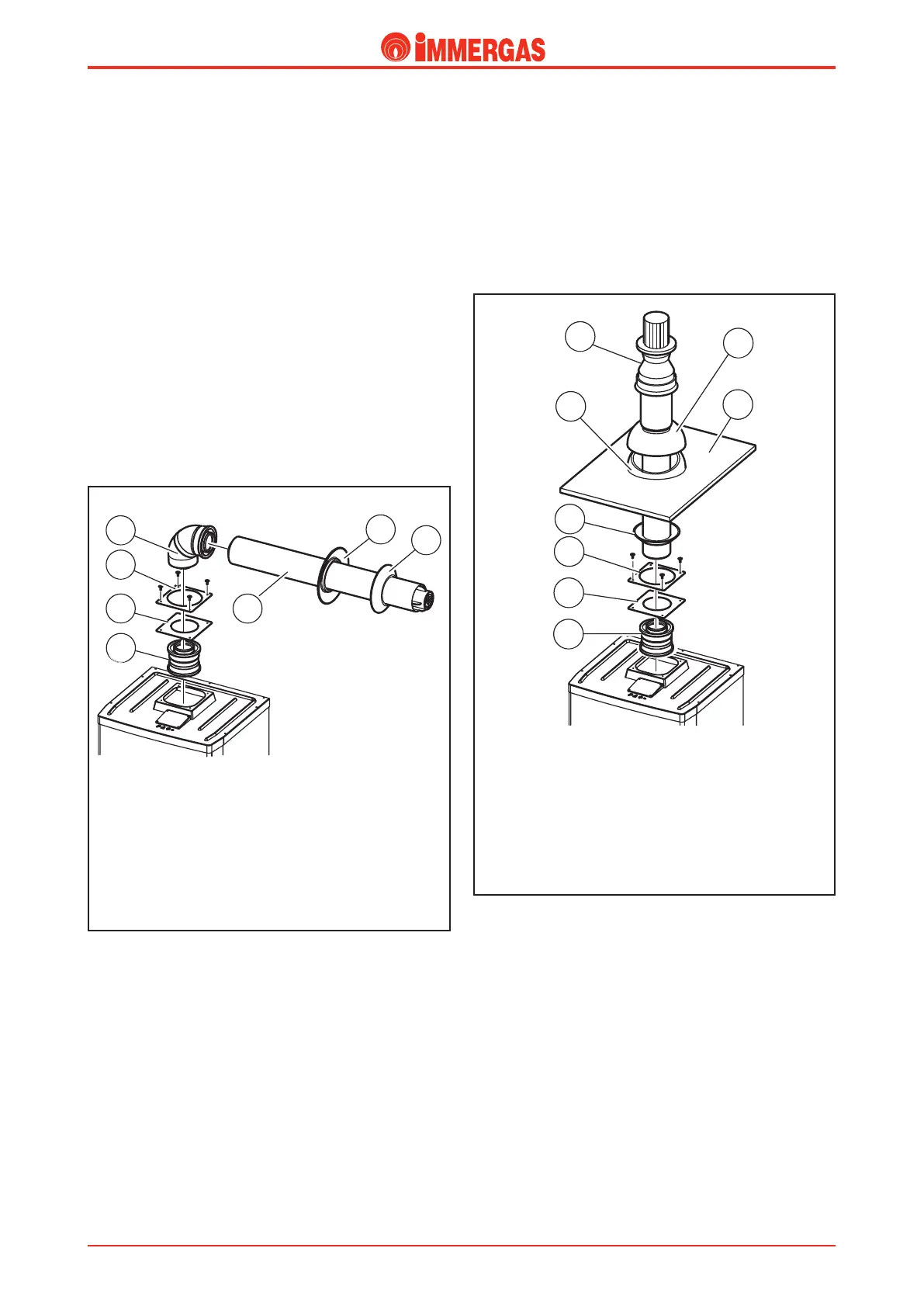

80 /125 push tting vertical concentric kit.

e PPS exhaust pipe (80 mm Ø) is tted inside the plastic

air inlet pipe (125 mm Ø).

Connection to the boiler is done using a concentric adapter

80/125 Ø (1). Any extensions needed are connected to the

specic air inlet and exhaust end piece 80/125 (7) with alu-

minium tile (5).

e overall maximum length permitted is 18 straight verti-

cal metres.

Inside the kit you will nd:

No.1 - Adapter 80/125 Ø (1)

No.1 - Seal (2)

No.1 - Concentric curve 80/125 Ø at 87° (4)

No.1 - Concentric air inlet/exhaust end piece 80/125 Ø (5)

No.1 - Internal washer (6)

No.1 - External washer (7)

Inside the kit you will nd:

No.1 - Adapter 80/125 Ø (1)

No.1 - Seal (2)

No.1 - Washer (4)

No.1 - Aluminium tile (5)

No.1 - Fixed half shell (6)

No.1 - Concentric air inlet/exhaust end piece 80/125 Ø (7)

No.1 - Moveable half shell (8)

Technical DocumentationTechnical Documentation

Loading...

Loading...