18

STV75 ed 01/08 VICTRIX 75

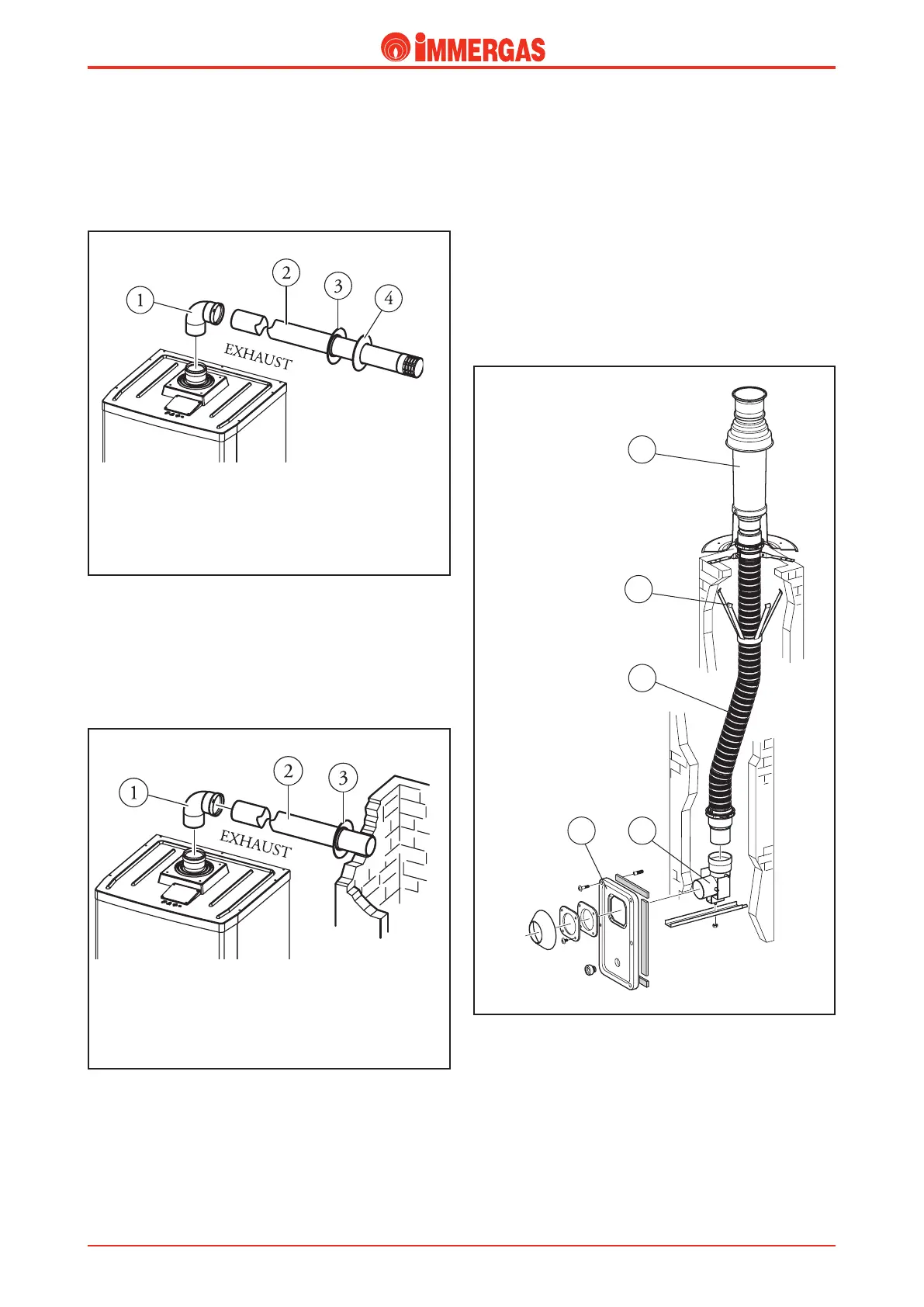

Inside the kit you will nd:

No. 1 - 80 Ø 90° curve (1)

No. 1 - 80 Ø exhaust end piece (2)

No.1 - Internal washer (3)

No.1 - External washer (4)

Inside the kit you will nd:

No. 1 - 80 Ø 90° curve (1)

No. 1 - 80 Ø exhaust pipe (2)

No.1 - Internal washer (3)

80 Ø horizontal kit with wall discharge.

A 90° curve (1) is used for connecting to the boiler that can be

turned in any direction and which, using the necessary extensions,

is connected to the relative exhaust end piece (2) made of PPS.

e maximum permitted length beyond the rst curve (2) is

30 straight horizontal metres.

80 Ø horizontal kit with ue discharge.

A 90° curve (1) is used for connecting to the boiler that can be

turned in any direction and which, using the necessary extensions,

is connected to the relative exhaust pipe (2) made of PPS.

e maximum permitted length beyond the rst curve (2) is

30 straight horizontal metres.

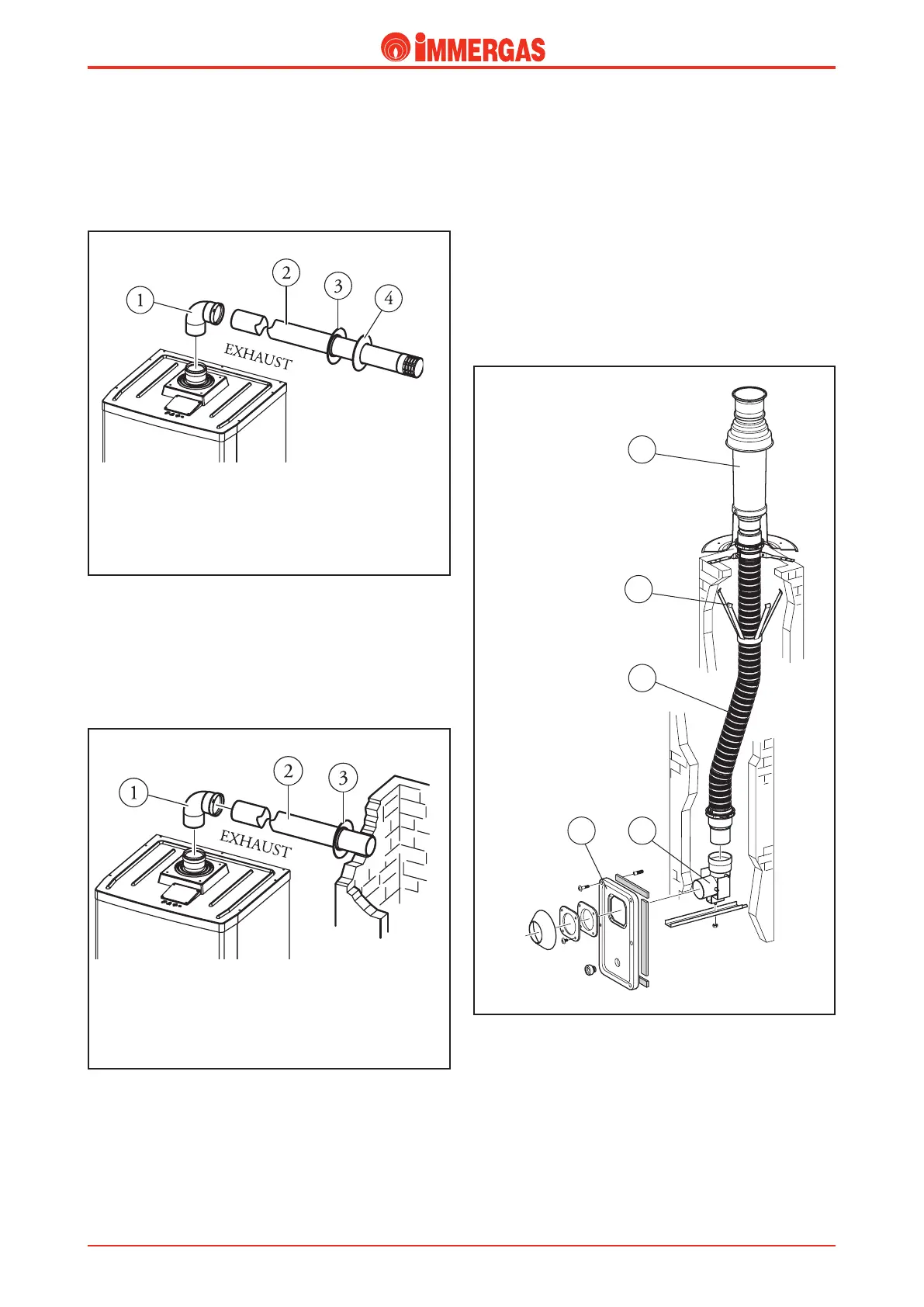

1

2

3

45

80 exible ducting system.

With this kit it is possible to duct 80 Ø pipes of existing

ues/stacks/technical slots to be used with one Immergas

condensation boiler only.

It is connected to the boiler’s exhaust pipe with an 87° curve

(4) that, with the necessary vertical extensions (3), is connected

to the relative exhaust end piece (1).

Remember to insert some nned spacers (2) which helps centre

the exhaust pipe inside the old stack.

e system can be inspected through the hatch (5) on the

opening that connects to the boiler’s ue extracting pipe.

e maximum permitted length is 30 straight vertical me-

tres.

Technical DocumentationTechnical Documentation

Loading...

Loading...