14

STZSkW ed 12/07 ZEUS Superior kW

Technical DocumentationTechnical Documentation

Gas adjustments.

In order to adjust maximum and minimum gas pressure it is

necessary to act on the valve. Any adjustments must comply

with the values indicated in the charts regarding each boiler

for the type of used gas (see the technical data sheets).

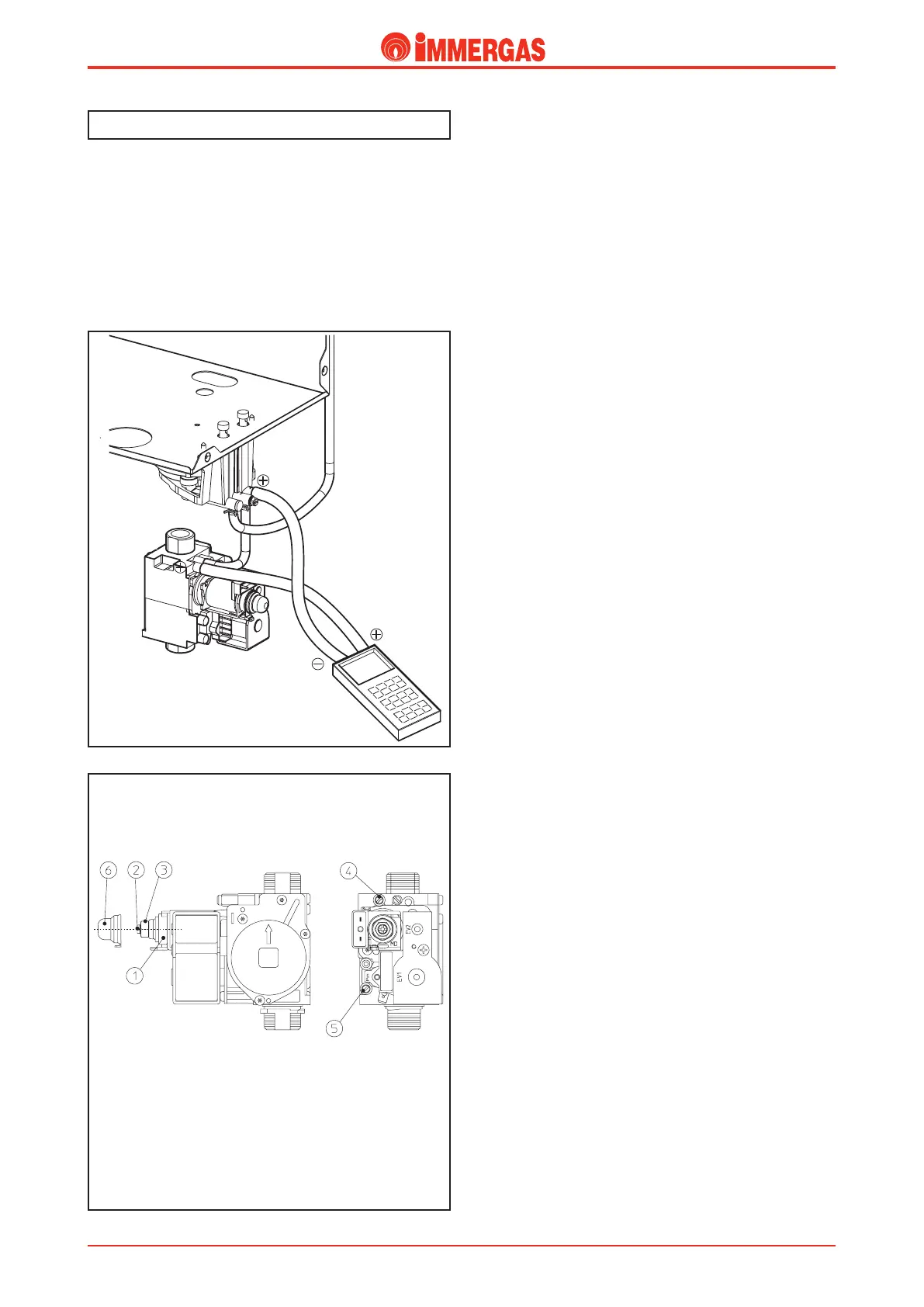

Use a dierential gauge to carry out any measurements. Con-

nect the positive pressure point to the gas valve outlet (4) and

to the positive pressure point present in the ue ow meter

support found under the sealed chamber (see gure).

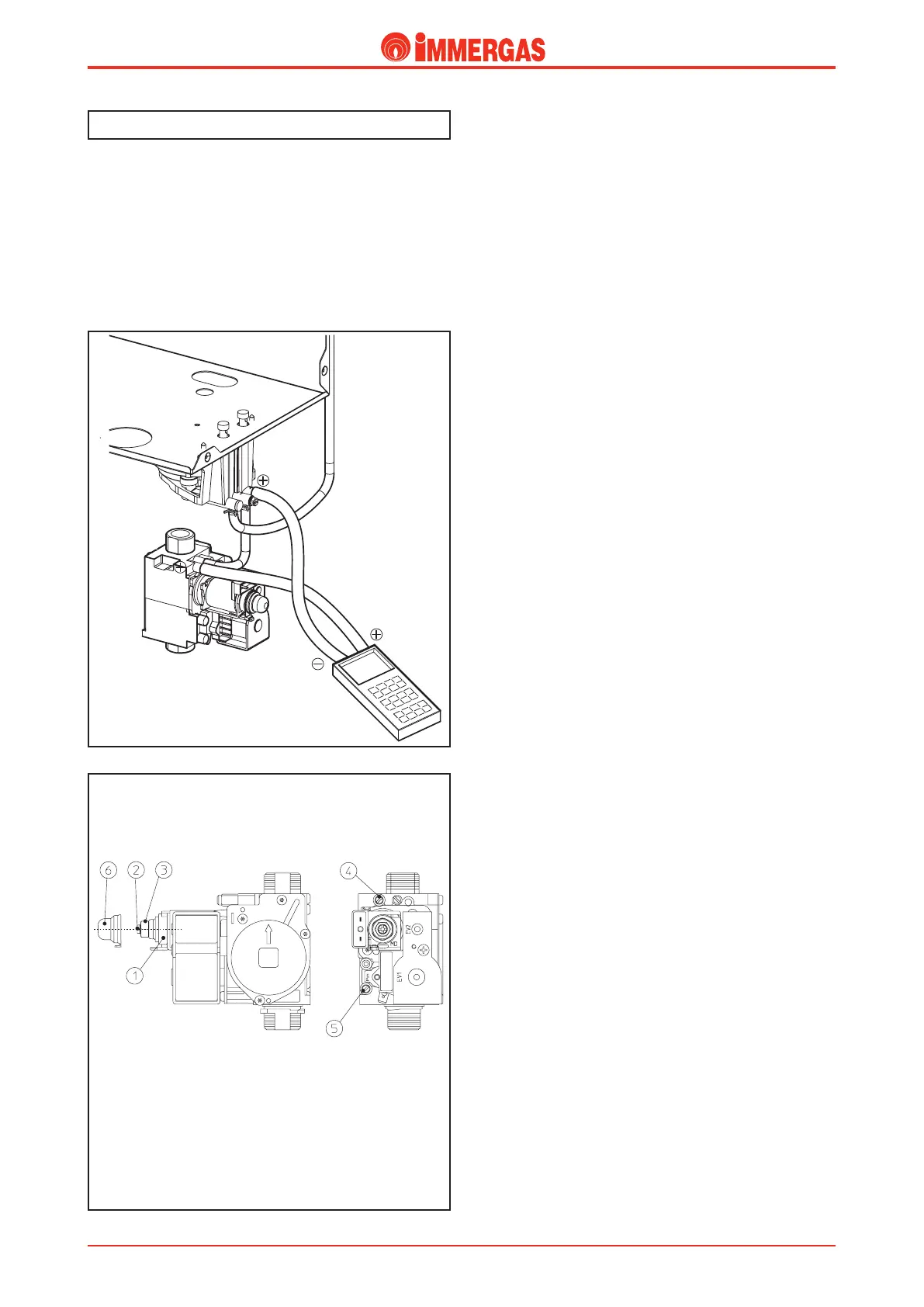

Key:

1 - Coil

2 - Minimum power regulation screws

3 - Maximum power regulation nut

4 - Gas valve outlet pressure socket

5 - Gas valve inlet pressure socket

6 - Protective hood

SIT 845 valve

SIT 845 gas valve.

Maximum pressure adjustment.

Set the DHW temperature selector to maximum output and

then open a tap.

Turn the brass nut (3) clockwise to increase the burner pressure

and anti-clockwise to decrease.

Minimum pressure adjustment.

(First, adjust maximum pressure and then minimum pressu-

re). Disconnect power supply from the modulation coil; then

turn the screw (2) clockwise to increase the burner pressure

and anti-clockwise to decrease it.

Gas transformation.

e adaptation to the type of gas dierent to that for which

the boilers are prepared as per standard is performed using the

relevant kit (natural gas or LPG).

e transformation consists in the replacement of the burner

nozzles and modication of the "P56" parameter, which can

be programmed on the integrated circuit board (see integrated

P.C.B. programming).

e domestic hot water minimum and maximum pressures

are therefore adjusted on the gas valve in the way described

above.

e adjustments of the maximum and minimum powers in the

heating phase can be set through the parameters (see integrated

P.C.B. functioning).

e ignition pressure of the burner is not adjusted as the

particular functioning of the boarddoes not require this type

of calibration (see integrated P.C.B. functioning).

Loading...

Loading...