iDrive2 inverters Fault tracking

65

6 Fault tracking

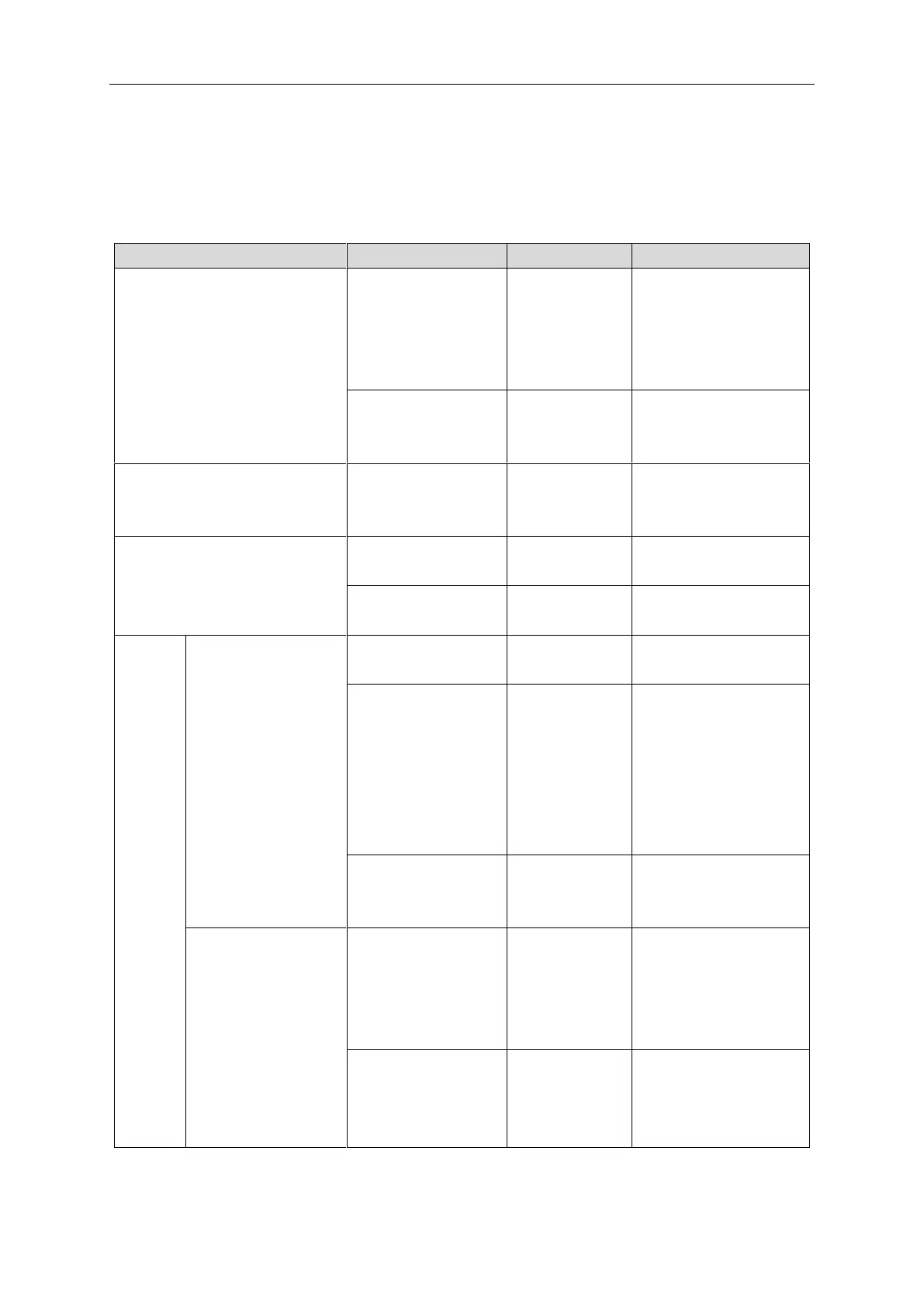

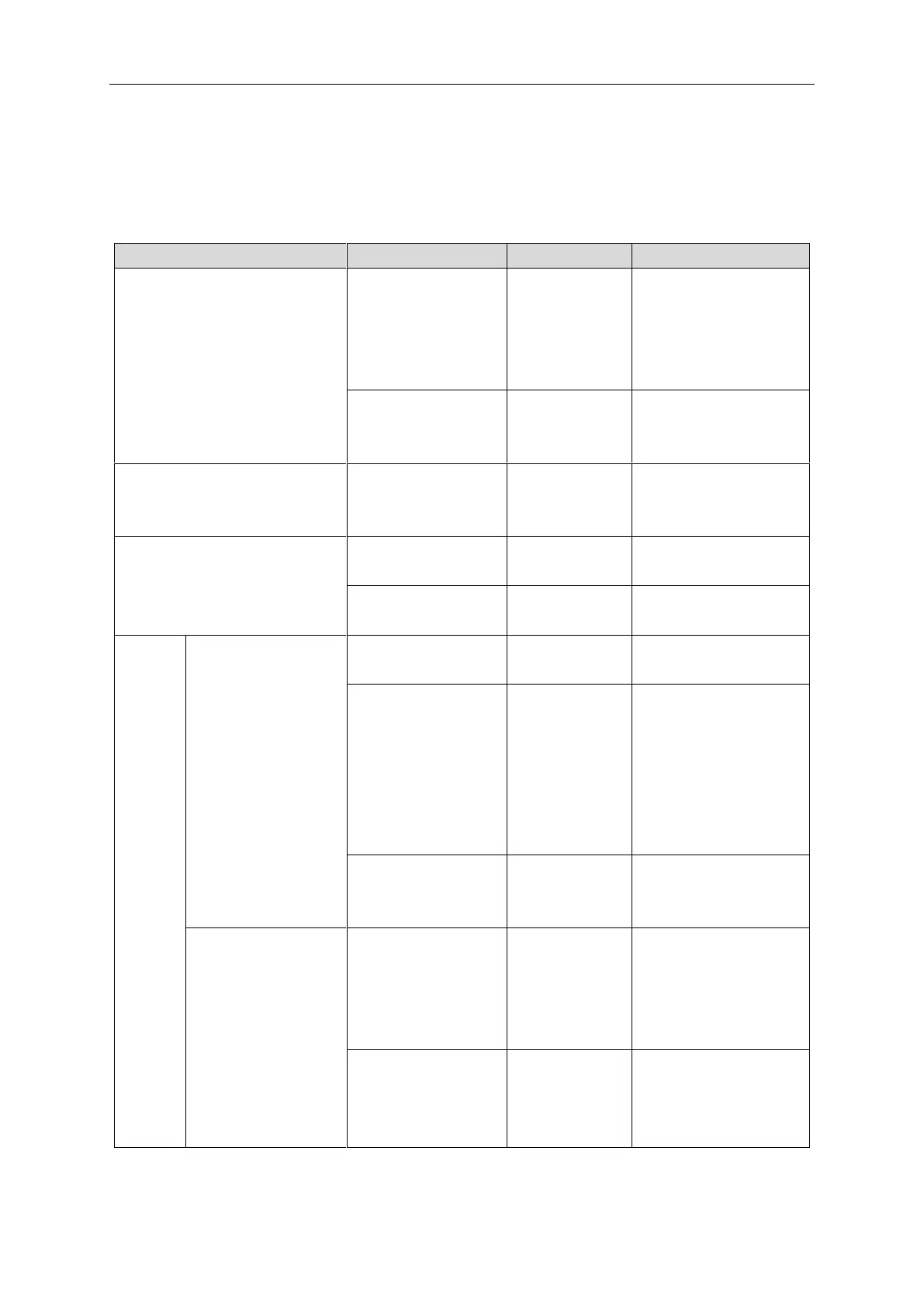

6.1 Maintenance intervals

If installed in an appropriate environment, the inverter requires very little maintenance. The table lists the routine

maintenance intervals recommended by IMO.

Check the ambient

temperature, humidity

and vibration and ensure

there is no dust, gas, oil

fog and water.

Ensure there are no tools

or other foreign or

dangerous objects

There are no tools or

dangerous objects.

Ensure the main circuit

and control circuit are

normal.

Measurement by

multi-meter

Ensure the display is

clear and legible

The characters are

displayed normally.

Ensure the characters

are displayed correctly

Ensure the screws are

tightened securely

Ensure there is no

distortion, cracks,

damage or

color-changing caused

by overheating and aging

to the machine and

insulator.

Ensure there is no dust

and dirt

Note:Discolouration of

copperwork is normal and

does not represent a fault.

The lead of the

conductors

Ensure that there is no

distortion or

color-changing of the

conductors caused by

overheating.

Ensure that there are no

cracking or

color-changing of the

protective layers.

Loading...

Loading...