iDrive2 inverters Product overview

8

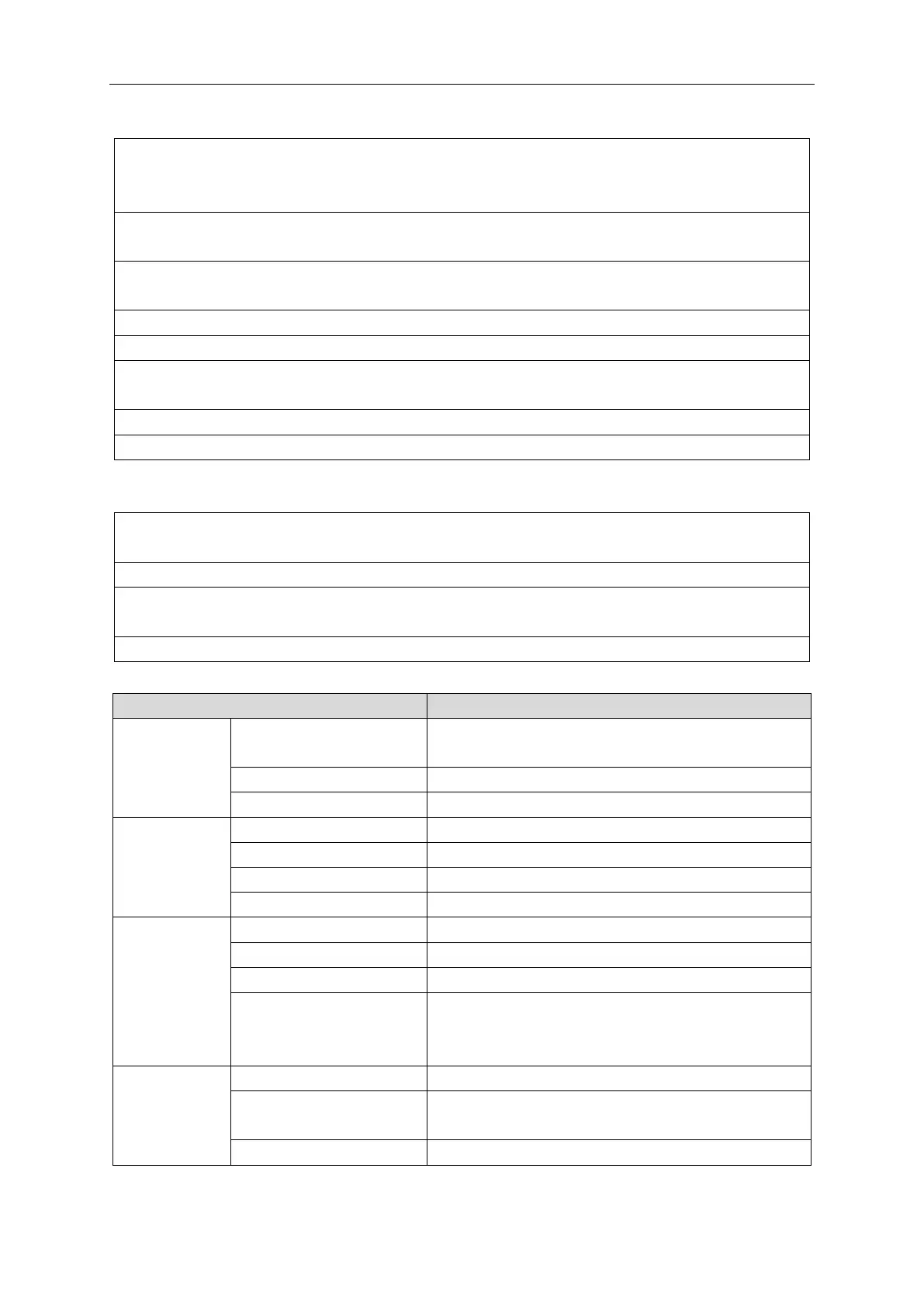

2. Check that the accessories of the inverter are correctly and properly installed. The installation cables should

meet the needs of every component (including reactors, input filters, output reactors, output filters, DC reactors

and braking resistors).

3. Check that the inverter is installed on non-flammable materials and the calorific accessories (reactors and

brake resistors) are away from flammable materials.

4. Check that all control cables and power cables are run separately and the routed to comply with EMC

requirements.

5. Check that all grounding systems are properly grounded according to the requirements of the inverter.

6. Check that the free space during installation is sufficient according to the instructions in user’s manual.

7. Check that the installation conforms to the instructions in user’s manual. The drive must be installed in an

upright position.

8. Check that the external connection terminals are tightly fastened and the torque is appropriate.

9. Check that there are no screws, cables and other conductive items left in the inverter.

2.1.5 Basic commissioning

Complete the basic commissioning as follows before actual operation:

1. Autotune. If possible, de-coupled from the motor load to start dynamic autotune. Or if not, static autotune is

available.

2. Adjust the ACC/DEC time according to the actual running of the load.

3. Commission the device via jogging and check that the rotation direction is as required. If not, change the

rotation direction by changing the wiring of motor.

4. Set all control parameters to suit application.

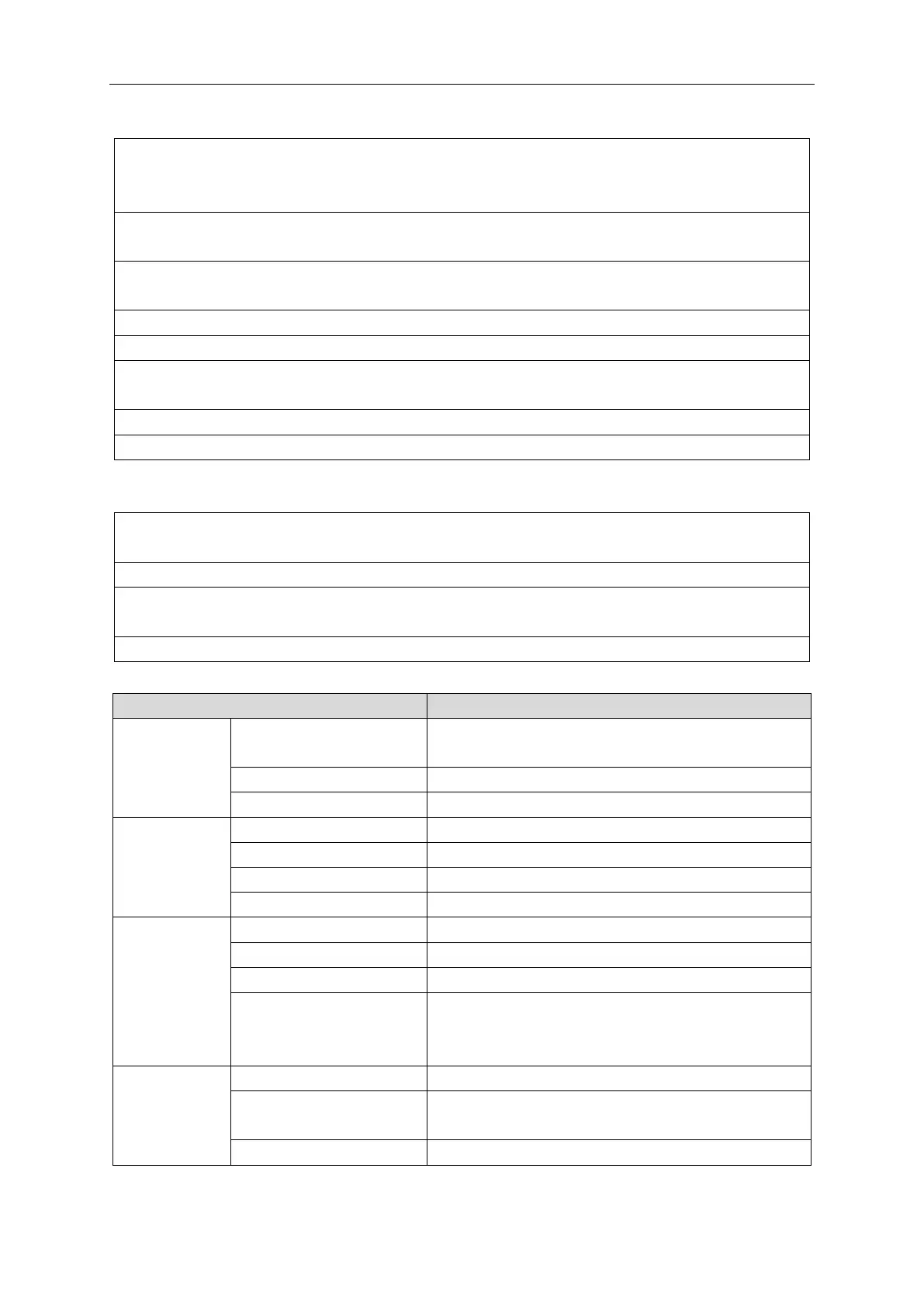

2.2 Product specification

Single-phase 220 (-15%)~240 (+10%)

Three-phase 380 (-15%)~440 (+10%)

50Hz or 60Hz Allowed range: 47~63Hz

=the input voltage (error<5%)

50Hz/60Hz, fluctuation:±5%

150% of rated current: 1 minute

180% of rated current: 10 seconds

200% of rated current: 1 second

Stop mode and anti-overtemperature of the bus

Temperature measurement

accuracy

Overtemperature point ±3℃

Loading...

Loading...