35

Coolant Coolers

Following are instructions for removal and internal

cleaning of coolant/aftercooler.

1) Remove right side panel.

2) Remove 6 screws in right side plenum wall and

remove plenum wall.

3) Remove 8 screws in left side plenum wall and remove

plenum wall.

4) Remove hose from aftercooler discharge (right side)

and plug hole.

5) Disconnect tube from aftercooler inlet (left side).

Loosen tube nut on opposite end of tube and rotate

tube away. Plug hole in aftercooler.

6) Loosen hose nuts 1/4 turn on oil cooler inlet and outlet

hoses.This will allow hose fittings to swivel without

causing kink in hose.

7) Remove 6 screws in cooler support panel to allow

cooler to swing out on hinges.

8) Cover opening that exposes fan and fan motor to

ensure water does not spray onto motors.

9) Before cleaning coolers, check to ensure all

connections are plugged to prevent contamination of

compressor system.

10) After cleaning is complete, reassemble in reverse

order.

11) Replace enclosure panels.

5.9-2 Water Cooled Coolers

Procedure

A periodic inspection and maintenance program

should be implemented for water cooled heat

exchangers.The following steps should be taken.

1. Inspect filters in system and replace or clean as

required.

2. Carefully examine tubes for scale and clean if

necessary. If a cleaning solution is used, be sure to

wash out all chemicals thoroughly with clean water

before returning the compressor to service. After

cleaning, examine the cooler for erosion or corrosion.

5.9 COOLER CORES: CLEANING

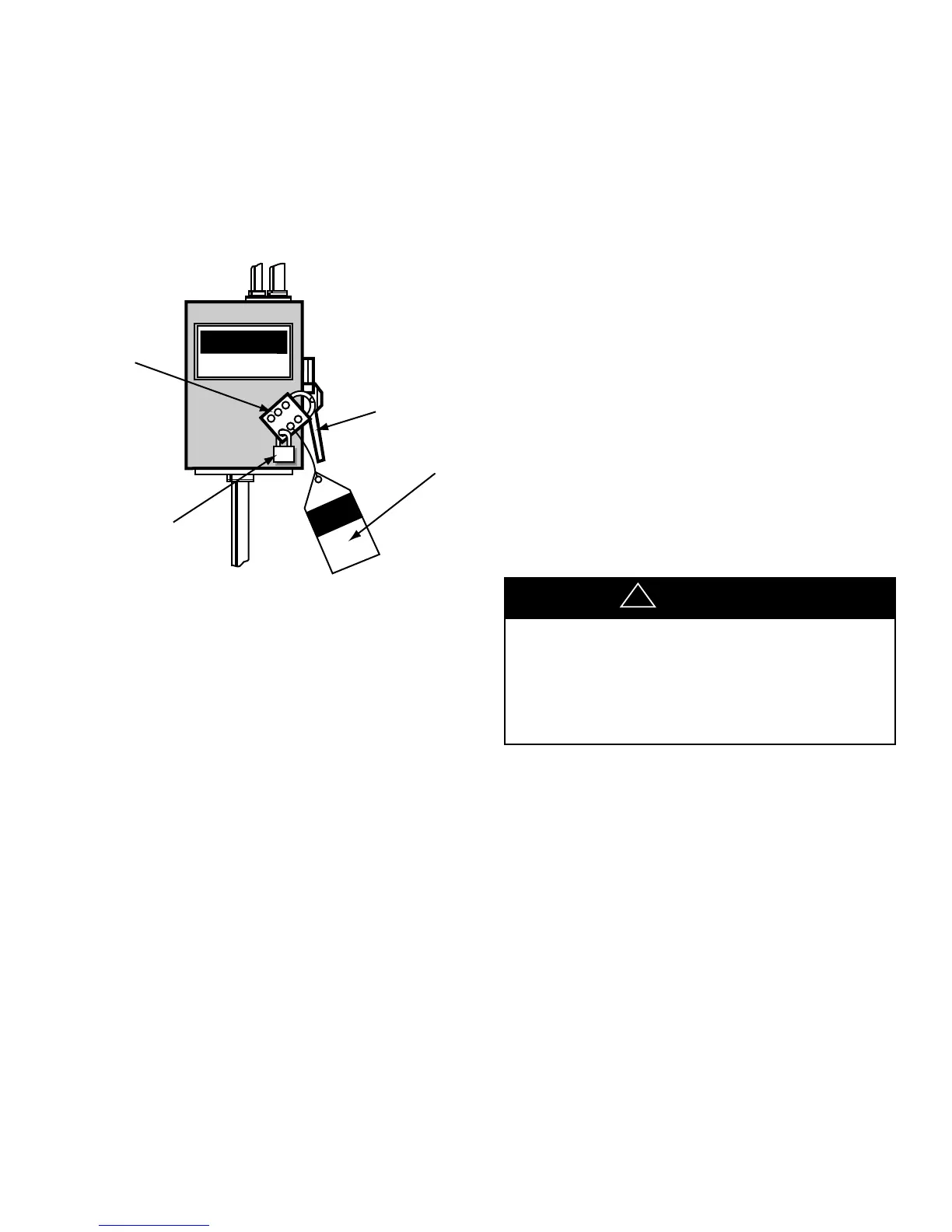

Ensure that the compressor is isolated from the

compressed air system by closing the isolation valve

and venting pressure from the drip leg.

Ensure that the main power disconnect switch is

locked open and tagged. (See Figure 5.9-1).

Tools Required

■ Screwdriver

■ Wrench set

■ Air hose equipped with approved O.S.H.A. nozzle.

On units sold outside the U.S.A. consult

local codes.

5.9-1 Air Cooled Coolers

Procedure

Visually check the outside of the cooler cores to be

certain that a complete outside cleaning of the cooler is

required. Frequently, dirt, dust or other foreign material,

may only need to be removed with an air hose to remedy

the problem.

When the cooler is covered with a combination of

oil, grease or other heavy substances that may

affect the unit’s cooling, then it is recommended

that the cooler cores be thoroughly cleaned on the

outside.

If it is determined that the compressor operating

temperature is higher than normal due to the internal

passages of the cooler cores being restricted with

deposits or foreign material, then the cooler should be

removed for internal cleaning.

Strong cleaners can harm

aluminum cooler parts. Follow cleaner

manufacturer’s instructions for use.

Wear appropriate safety equipment.

CAUTION

Loading...

Loading...