5.11 LONG TERM STORAGE

General

The factory, upon special request, prepares compressor

units for long term storage. In such cases, a special

bulletin is supplied for storage and start-up procedures.

The bulletin provides special procedures for rotation and

lubrication of compressors during storage.

Before actual start-up of the compressor, the unit must

be drained of coolant containing vapor space inhibitors.

Procedure for long term storage start-up is covered in the

special bulletin APDD 339.

5.12 COOLANT/LUBRICANT CHANGEOUT

Ingersoll-Rand does not recommend changeout of

coolant/lubricants, however, if a coolant/lubricant

change cannot be avoided, procedure APDD 106E-87

should be obtained from your Ingersoll-Rand

representative.

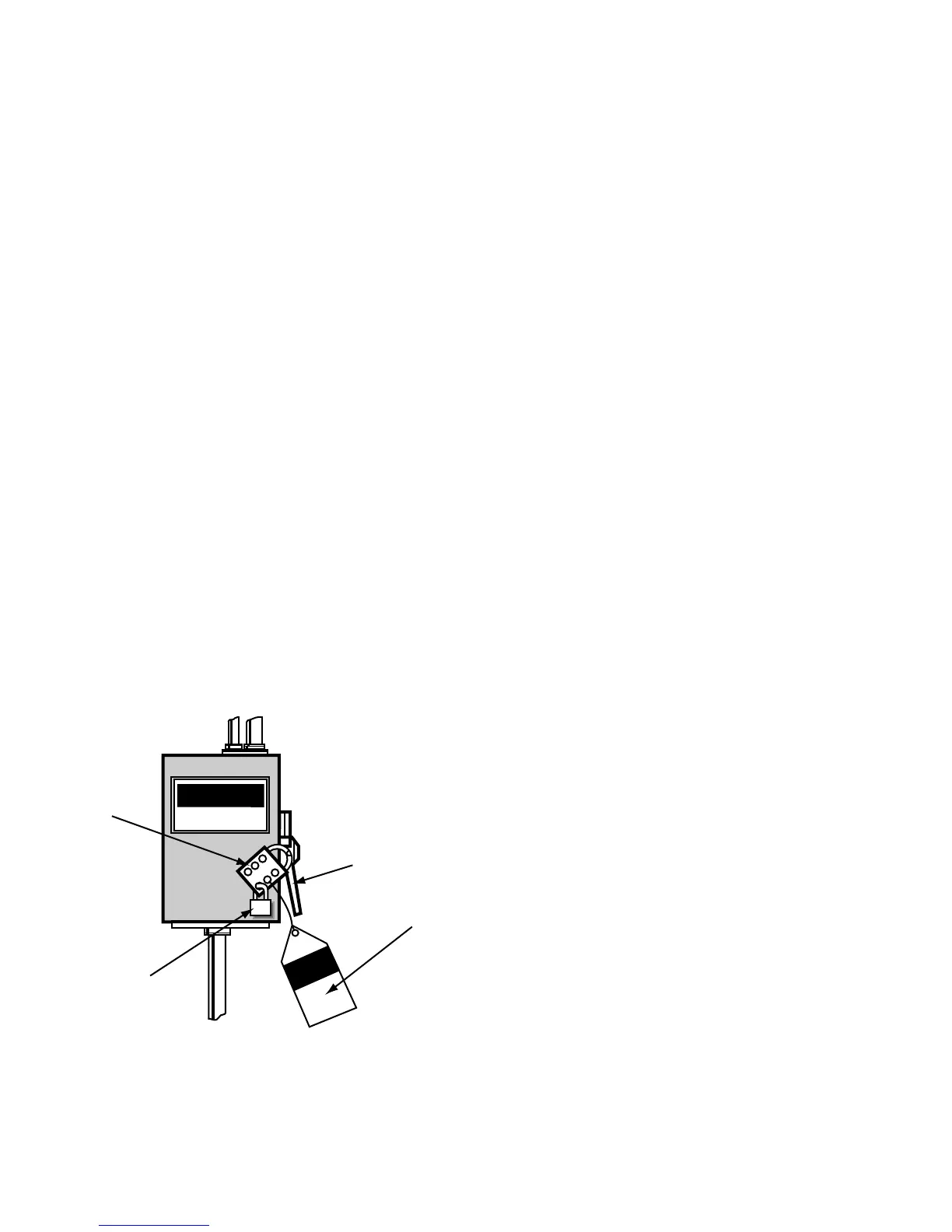

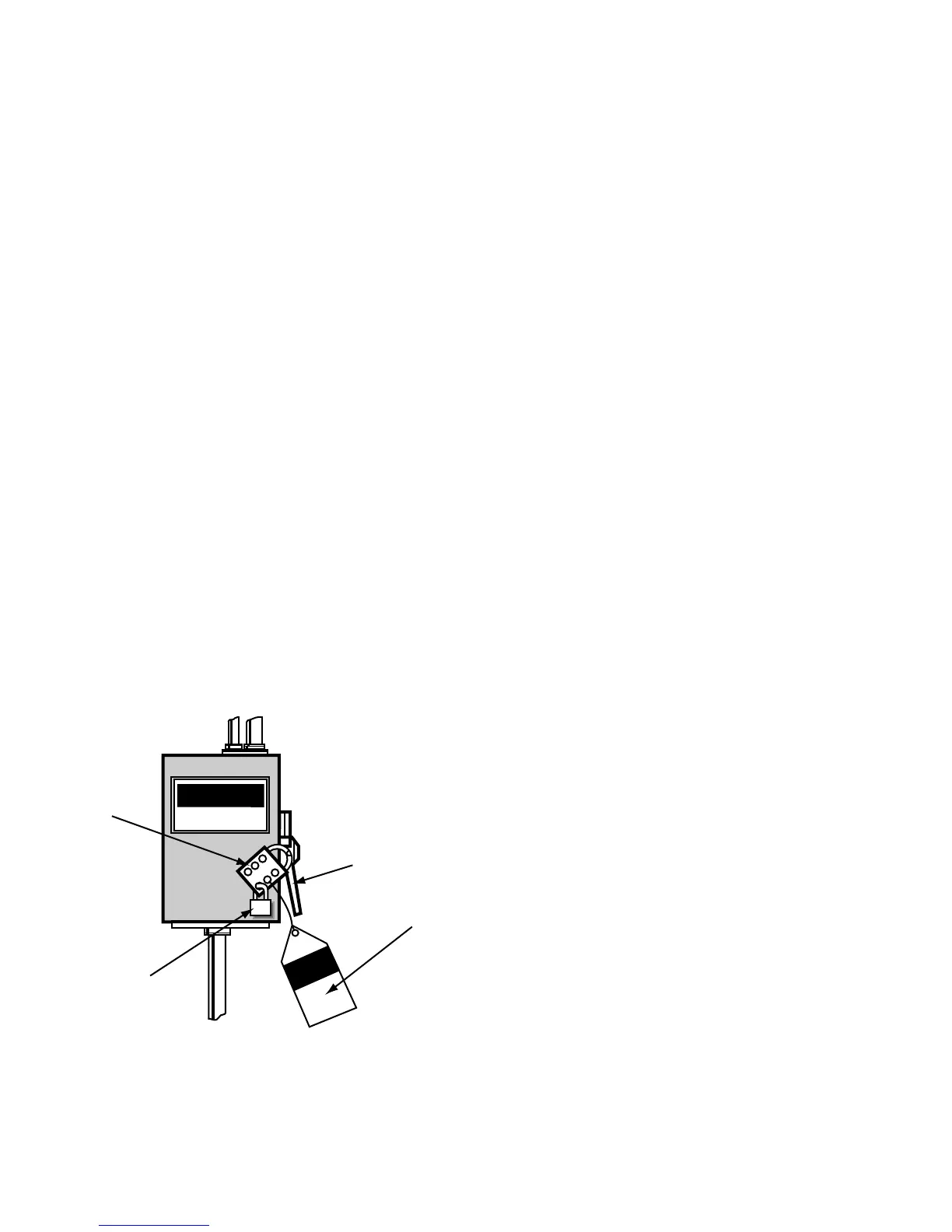

5.13 INTELLISYS REMOVAL

Ensure that the compressor is isolated from the

compressed air system by closing the isolation

valve and venting pressure from the drip leg.

Ensure that the main power disconnect switch is

locked open and tagged (See Figure 5.13-1).

FIGURE 5.13-1 MAIN DISCONNECT

LOCKED AND TAGGED

Follow these precautions to minimize damage from

static electricity. Static can cause severe damage to

microcircuits.

1) Make the least possible movement to avoid build-

ing up static electricity from your clothing or tools.

2) Discharge potential static electricity by touching

(grounding) yourself to the starter box.

3) Handle circuit boards only by their edges.

4) Do not place the controller or power supply

assembly on any metal surface.

5) Leave the replacement parts in their protective

bags until ready for installation.

Tools:

Screwdriver Size #1, flathead

3/8 inch hex driver

Before removing any components, open the starter box

door and check all wiring for tightness. A loose wire or

bad connection may be the cause of problems.

Controller Removal:

1) Open the starter box door.

2) Remove the five electrical plug-in connectors from

the top of the controller.

3) Remove (2) mounting rails that attach the

Intellisys® Controller at the side of the control box.

4) Remove the controller. Remove any option

modules which must be installed in the new

controller.

38

Loading...

Loading...