User’s Manual

INNO Instrument, Inc.

19

PAGE

General Splicing Steps

This section explains the steps involved in automatic splicing process and

describes how various program parameters are related to this process. The normal

splicing process can be divided into two sections: pre-fusion and fusion.

During pre-fusion, the splicer performs automatic alignment and focusing, where

the bers are subjected to a low pre-fusion current for cleaning purposes; a pre-

fusion image is also taken. At this point, the user is informed of any problems

recognized in the pre-fusion image, such as a poorly prepared ber. The splicer will

then issue a warning before the bers are fused together.

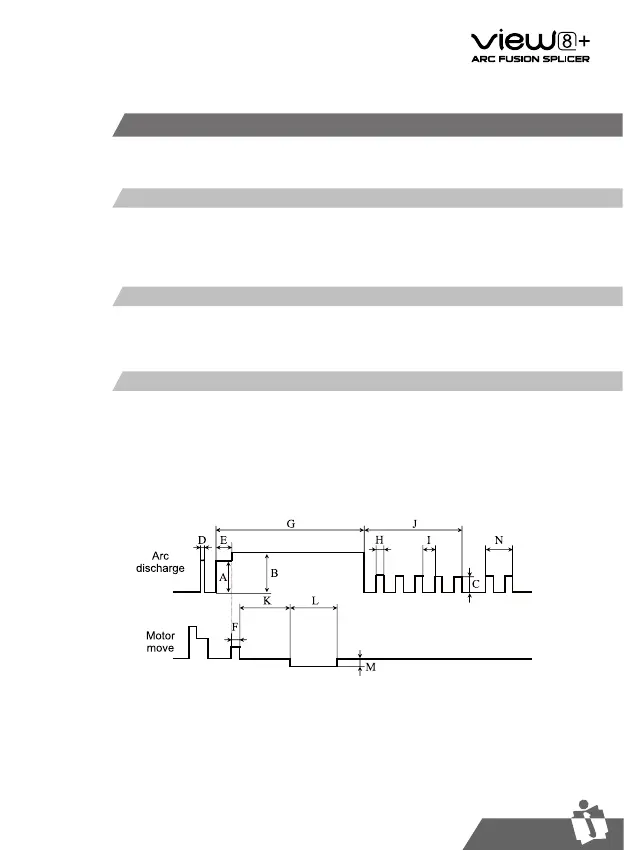

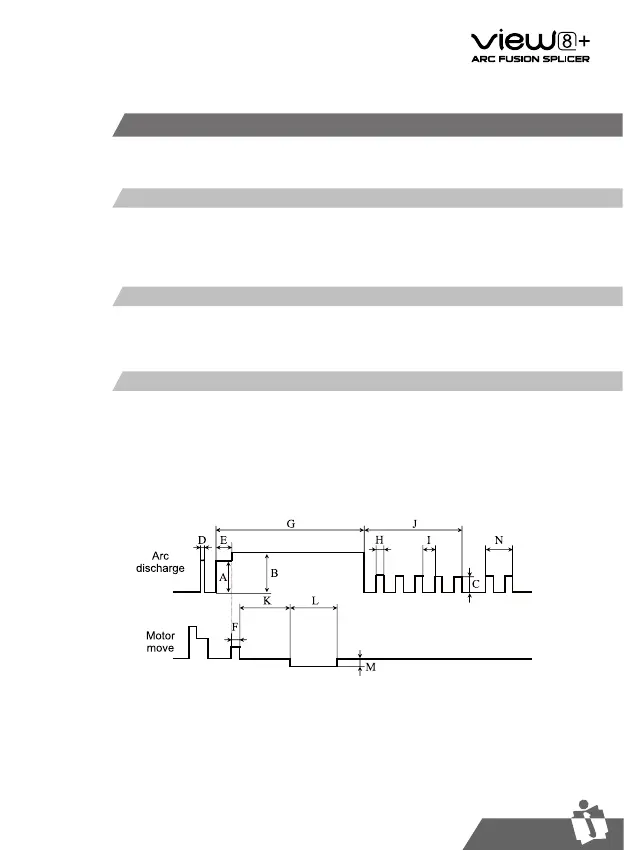

During fusion, the bers are joined together and subjected to ve different currents

as illustrated below. An important parameter, which changes during splicing, is

the distance between the bers. During Pre-fusion, the bers are apart. With the

current phase changing, bers are spliced gradually.

Arc power and arc time are considered as the two most important parameters (as

shown in the gure below). The name and purpose of those parameters as well as

the effect and importance of the parameters will be described in the next section

“Splice program parameters under general splicing process”. The below figure

shows the arc discharge conditions (relationship between “Arc power” and “Motor

motion”). These conditions can be modied by changing the splicing parameters

listed below. However, depending on the splice mode, certain parameters cannot

be changed.

Diagram of ARC discharge condition

A: Pre-fuse power B: Arc1 power C: Arc2 Power D: Cleaning Arc

E: Pre-fuse Time F: Forward Time related to Overlap G: Arc1 time

H: Arc2 ON time I: Arc2 OFF time J: Arc2 time

K: Taper Splicing Wait Time L: Taper Splicing Time

M: Taper Splicing speed N:Rearc Time

Pre-Fusion

Fusion

Splicing Process

Loading...

Loading...