User’s Manual

INNO Instrument, Inc.

22

PAGE

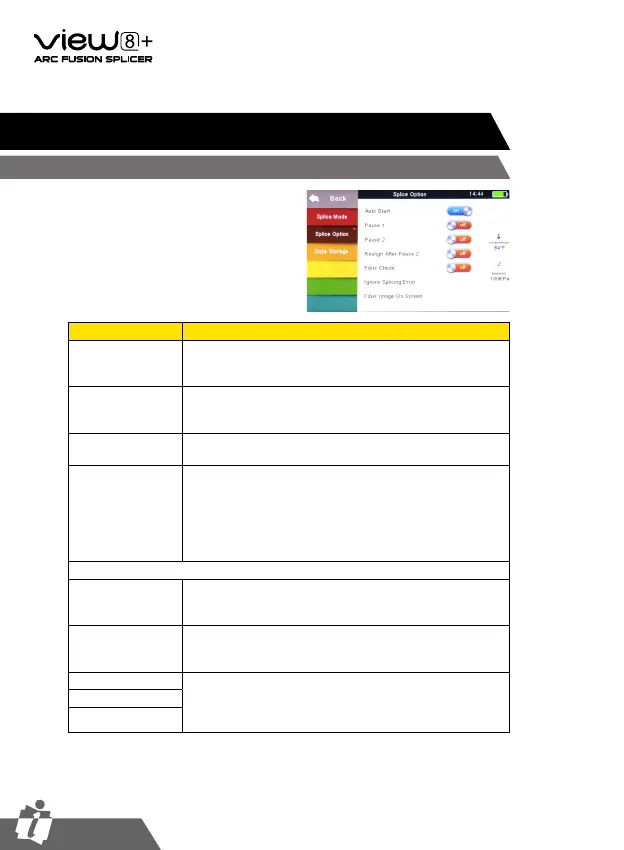

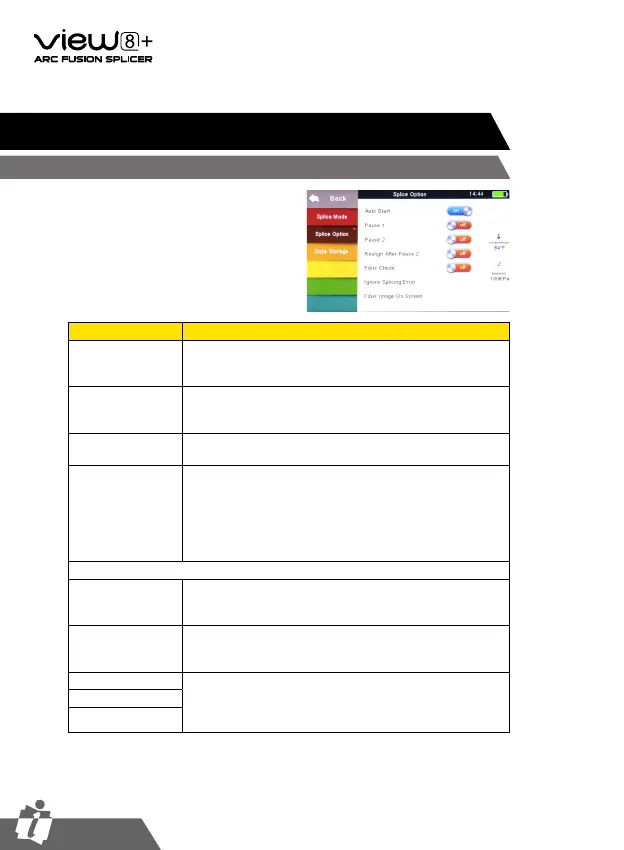

1 Select [Splice option] in menu.

2 Select a parameter to be changed.

Chapter 5 - Splice Option

Splice Mode Setting

Parameter Description

Auto start

If “Auto start” is set to ON, splicing starts automatically

as soon as the wind protector is closed. Fibers should be

prepared and placed into the splicer in advance.

Pause 1

If “Pause 1” is set to ON, splicing operation pauses when

fibers are forwarded to gap-set position. Cleave angles are

displayed during the pause.

Pause 2

If “Pause 2” is set to ON, splicing operation pauses after

fiber alignment is completed.

Realign after pause

2

Alignment failure may appear after “Pause2” for a long

period. Therefore, realign after “Pause2” is needed.

Setting to “OFF” will prevent the implementation of

realign function. Manual splicing, rather than setting the

realign to “OFF”, is recommended when there is an axial

displacement of the splicer

Ignore splice error

Cleave angle

Setting to “OFF” ignores the faults and continues to

complete the splicing even if the message “Cleave Angle

Error” appears.

Core angle

Setting to “OFF” ignores the faults and continues to

complete the splicing even if the message “Core Angle

Error” appears.

Loss Setting to “OFF” ignores the faults and continues to

complete the splicing even if the message “Loss Error”,

“Cleave Shape Error”, “Fat Error”, or “Thin Error”

appears.

Fat

Thin

Loading...

Loading...