4 / 52 P/N 146667999-1 (ML) • REV G • ISS 19AUG19

• Obscuring the detector field of view with large objects,

such as furniture

Microwave hazards:

• Mounting surface susceptible to vibrations

• Metal surfaces reflecting microwave energy

• Water movement through plastic pipes

• Moving or vibrating objects like fans, heating or air-

conditioning ducts

AM hazards:

• Moving objects less then 1 m in front of the detector

• Small insects on the detector

• Modern fluorescent lighting in close proximity (within

1.5 m)

WARNING! The equipment is not earthed. Any

external circuit connected to the equipment must be

located within the same building and connected to a

protective earthing conductor.

Wire insulation of cables connected to the equipment must

conform to IEC 60332-1-2 and IEC 60332-1-3 or IEC 60332-

2-2, depending on the wire cross sectional area, or IEC TS

60695-11-21, regardless of cross sectional area. Alternatively,

such wires must comply with UL 2556 VW-1.

The detector power supply source must be power limited at

15 W.

We recommend that the detector is regularly walk tested and

checked at the control panel.

To install the detector:

1. Lift off the custom insert (see Figure 2, items 1 and 2).

2. Using a screwdriver, carefully prise open the detector (see

Figure 2, items 3 and 4).

Caution: Do not touch the pyroelectric sensor (Figure 6).

3. Take out the cover screw (Figure 4, item 2).

4. Fix the base to the wall between 2.0 and 3.0 m (6.6 and

9.8 ft.) from the floor.

See Figure 4. In all positions use a minimum of two M4

screws from the standards DIN 7505B, DIN 96, DIN 7996,

or a screw with a head with 8 mm diameter and a flat

surface.

- For flat mounting, use screws in positions A.

- For corner mounting, use screws in position B or C.

Note: For EN 50131 Grade 3 installations, do not use

mounting position C.

- To install the pry-off tamper ST400, use mounting

positions A. ST400 mounting position is shown as item 3

in Figure 4. Open the outlet in the back plate (Figure 5,

item 2).

5. Wire the detector (see Figures 4 and 12). Use back plate

cable inlets (Figure 5, item 1) and cable gutter (Figure 5,

item 3).

6. Select the desired jumper and DIP switch settings (see

“Setting the detector” below for more information.

7. Remove the blinders and add the stickers, if required. See

“Configuring the coverage pattern” on page 6 for more

details.

8. For ceiling-mount applications, use the SB01 swivel-mount

bracket. SB01 mounting position is shown as item 1 in

Figure 4.

9. Close the cover, insert the cover screw, and place the

custom insert.

Connections

See Figure 12.

Table 1: Detector Connections

Power supply connection (9 to 15 V, 12 V

nominal)

Alarm relay output (33 Ω). Use jumper JA to

set the onboard EOL resistor in series with the

relay. See “Jumpers” below.

Tamper switch output (0 Ω). Use jumper JT to

set the onboard EOL resistor in series with the

switch. See “Jumpers” below.

This input enables and disables the LED (walk

test On/Off). Walk test mode can only be

entered when detector is in Day mode (pin 8).

Active high or low is determined by SW1-3

(see “SW1-3: Polarity” on page 5).

This input switches the detector in day (show

memory on the LED indicator) or night mode

(activates the alarm memory and clears

previous stored alarms). Active high or low

polarity is determined by SW1-3 (see “SW1-3:

Polarity” on page 5).

Fault Relay output (33 Ω). Use jumper JF to

insert one of the on-board EOL resistors in

series with the relay. See “Jumpers” below for

the correct resistor settings.

Notes

• Inputs 7 and 8 are only useable when SW1-5 is set to

Remote on. See “SW1-5: Remote functionality” on page 6.

• The LED is only enabled when SW1-6 is set to LED on.

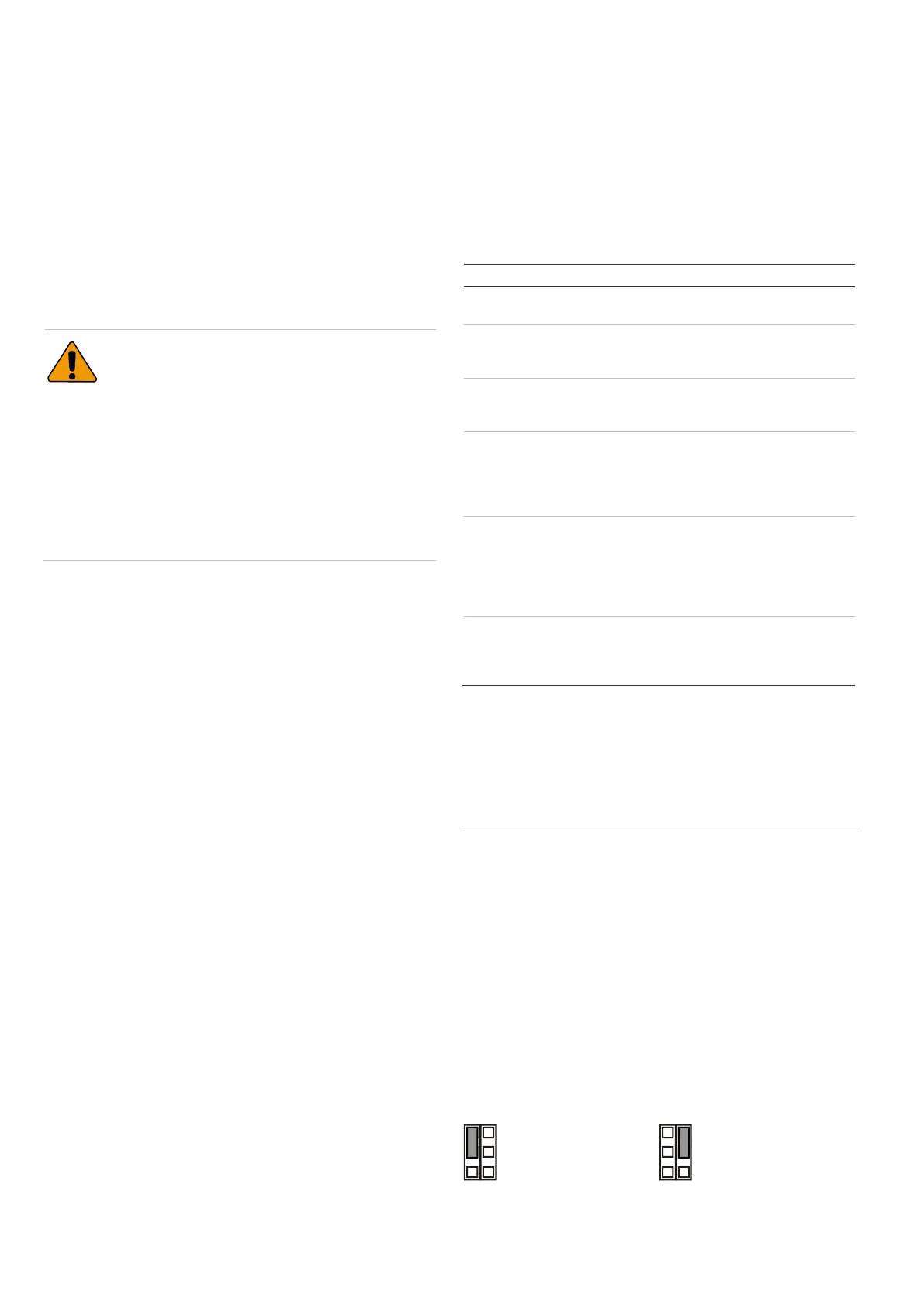

Figure 10 explains how to create a single zone with multiple

resistor configuration.

Figure 10

(1) Alarm relay

(2) Alarm zone

(3) Tamper switch output

(4) Fault relay

Ra Alarm EOL resistor

Rt Tamper EOL resistor

Rf Fault EOL resistor

Setting the detector

See Figure 13 for jumpers and DIP switch location.

Jumpers

Jumpers set onboard EOL mode and value. The circuit is

shown in Figure 10.

JA: Set onboard alarm EOL resistor (Ra)

Loading...

Loading...