Version 1.00 | Optidrive ODE-3 User Guide | 13www.invertekdrives.com

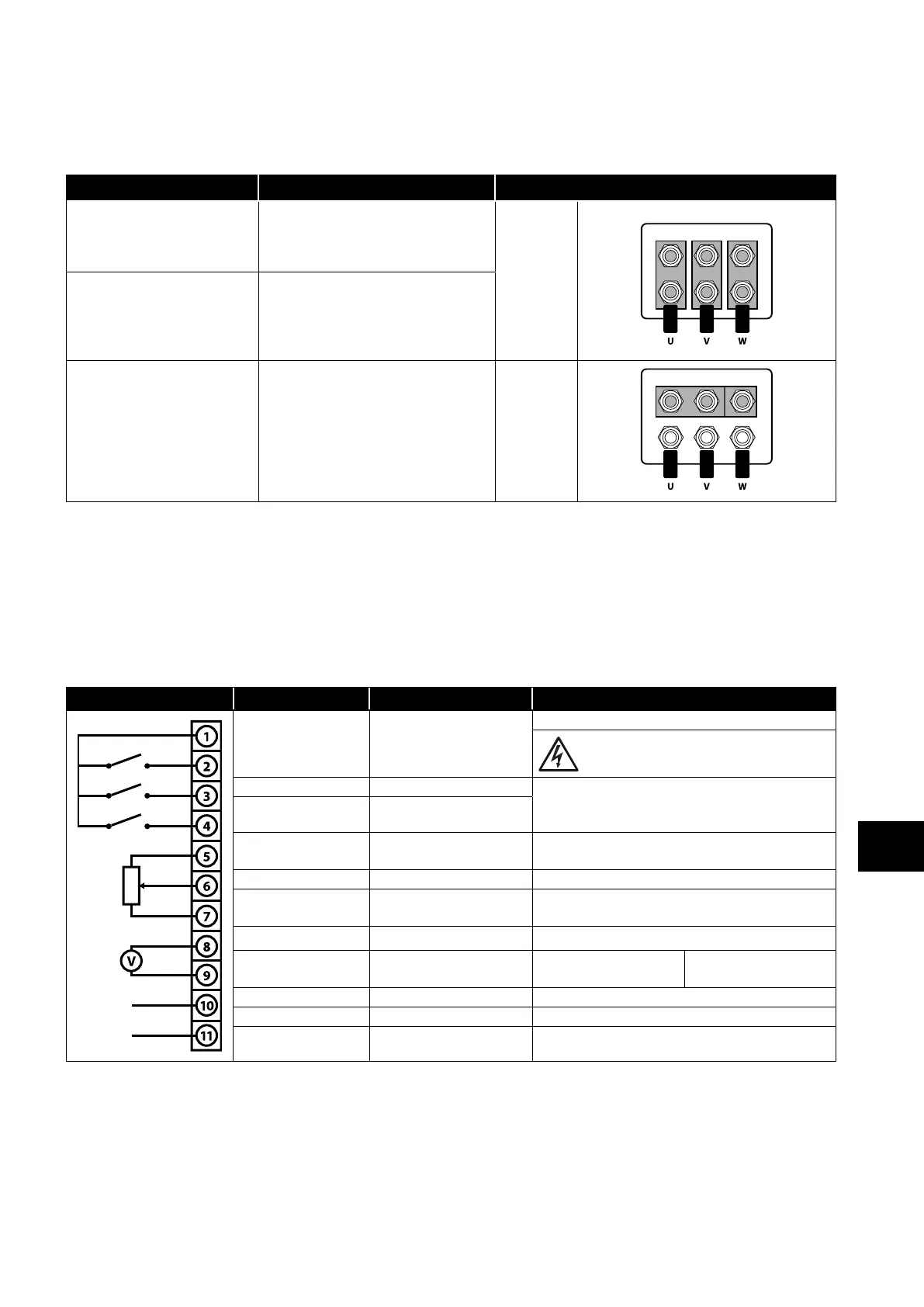

4.5. Motor Terminal Box Connections

Most general purpose motors are wound for operation on dual voltage supplies. This is indicated on the nameplate of the motor. This

operational voltage is normally selected when installing the motor by selecting either STAR or DELTA connection. STAR always gives

the higher of the two voltage ratings.

Incoming Supply Voltage Motor Nameplate Voltages Connection

230 230 / 400

Delta

∆

400 400 / 690

400 230 / 400

Star

⅄

4.6. Control Terminal Wiring

All analog signal cables should be suitably shielded. Twisted pair cables are recommended.

Power and Control Signal cables should be routed separately where possible, and must not be routed parallel to each other.

Signal levels of different voltages e.g. 24 Volt DC and 110 Volt AC, should not be routed in the same cable.

Maximum control terminal tightening torque is 0.5Nm.

Control Cable entry conductor size: 0.05 – 2.5mm2 / 30 – 12 AWG.

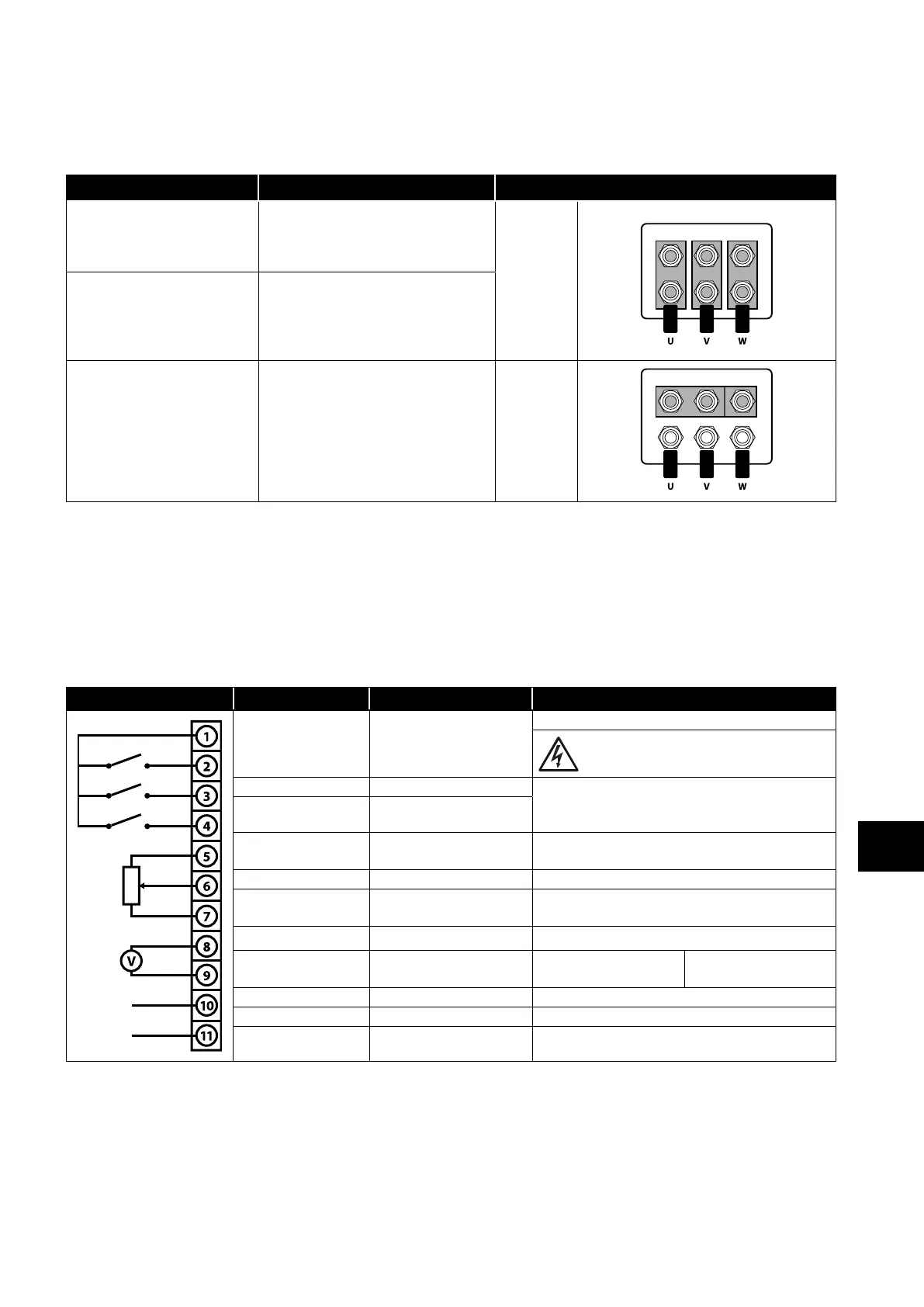

4.7. Control Terminal Connections

Default Connections Control Terminal Signal Description

1 +24Vdc User Output

+24Vdc user output, 100mA.

Do not connect an external voltage source to

this terminal.

2 Digital Input 1 Positive logic

“Logic 1” input voltage range: 8V … 30V DC

“Logic 0” input voltage range: 0V … 4V DC

3 Digital Input 2

4

Digital Input 3 /Analog

Input 2

Digital: 8 to 30V

Analog: 0 to 10V, 0 to 20mA or 4 to 20mA

5 +10V User Output +10V, 10mA, 1kΩ minimum

6

Analog Input 1 /

Digital Input 4

Analog: 0 to 10V, 0 to 20mA or 4 to 20mA

Digital: 8 to 30V

7 0V 0 Volt Common, internally connected to terminal 9

8

Analog Output /

Digital Output

Analog: 0 to 10V,

Digital: 0 to 24V

20mA maximum

9 0V 0 Volt Common, internally connected to terminal 7

10 Auxiliary Relay Common

11 Auxiliary Relay NO Contact

Contact 250Vac, 6A / 30Vdc, 5A

Intended to drive resistive load.

Power & Control Wiring

4

Loading...

Loading...