7. Maintenance and troubleshooting

Machinery maintenance technician

The machinery maintenance technician is a qualified person, with the administrator privileges required to modify

the configuration of LBK System Series through the software and to perform maintenance.

Contents

This section includes the following topics:

7.1 Troubleshooting 73

7.2 Event log management 76

7.3 INFOevents 80

7.4 ERRORevents (control unit) 82

7.5 ERRORevents (sensor) 84

7.6 ERRORevents (CANbus) 85

7.7 Cleaning and spare parts 85

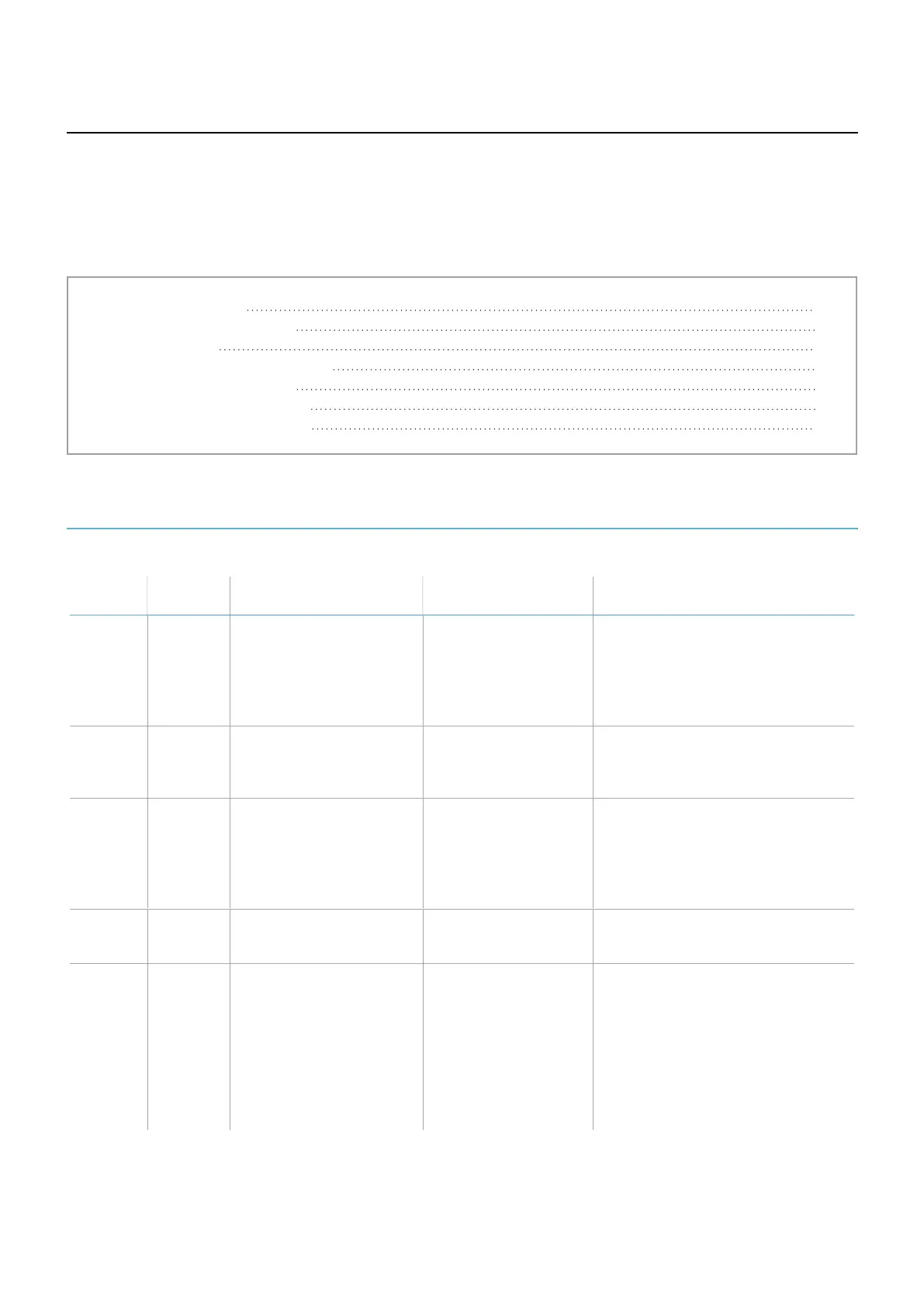

7.1 Troubleshooting

7.1.1 Control unit LED

LED Status

Inxpect Safety

application messages

Problem Remedy

S1* Steady red CONTROL UNIT

POWERERROR

At least one voltage

value on the control

unit is wrong

If at least one digital input is

connected, check that the SNS input

and the GND input are connected.

Check that the input power supply is

the specified type (see "General

specifications" on page87).

S2 Steady red CONTROL UNIT

TEMPERATUREERROR

Control unit

temperature value is

wrong

Check that the system is operating

at the correct operating

temperature (see "General

specifications" on page87).

S3 Steady red OSSD ERROR or INPUT

REDUNDANCY ERROR

At least one input or

output is in error

If at least one input is used, check

that both the channels are

connected and that there is no short

circuit on the outputs.

If the problem persists, contact

assistance for output replacement.

S4 Steady red PERIPHERAL ERROR At least one of the

control unit peripherals

is in error

Check the status of the terminal

block and connections.

S5 Steady red CANERROR Communication error

with at least one

sensor

Check connections of all sensors in

the chain starting from the last

sensor in error.

Check that all the sensors have an

assigned ID (in Inxpect Safety

Settings > Node IDAssignment).

Check that the firmware of the

control unit and sensors are

updated to the compatible versions.

LBK System Series| Instruction manual v1.2 SET 2021|SAF-UM-LBKBus-en-v1.2|© 2020-2021 Inxpect SpA

73

Loading...

Loading...