6

2. INSTALLATION

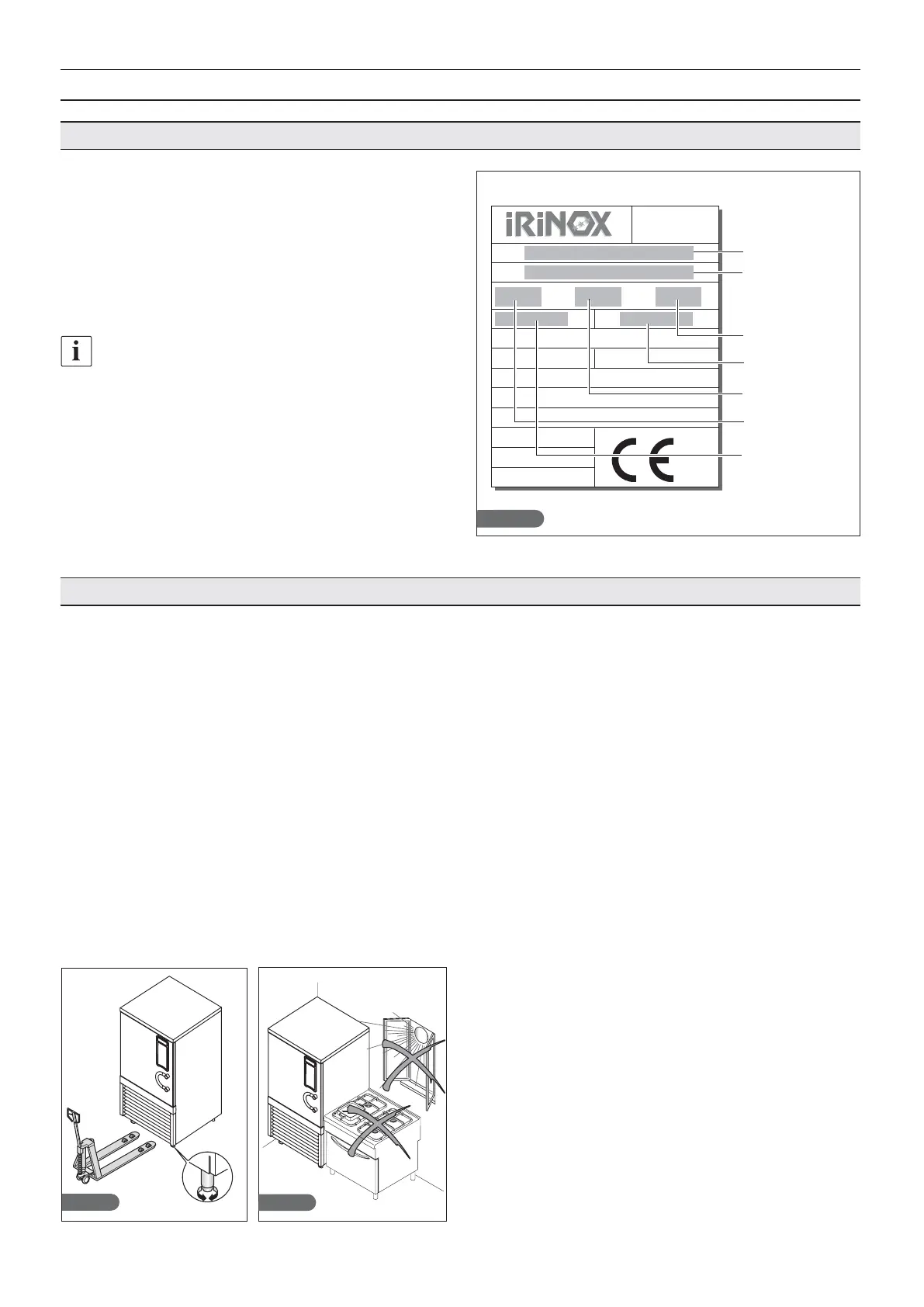

2.1. PLATE DATA

•

•

•

Make sure that the plate data and electrical line

features correspond (V, kW, Hz, phase and available

power).

The plate carrying the features of the appliance is

applied on the side (fig.2).

Preparation of machine rooms to dislocate the condensing

units must comply with the fire-prevention Standards in

force in the Country where the machine is installed (contact

the nearest fire station for due indications).

Remember also that the potential intervention of

safety valves or fuse caps in the refrigeration circuit

entails the immediate discharge of all the refrigerant

used in the ambient. Therefore make sure to realise

opportune means of waste disposal and first aide, as

indicated on the safety cards of the refrigerant

(

8see

par. 2.12).

Climatic class:

4 (30°Croomtemperaturewith55%non-condensing

relative humidity) according to Standards CEI EN

60335-1, CEI EN 60335-2-89, ISO 23953-2:2005(E)

Fig. 2

31020

CORBANESE (TV)

ITALY

Mod.

s/n

Compressor HERMETIC

V

A

Refrigerant R404 Charge

Desing pressure (Low)

Desing pressure (High)

Rated Load

Class Volume

PED Code

IP

KPa

KPa

Kw

Ph Hz

Model

Series n.

mm/yy/progres.

Frequency

Power

Phase

Absorption

Voltage

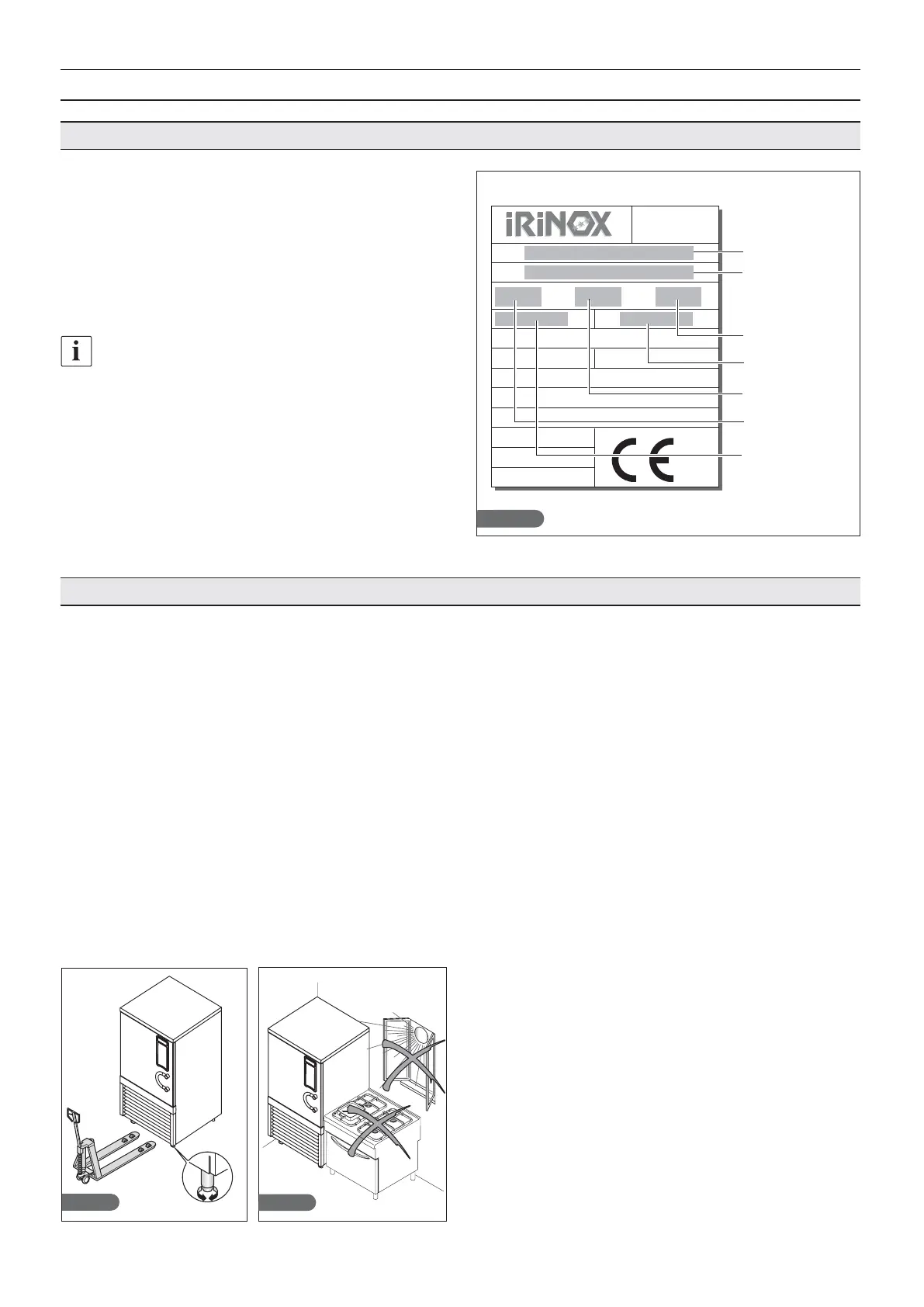

2.2. POSITIONING

The blast chiller must be installed and inspected in

complete compliance with accident-prevention Law

Standards, with traditional rules and with Standards

now in force.

The installer must check potential fire-prevention

prescriptions (contact the nearest fire station for the

due indications).

Place the blast chiller in the intended spot.

Level the appliance by means of the adjustment feet.

Use appropriate lifts to level heavier machinery (Fig.3).

If the appliances are not levelled, their operation and

condensation outflow can be jeopardised.

To be avoided (Fig.4):

Places exposed to direct sunlight

Closed places with high temperatures and scarce air

exchange (

8see Table 2).

Do not install the machine near to any heat sources.

•

••

•

•

•

•

•

•

•

•

•

Fig. 4

Fig. 3

The remote units are manufactured to be installed in

places protected against adverse weather conditions.

The plants must be positioned on a levelled cement

or steel base and must have the maintenance space

according to the technical files. If installed on the roof

or attic, beams should be provided which divide the

weight. Furthermore the base must be sufficiently

sturdy and capable of bearing the weight of the com-

plete unit resulting from the technical data of the

specific drawing. To avoid further vibrations or noise,

it is recommended to use neoprene anti-vibration

pads underneath the corners of the unit's base.

If the blast chiller/conserver is installed below floor

level or underground, the installer must apply the

clauses foreseen by the standard EN378-

1:2008+A1:2010 ANNEX D to guarantee that no one

can remain locked inside the cell at the end of the

work shift.

The blast chiller/conserver can be installed under-

ground or on a loft as long as there are adequate

emergency exits as foreseen by the standard EN378-

1:2008+A1:2010 ANNEX C.

The installer must verify the need for forced ventila-

tion inside a room where the blast chiller/conserver is

installed as foreseen by the standard EN378-

2:2008+A1:2009 chapter 6.2.14.

Loading...

Loading...