32

4.4. TROUBLESHOOTING

Electronically-managed diagnostics:

• This symbol turns on

• The alarm Code appears on the DS1 display

DescriptionCode

AL0

Downloading

default data

AL1

Serial line error

for printing

Incorrect cable connection

Faulty electronics Replace the circuit board

Connect the serial cable of the

printer correctly

AL2

Depleted clock module

or battery:

registration block

Depleted clock module or battery:

registration block

Replace circuit board

AL3

ALP

Cell temperature

at 40°C during

defrost cycle

High pressure alarm

Cell door micro

switch faulty

High work room temperature

Check that the "open door" indicator

signals opening and closing correctly.

If not: intervention of a technician

to replace micro switch.

Air condition the work room

High room temperature

(above 32°C)

Dirty condenser filter Clean the condenser

Condenser fan faulty Intervention of a technician

The starting condenser of the

condenser fan is faulty

Intervention of a technician

Intervention of a technician

Condensation control pressure

switch faulty (only for versions with

remote unit or remote condenser)

High pressure pressure switch faulty

Intervention of a technician

Excessive gas load in system

Open compressor discharge tap

Compressor discharge tap closed

Intervention of a technician

Possible cause Possible solution

The electronic control of the machinery is equipped with a

visual system which signals the presence of alarms.

The alarms are registered on an alarm list.

In case of alarms:

Press P1

Eliminate the cause of the alarm

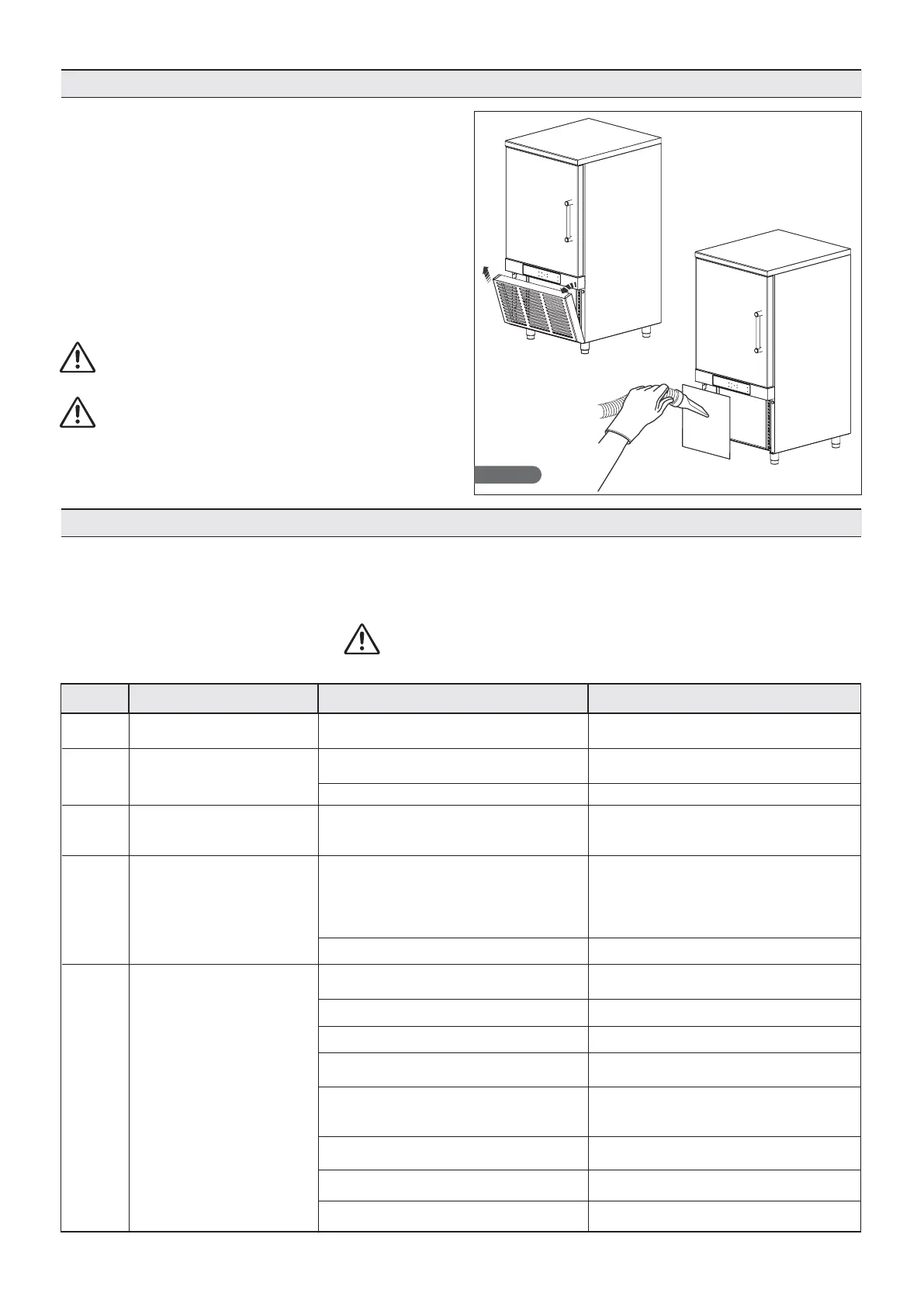

4.3. CLEANING THE CONDENSER

For Blast chillers with built-in condensing units, access

the condenser pulling the front flapped grid with force.

For remote condensing units, the air condenser must

be kept clean to allow free air flow.

This operation, which must be carried out at least every 30

days, can be done with non-metallic brushes in order to

remove all dust and down from the condenser flaps. It is

recommended to use a vacuum cleaner to avoid disper-

sing the dust in the area. Use a brush soaked in alcohol if

there are oily deposits.

Do not scrape the surfaces with sharp or abrasive

elements.

Always wear protective gloves, goggles and masks

protecting the respiratory tract for these operations.

Fig. 18

Loading...

Loading...