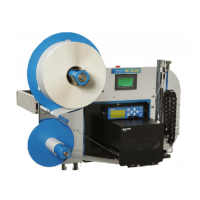

Diagraph - an ITW Company PA/4600 & PA/6000 User Manual

Troubleshooting Page 39

Troubleshooting

TAMP ISSUES

Problem Cause Correction

Label is on the tamp pad, but

tampcylinderdoesnotfire

Product detector not triggered

byproduct

Verif yin Diagnostics Menu that

the product detector can

repeatedly detect the product.

Adjustsensorasnecessary

Apply trigger occurred before

labelwasontamppad

Increase distance of product

detectorfromtamppad toallow

feedingtocomplete

CylinderHomeSensordoesnot

sensetheretractedtamppad

Checkthesensorforpositionon

the cylinder and wire

termination at the interface

board. Verify air pressure is

present and the OSHA shutoff

valveisopen.

Label present is installed and

enabled,butthesensordoesnot

seethelabel

Check that the sensor is

operationalby placinganobject

infrontofthesensor.Verifythat

the yellow light is illuminated

on the sensor. Try adjusting the

sensor away from the tamp pad

surface and re‐check label

presence.

Checkthatthesensor’s signalis

detectedat

theMCAbyentering

DiagnosticsandviewtheSensor

screen. Cover and uncover the

sensor and verify the

Diagnostics screen shows the

same(see

page 31).

Tamp padis contactingproduct

withtoomuchforce

Auto Retract is installed and

Auto Retract Time is set too

long

Decrease the Auto Retract Time

to minimize the tamp pad

contact time with the product

surface(see

page 29).

AutoRetractisnotinstalledand

TampDurationistoolong

Decrease the Tamp Duration

Time to minimize the tamp pad

contact time with the product

surface(see

page 28).

Cylinder retract flow control is

constricted,andtheextendflow

controlisfreeflowing

Increase the retraction flow to

allow the cylinder to move as

fast or faster than the extension

speed(see

page 20).

Loading...

Loading...