45

ATTENTION:Do not change the rotation while checking the nozzles flow rate. Change on the

rotation will change the pressure on the nozzles and hence their flow rates.

OPERATION AND ADJUSTMENTS

To calibrate every boom section, proceed as follows:

01-Run the sprayer and turn on the chemical flow to all boom sections.

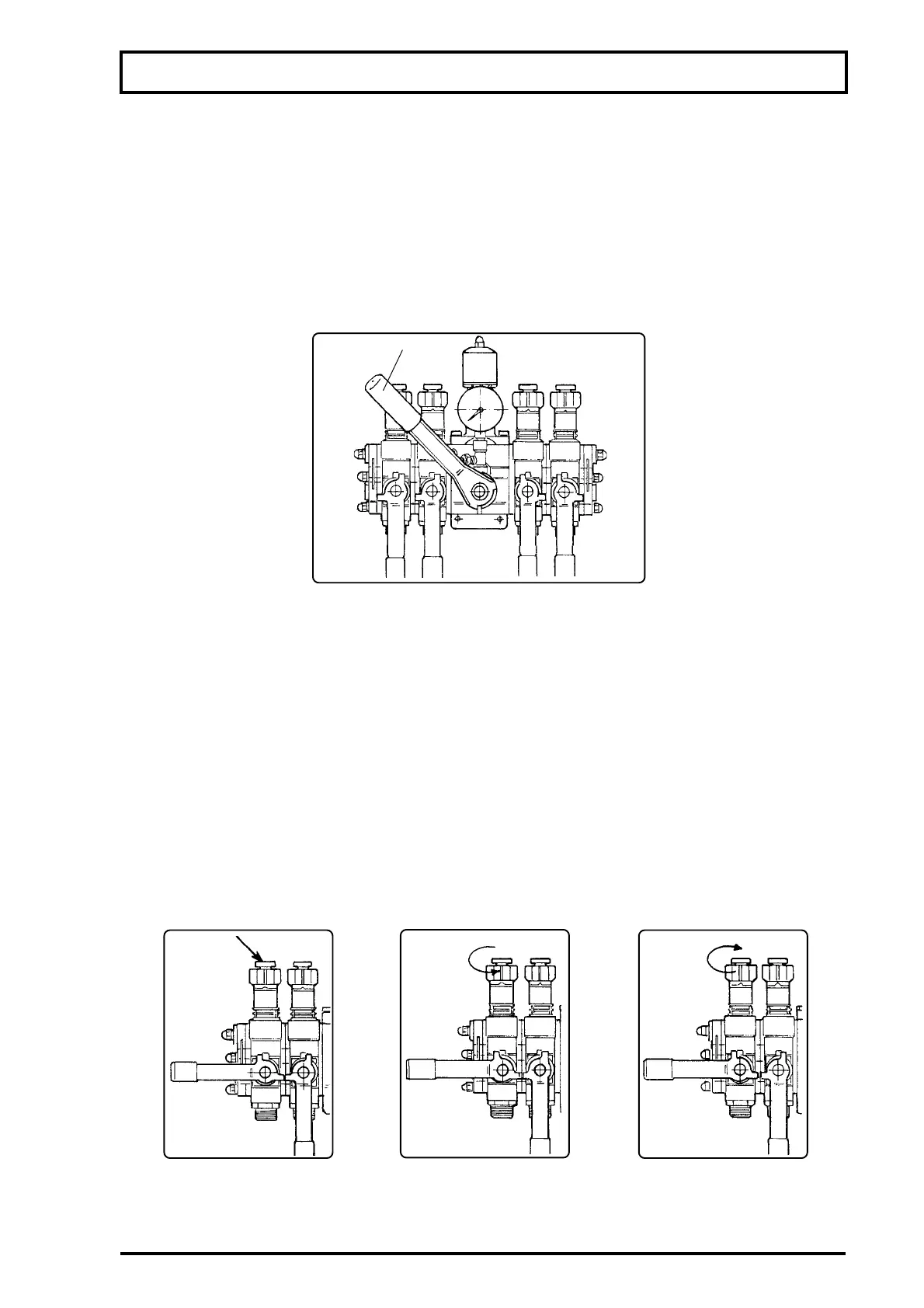

02-Set the relief lever (1) in the position P [pressure].

03-Set the levers (2), (3), (4) and (5) to point down.

04-Check the pressure indicated by the pressure gauge.

05-Choose one of the boom sections and set the lever aside all the way [to turn off].

06-Other levers should remain pointing down [to turn on].

07-Check if the pressure indicated by the pressure gauge changed. If so, proceed as follows:

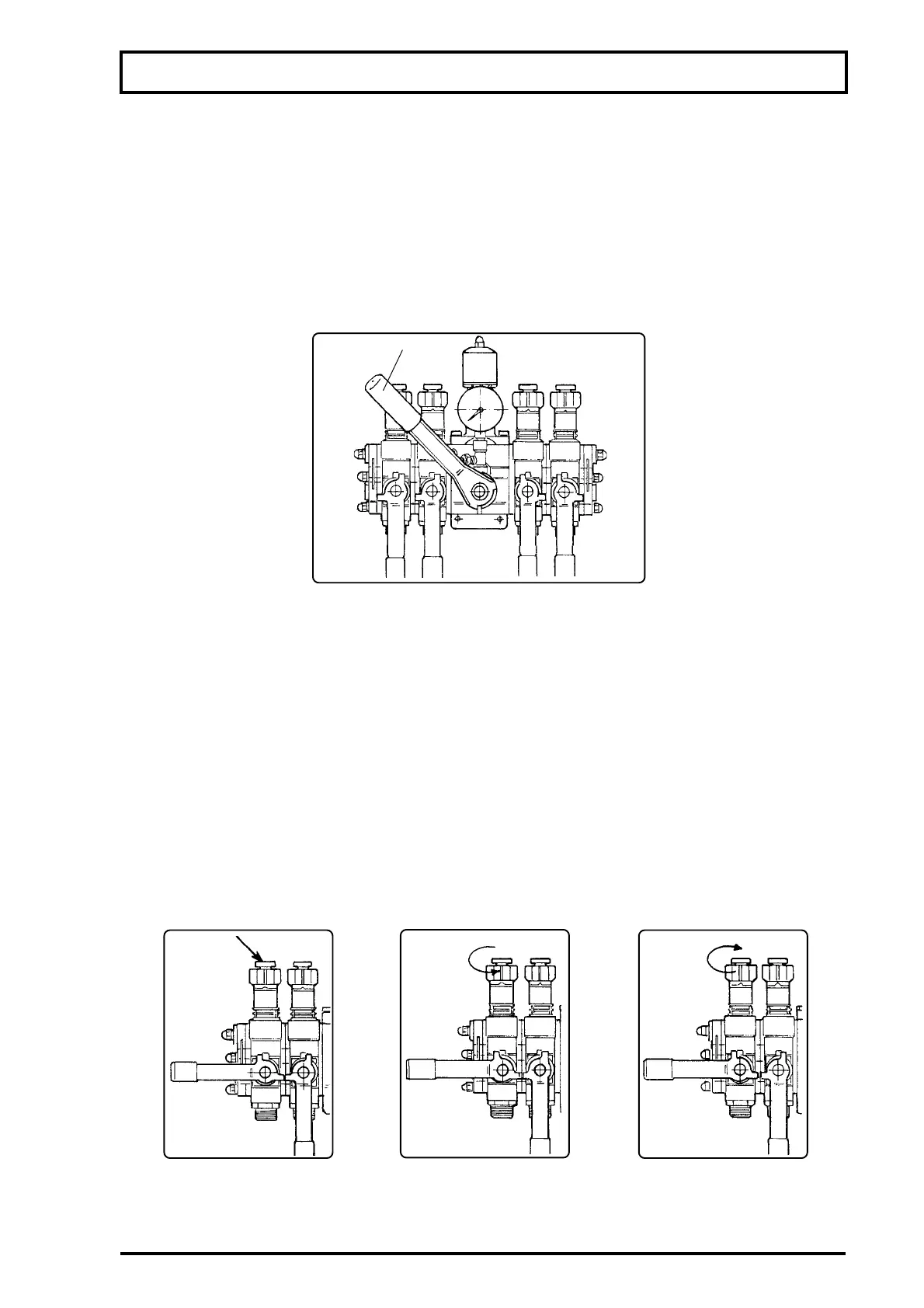

-Loosen the fastening screw shown by the arrow (figure E).

-Turn the knob clockwise to increase the operating pressure (figure F).

-Turn the knob counterclockwise to decrease the operating pressure (figure G).

NOTE:The pressure should be equal to that previously indicated by the pressure gauge when

the nozzles of this boom section were turned on.

-After calibrating the pressure gauge, set the lever back in the position "PULVERIZAR"

[SPRAY] (to point down/turn on).

-Do the same on every boom sections in order to maintain constant pressure along the entire

boom, regardless of the number of boom sections turned on.

(P)

23

1

D

54

EGF

Loading...

Loading...