Page 9

ENGLISH

Jandy

®

Pro Series VS PlusHP Pumps

|

Installation & Operation Manual

CAUTION

Failuretoprovidedataplatevoltage(within10%)during

operation will cause the motor to overheat and void

the warranty.

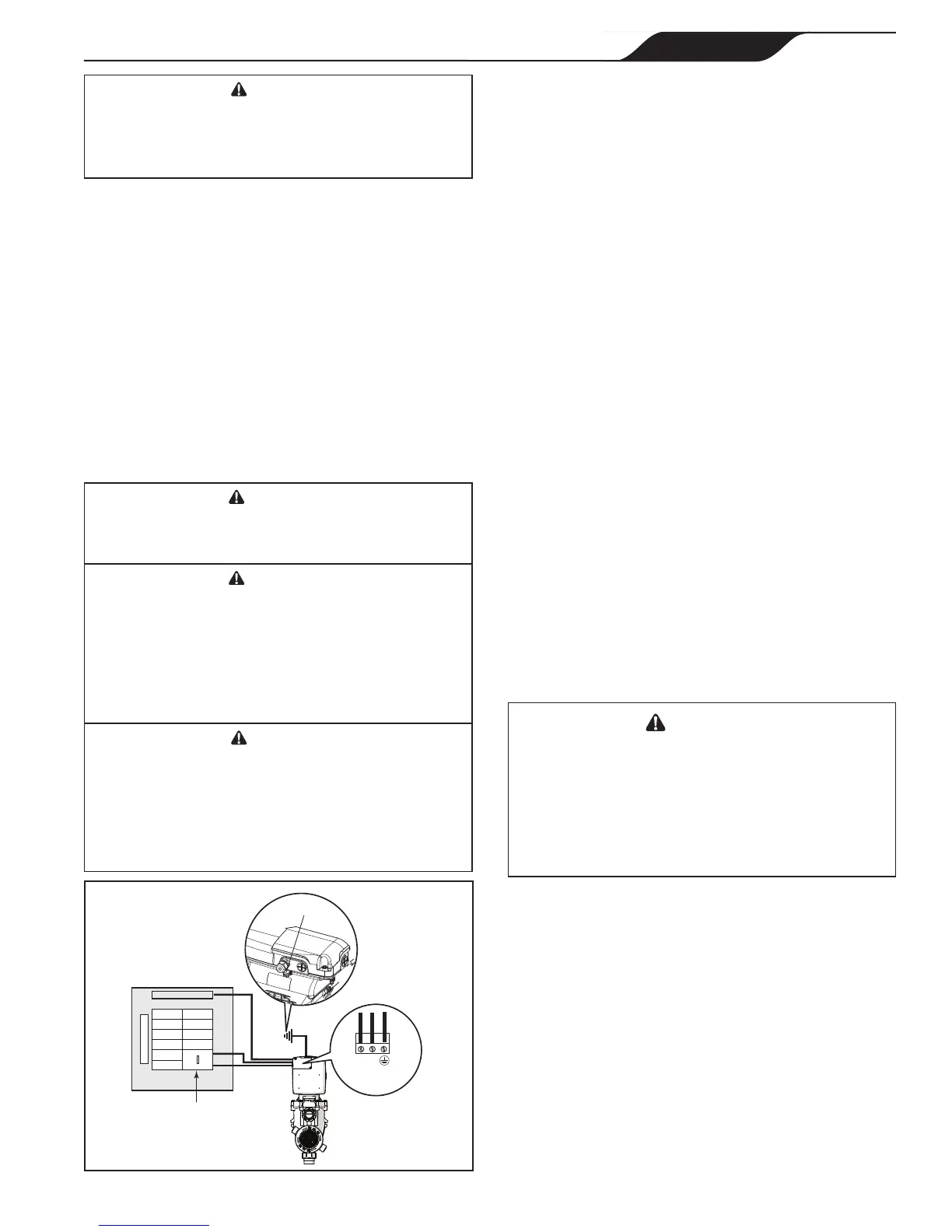

3.2.2 Bonding and Grounding

1. In addition to being properly grounded and in

accordance with the requirements of the National

Electrical Code (NEC), or in Canada the Canadian

Electrical Code (CEC), the pump motor must

be bonded to all metal parts of the swimming

pool, spa or hot tub structure and to all electrical

components and equipment associated with the

pool/spa water circulation system.

2. The bonding must be accomplished by using a

solid copper conductor, No. 8 AWG or larger. In

Canada No. 6 AWG or larger must be used. Bond

the motor using the external bonding lug provided

on the motor frame.

WARNING

Always disconnect the power source before working

on a motor or its connected load.

WARNING

Make sure that the control switch, time clock, or control

system is installed in an accessible location, so that in

theeventofanequipmentfailureoralooseplumbing

fitting,theequipmentcanbeturnedoff.Thislocation

must not be in the same area as the pool pump, filter,

andotherequipment.

CAUTION

The pump must be permanently connected to a

dedicatedelectricalcircuit.Nootherequipment,

lights, appliances, or outlets may be connected to the

pump circuit, with the exception of devices that may

berequiredtooperatesimultaneouslywiththepump,

such as a chlorinating device or heater.

GROUND

NEUTRAL

Breaker Panel

GFCI

Pump

L1

L2

Terminal Block

Figure 4. Bonding the Motor

3.2.3 Electrical Wiring

1. The pump motor must be securely and adequately

grounded using the green screw provided. Ground

before attempting to connect to an electrical power

supply. Do not ground to a gas supply line.

2. Wire size must be adequate to minimize a voltage

drop during the start-up and operation of the pump.

3. Insulate all connections carefully to prevent

grounding or short-circuits. Sharp edges on

terminals require extra protection. For safety,

and to prevent entry of contaminants, reinstall all

conduit and terminal box covers. Do not force

connections into the conduit box.

3.2.4 Controller Options

The pump can be operated by one (1) of four (4)

controllers,

JEP-R variable-speed controller, AquaLink RS,

AquaLink PDA or AquaLink Z4.

The pump communicates with the controllers via a four-

wire RS-485 interface.

NOTE Since the pump is operated by an external

controller the pump will not be turned on until it

is turned on with a controller.

3.2.4.1 Install with AquaLink

®

controller

The VS PlusHP pump can be operated by the following

AquaLink Controllers:

• AquaLink RS (Rev O or later)

• AquaLink PDA (Rev 4.0 or later)

• AquaLink Z4

1. Disconnect the high voltage lines or open any

breaker to which the pump power is connected.

WARNING

ELECTRICAL SHOCK HAZARD

Turn off all switches and the main breaker in

the variable-speed pump electrical circuit before

starting the procedure. Failure to comply may

cause a shock hazard resulting in severe personal

injury or death.

2. Dip switches 1 and 2 need to be in the OFF

position. See “Figure 5. Wiring AquaLink RS,

PDA or Z4”.

3. Select the desired address(es) by setting dip

switches 3 and/or 4, as shown in “Table 2. Dip

Switch Settings”

4. Disconnect the RS-485 cable from the 4-pin

header on the pump drive.

NOTE: Do not cut the cable or you will lose the ability to

returntothedefaultfactoryconguration

5. Connect the new RS-485 cable from the AquaLink

through the available compression tting and

route the 4-conductor cable through the motor

drive threaded port closest to the connector. See

““Figure 5. Wiring AquaLink RS, PDA or Z4”

Loading...

Loading...