Page 14

ENGLISH

Jandy

®

Variable-Speed Pumps

|

Installation & Operation Manual

3.5.2 Dip Switch Settings with Automation

Dip Switch 3-4 setting rules are not common across

all Jandy automation systems. Please reference the

following sections to understand the required settings.

For Jandy Aqualink RS Automation System users, a

2022 mid-year update changes the method in which

pumps in this manual interact with Jandy Aqualink RS

systems. Refer to the RS manual for more information.

3.5.3 Pre-2022 Aqualink RS Firmware Rev_V

and Earlier

Aqualink RS systems using rmware Rev V and earlier,

manufactured prior to mid-year 2022, support up to 4

variable-speed pumps. Each pump is assigned an address

of 1 through 4 using Dip Switches 3-4 on the pump. Use

the table below for pump address assignment settings.

These settings are used when connected to the RS485

connection on the pump or when connected to the pump

using a SpeedSet controller’s automation pass-through

wiring connection on the bottom of the controller.

Address Switch 3 Switch 4

Pump 1 OFF OFF

Pump 2 ON OFF

Pump 3 OFF ON

Pump 4 ON ON

Table 4. Local Controller DIP Switch Settings

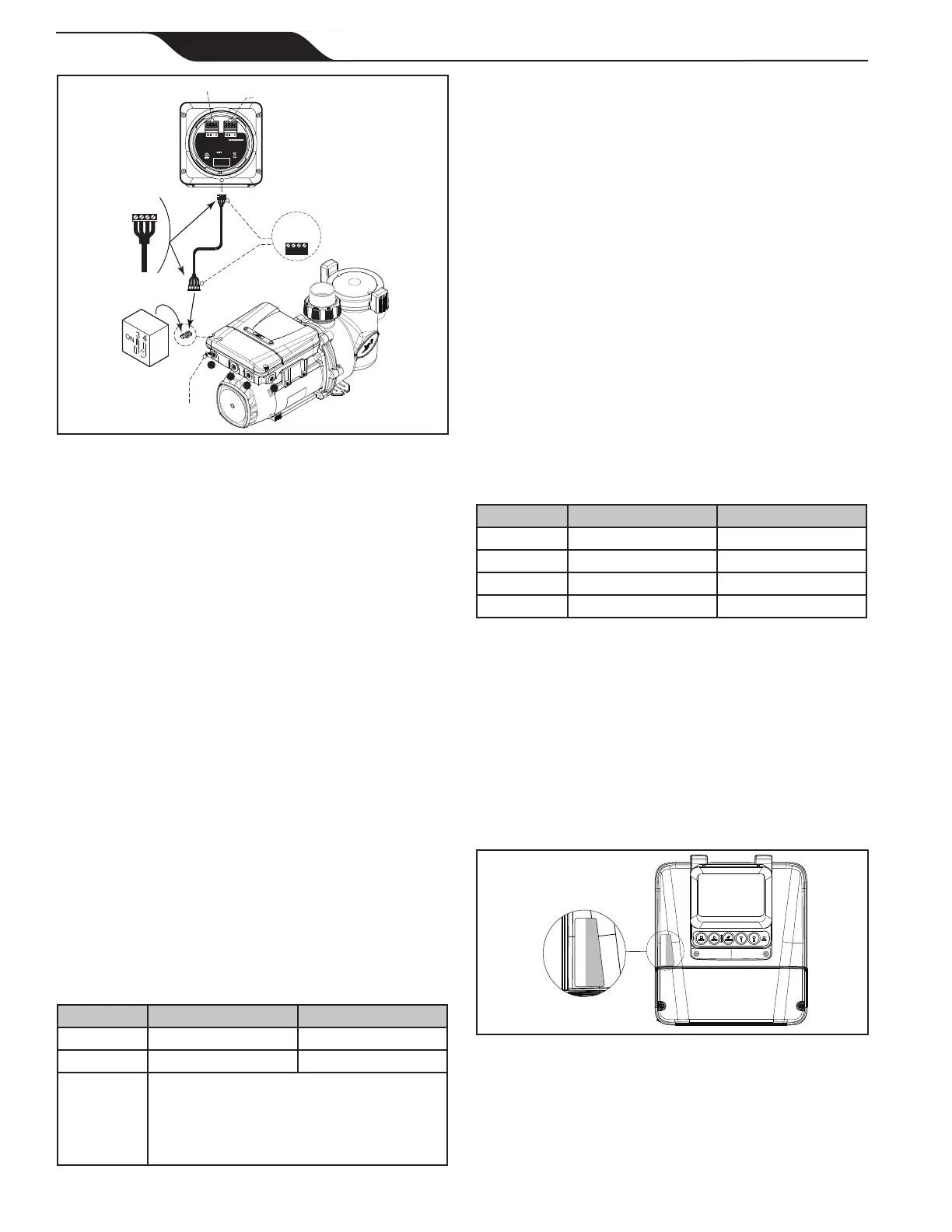

3.5.4 2022 Aqualink RS Firmware Rev W

and Later

Aqualink RS systems using Rev W and later,

manufactured after mid-year 2022, support up to 16

variable-speed pumps that utilize a pre-assigned PUMP

ADDRESS. Dip Switches 3-4 are not utilized. Pumps in

this manual are all assigned a unique PUMP ADDRESS

at the factory. The PUMP ADDRESS label can be found

on the pump motor in the location shown below.

PUMP ADDRESS

Figure 10. Pump Address Label Location

When setting up pumps using this method, the pump

address of each pump will initially appear in the

unassigned pump address section of the iAqualink App

or other automation setup device. Utilize the App or

other device to complete pump setup.

1- 3/8” Threaded

2- 3/4” Threadless

3- 1/2” Threadless

1

2

3

4

2-Position

DIP Switch

Bonding

Lug

RS485

4321

Speedset

Controller

(Bottom View)

BLACK

YELLOW

RED

GREEN

RS485

Cable (22 AWG)

4321

BLACK

YELLOW

RED

GREEN

H0738200_REVB

Conforms to ANSI/UL Std. 1563 Certified to CAN/CSA Std. C22.2 No. 218.1

FOR INDOOR/OUTDOOR USE

POUR USAGE INTÉRIEUR/EXTÉRIEUR

PARA USO INTERIOR/EXTERIOR

10V 200mA

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation. CAN ICES-003 (B) / NMB-003 (B)

RECOGNIZED

COMPONENT

3032401

Zodiac Pool Systems LLC

Model # SpeedSet

CAUTION/ATTENTION

READ THE INSTRUCTION MANUAL

LIRE LA NOTICE TECHNIQUE

TO AUTOMATION TO PUMP

To Automation

To Pump

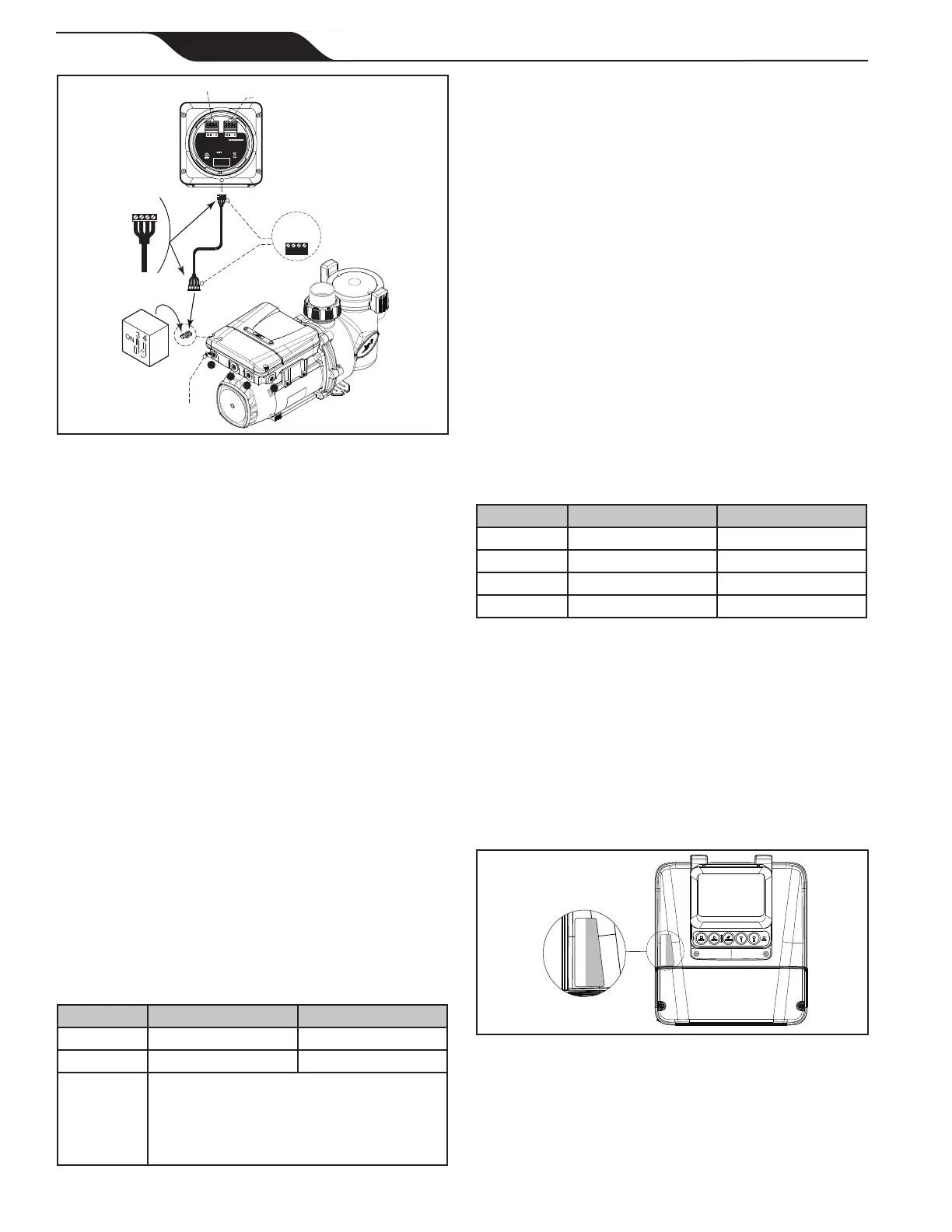

Figure 9. Wiring to a Controller

3.4 Pump Controller / Automation

System Setup

Pumps in this manual are compatible with the following

local Jandy controllers and automation systems:

• SpeedSet Controller (local)

• iQPUMP01 (local)

• JEP-R (local)

• All Jandy Automation Systems

Each motor is equipped with an auto-sensing power

circuit which automatically determines if 10v of power

should be supplied to the RS485 wiring in order to

power a local controller interface, or to suppress the 10v

power supply when connected to a Jandy Automation

system.

This auto sensing power circuit eliminates the need for

Dip Switches 1-2 that are present on other Jandy Pumps.

3.5 Dipswitch Settings

3.5.1 Dipswitch Settings with Local

Controller

Please refer to the following table for required settings

for Dip switches 3-4 when the pump is connected to a

local controller.

Controller Switch 3 Switch 4

JEP-R OFF OFF

iQPUMP01 OFF OFF

SpeedSet

Dip Switch 3-4 settings are only important

when connected to a Jandy automation

system using SpeedSet automation pass-

through wiring connection on the bottom of

the controller.

If applicable, please see following sections.

Table 3. Local Controller DIP Switch Settings

Loading...

Loading...