6 - 1

Throttle Motor and Throttle Link

Replacement

1. Prepare the machine

Position the machine on level ground.

Stop the engine and remove the starter key.

2. Locate the throttle motor and link

See Component Location Diagram in Routine

Maintenance.

Note: Upon delivery of the Throttle motor the position of the

output axis shaft is in a random position, so it needs

adjusting.

3. Throttle motor replacement

Connect the wiring of the Throttle motor and switch it to

the redundancy position.

Position the motor so that the output shaft is rotated

counter clockwise.

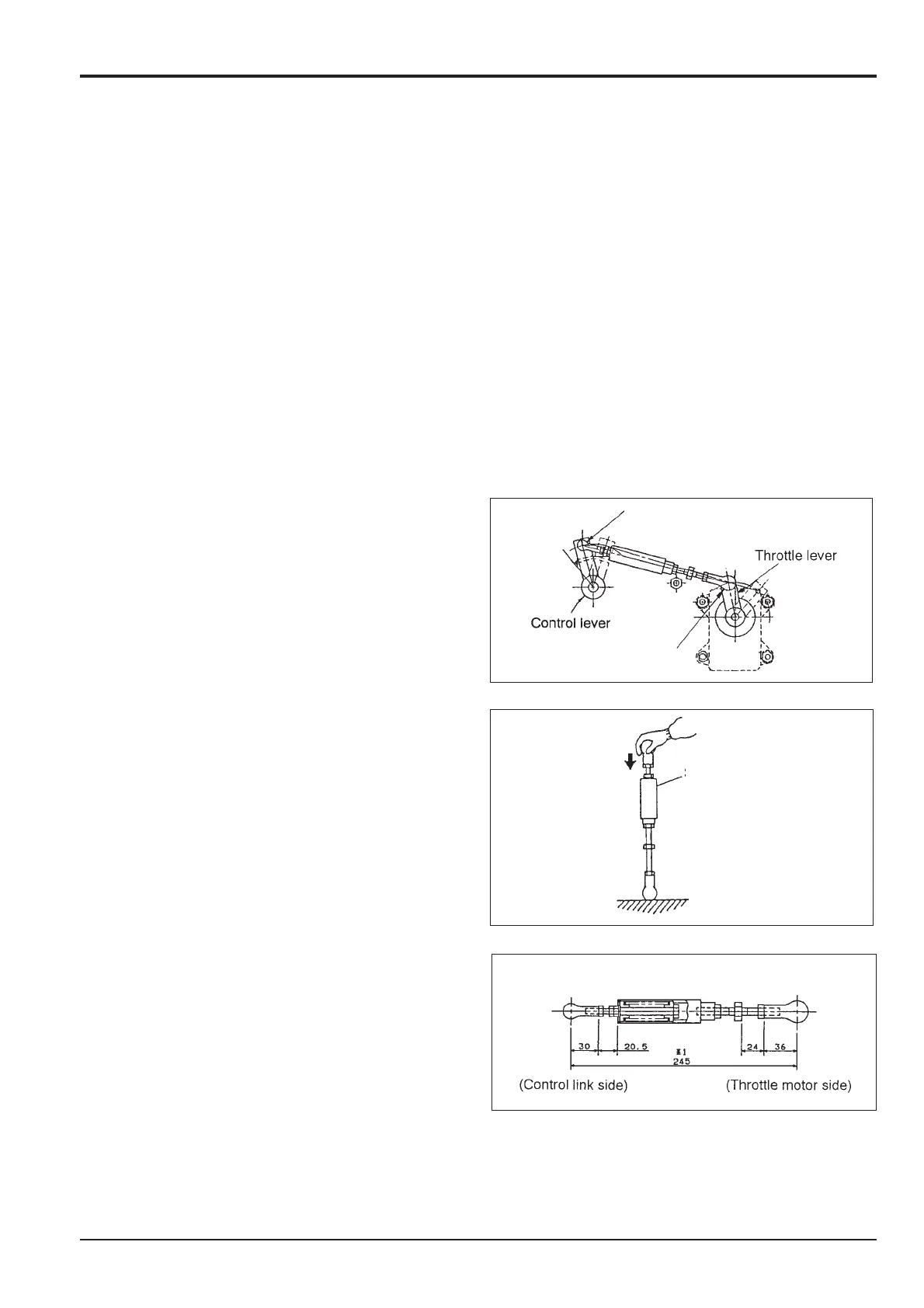

4. Removal of Throttle Link

Remove the nuts of the throttle link at the control lever A,

then remove the nuts on the opposite end of the throttle

link at the throttle lever end B. Then remove the link

without disassembly.

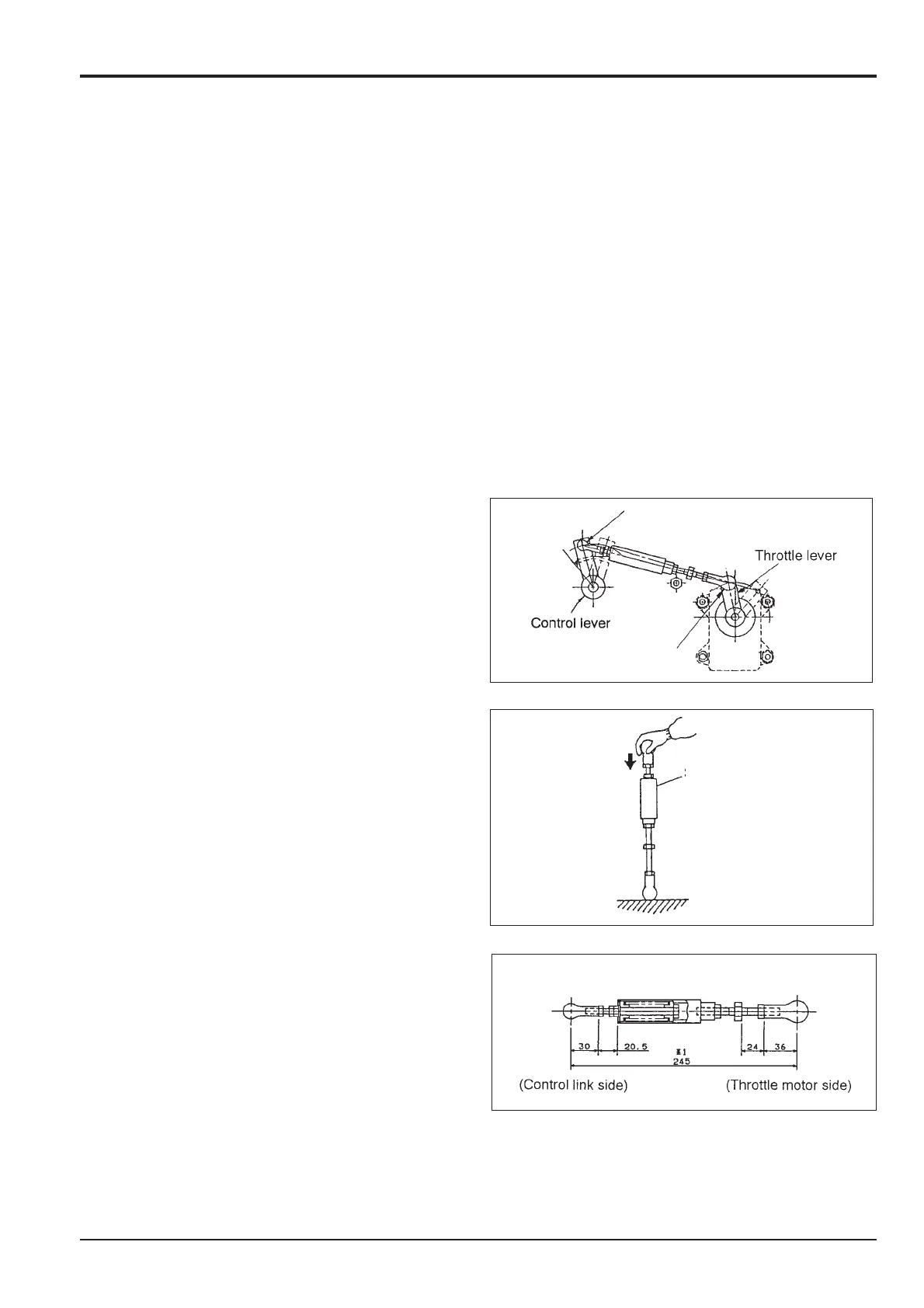

5. Checking operation of Throttle Link

a. Confirm whether the Spring chamber C of the link

operates normally before installing the throttle motor.

b. Stand the link and press on it from the top, and

confirm that the spring has compressed

(approx 20 mm).

c. If using the throttle link when the spring does not

compress because of its internal corrosion, the motor

will be damaged.

d. If the spring does not compress, replace it.

6. Disassembly of throttle link

a. While it is possible to disassemble the link it is

advisable to replace the unit with a new one.

b. If it is disassembled, reassemble the unit to the

dimensions shown opposite.

Note: The overall dimensions shown are not fixed as each

installation may vary.

Section C

Electrics

9803/6400

Section C

6 -1

Issue 1

Throttle Motor

A

B

C

Loading...

Loading...