32 - 2

Section E

Hydraulics

9803/6400

Section E

32 - 2

Issue 1

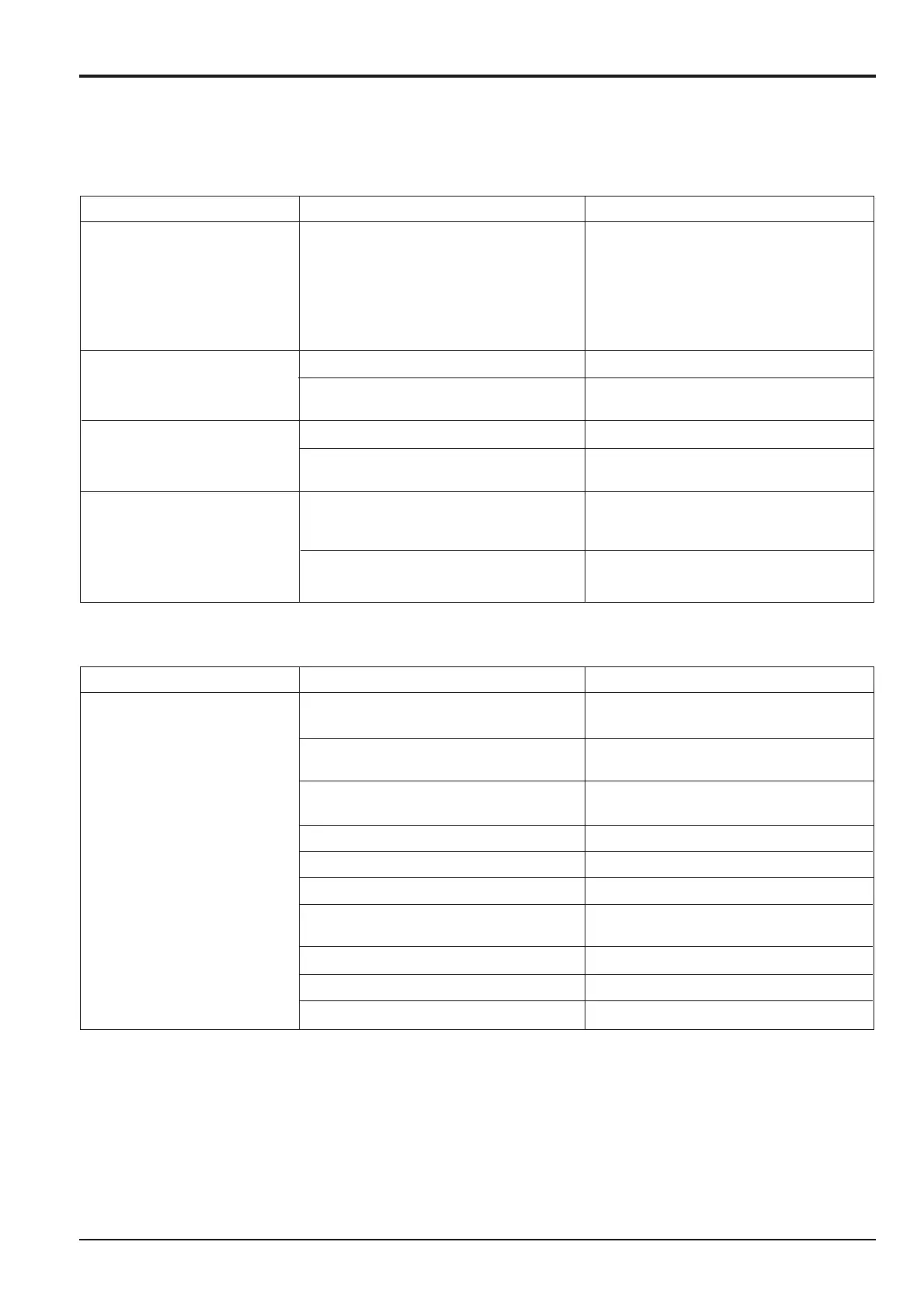

Control Valve JS200/JS240

Control Valve Trouble Shooting (continued)

Relief Valve

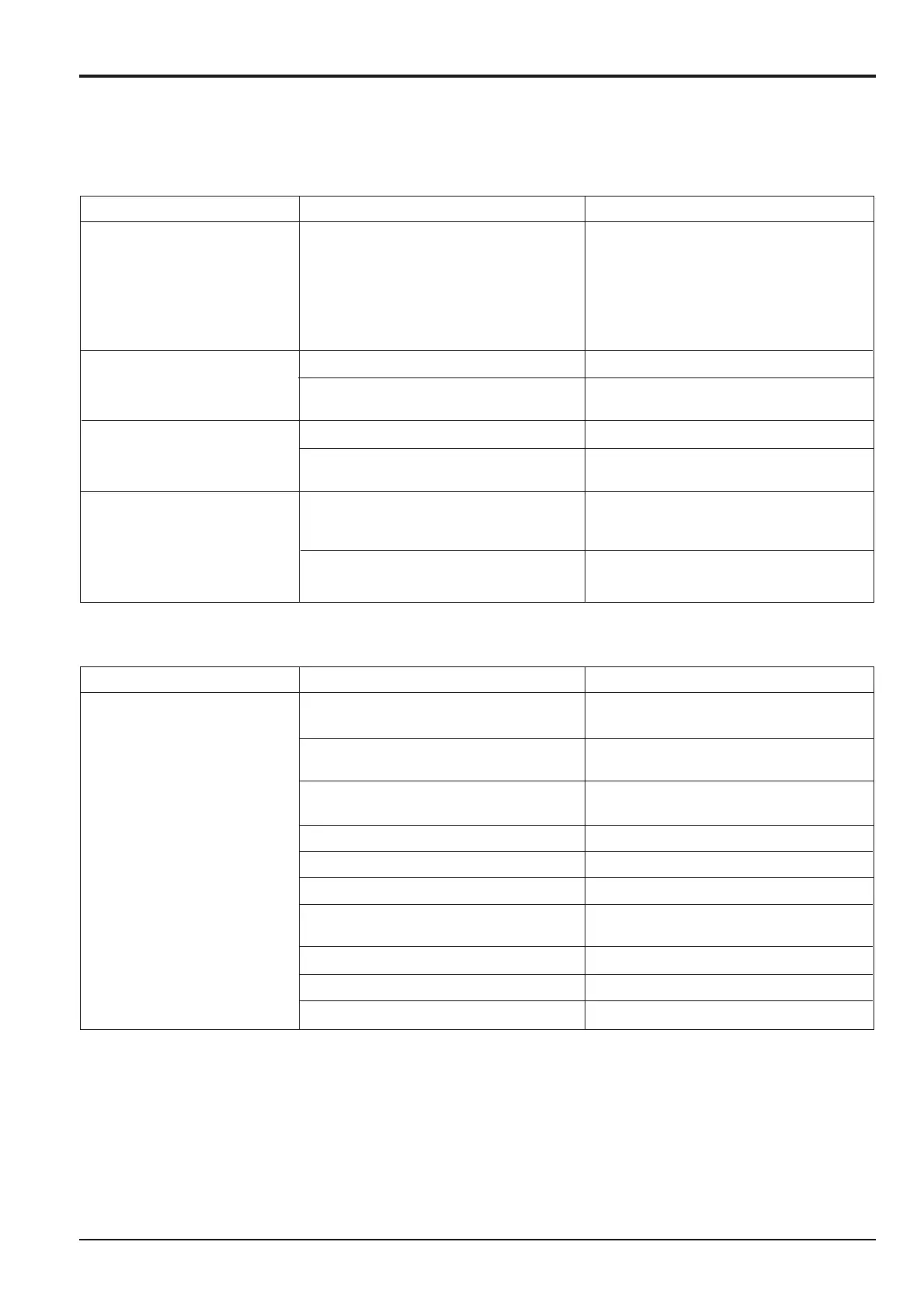

Hydraulic System

Symptoms Possible Causes Countermeasures

Pressure does not rise at all 1. The main poppet, sleeve or pilot Check whether foreign matter is in each

poppets are sticking open or poppet.

foreign matter is in the valve seat.

Check whether each part is sliding

smoothly.

Clean all the parts.

Relief pressure is unstable 1. The pilot poppet seat is damaged. Replace the damaged parts.

2. The piston is sticking to the main poppet. Remove the surface scratches.

Clean all the parts.

Relief pressure is out of control 1. Wear due to foreign matter. Replace the worn parts

2. Lock nut and adjuster are loose. Reset the pressure and tighten the lock nut

to the rated torque.

Oil leakage 1. Damaged seat or worn O-ring. Replace damaged or worn parts.

Check whether each part is sliding

smoothly.

2. Parts are sticking due to foreign Check for scratches, cuts or foreign matter.

matter. Clean all the parts.

Symptoms Possible Causes Countermeasures

The hydraulic system is not 1. Pump problem. Check the pressure or replace the pump.

working well or not at all

2. Foreign matter clogging inside the Disassemble the relief valve and clean.

relief valve.

3. Relief valve trouble. Check according to the maintenance

procedures.

4. Ram trouble. Repair or replace.

5. Load is too heavy. Check the circuit pressure.

6. Crack in the valve. Replace the valve assembly.

7. Spool does not stroke fully. Check the spool movement and

operation link.

8. Oil level too low. Replenish hydraulic oil.

9. Filters inside circuit are clogged. Clean filter or replace.

10. Hose runs are kinked. Check the hoses.

Loading...

Loading...