Reconditioning (continued)

Jig Usage (continued)

76 - 7

Section E

Hydraulics

9803/6400

Section E

76 - 7

Issue 2*

Hydraulic Rams

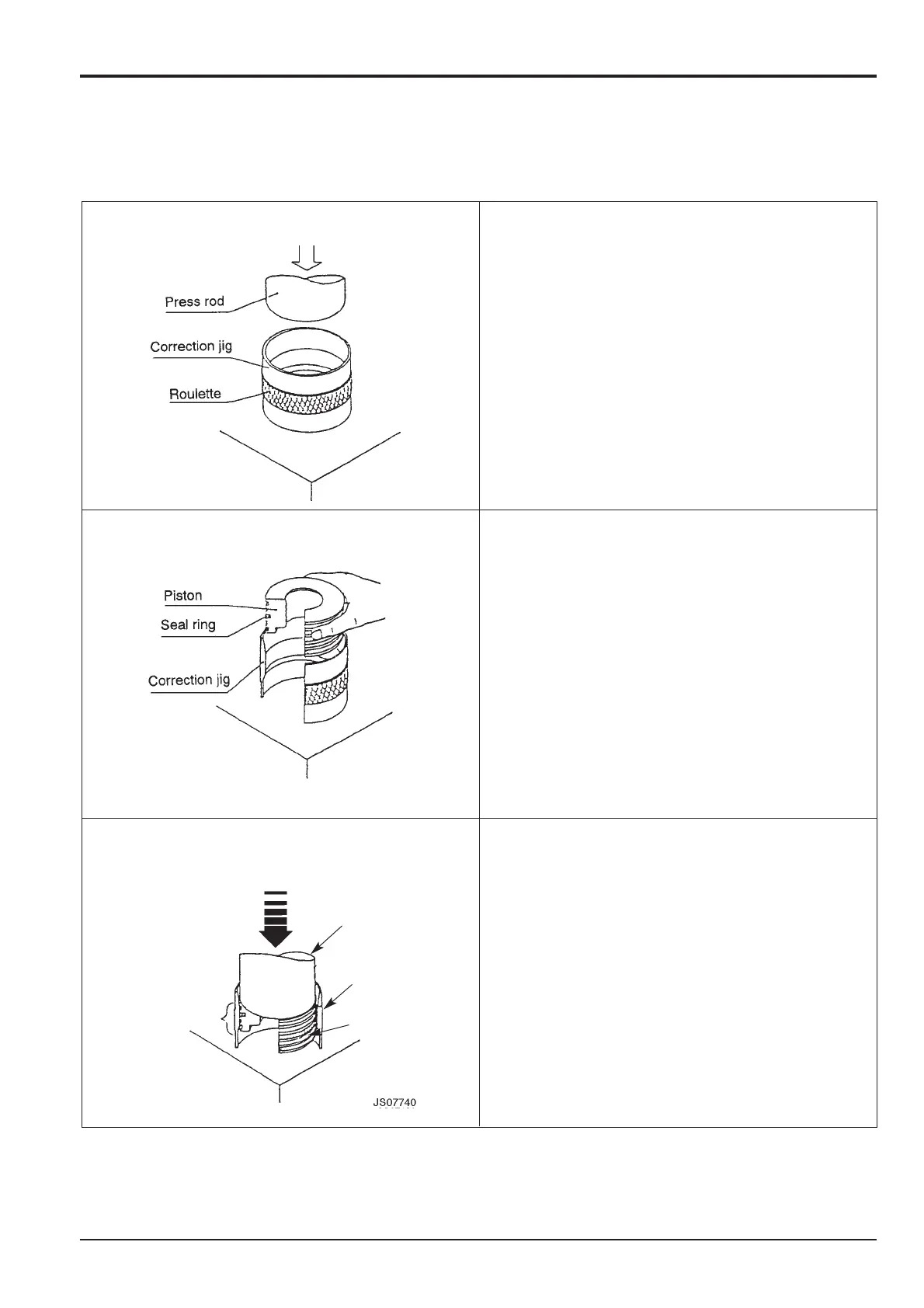

Set the correction jig underneath the press.

Apply a thin coat of lubricant to the tapered section of the

correction jig and place the jig with the tapered section

facing up.

Be careful that no dust, chipped metal and lint adheres to

the jig.

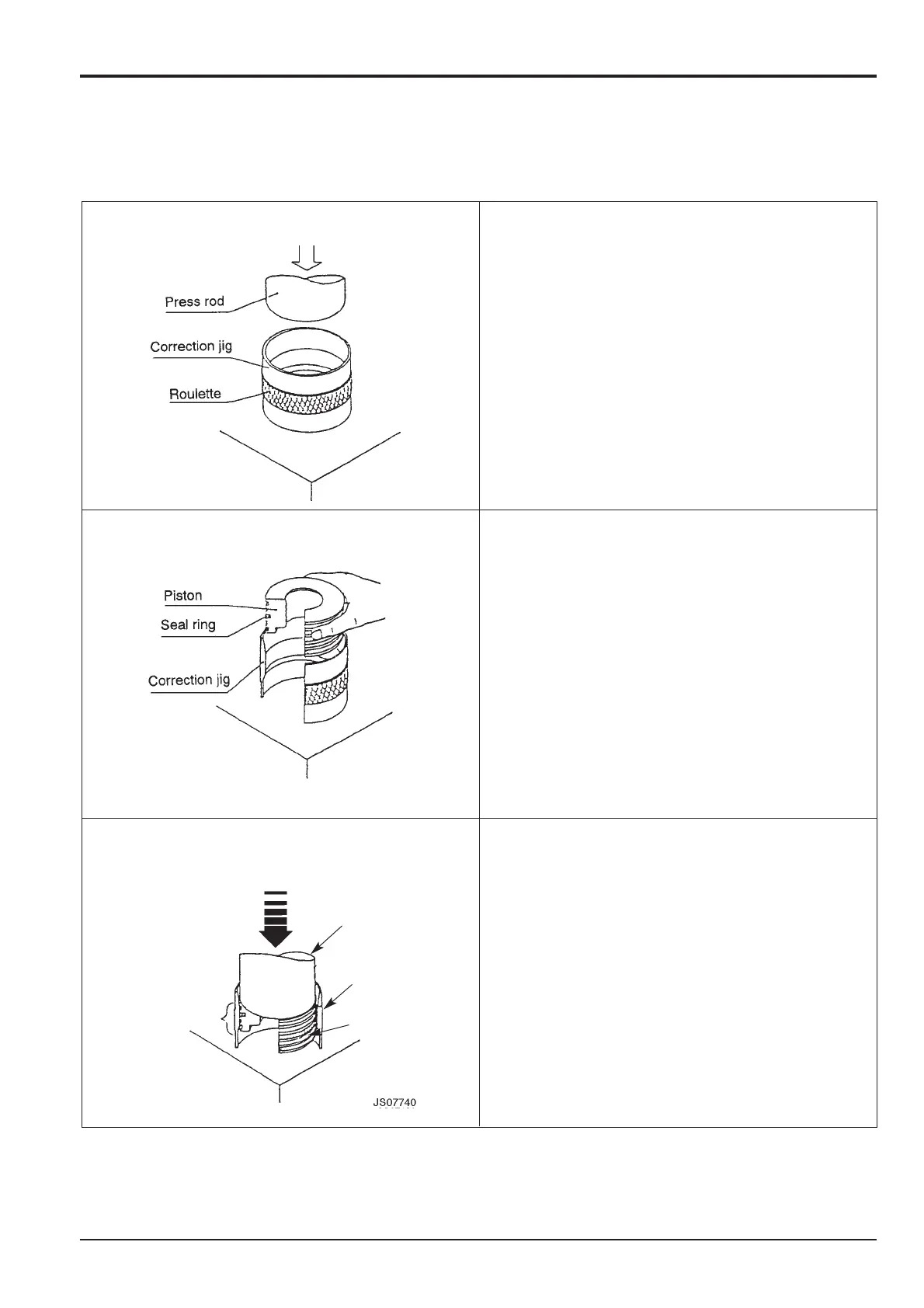

Slowly insert the piston, with the seal ring fitted, into the

correction jig.

Insert the piston evenly inside the correction jig.

Press the piston slowly with a press rod that has

smaller diameter than the piston, until the seal ring fits

correctly in the groove.

Note: Stop pressing temporarily for three to five

seconds when the piston reaches the point of

correction and then repress the piston to the end.

7. Correction jig preparation

8. Inserting the piston

9. Press fit

Correction range

Press rod

Correction jig

Piston

*

Loading...

Loading...