79 - 1

Section E

Hydraulics

9803/6400

Section E

79 - 1

Issue 1

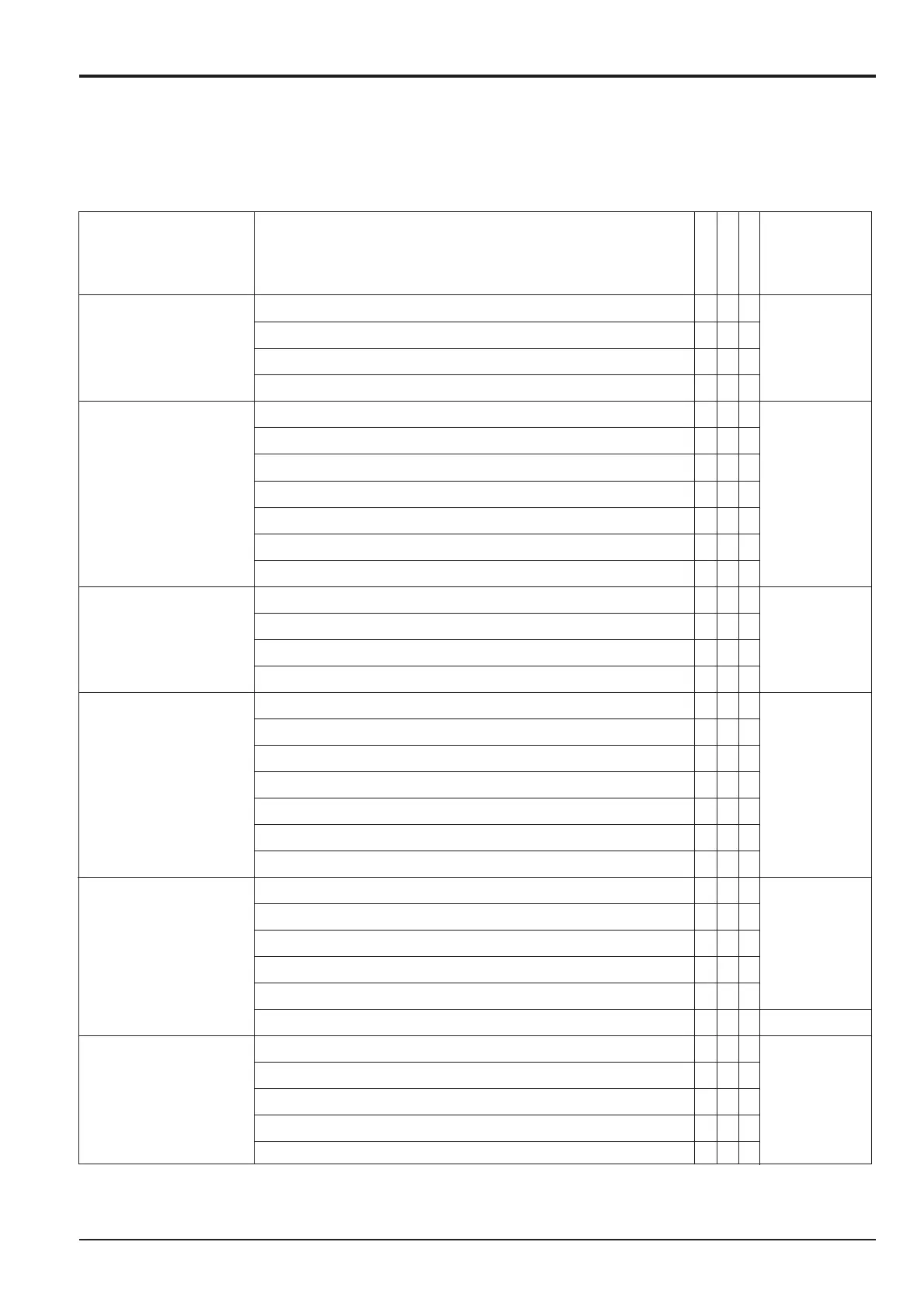

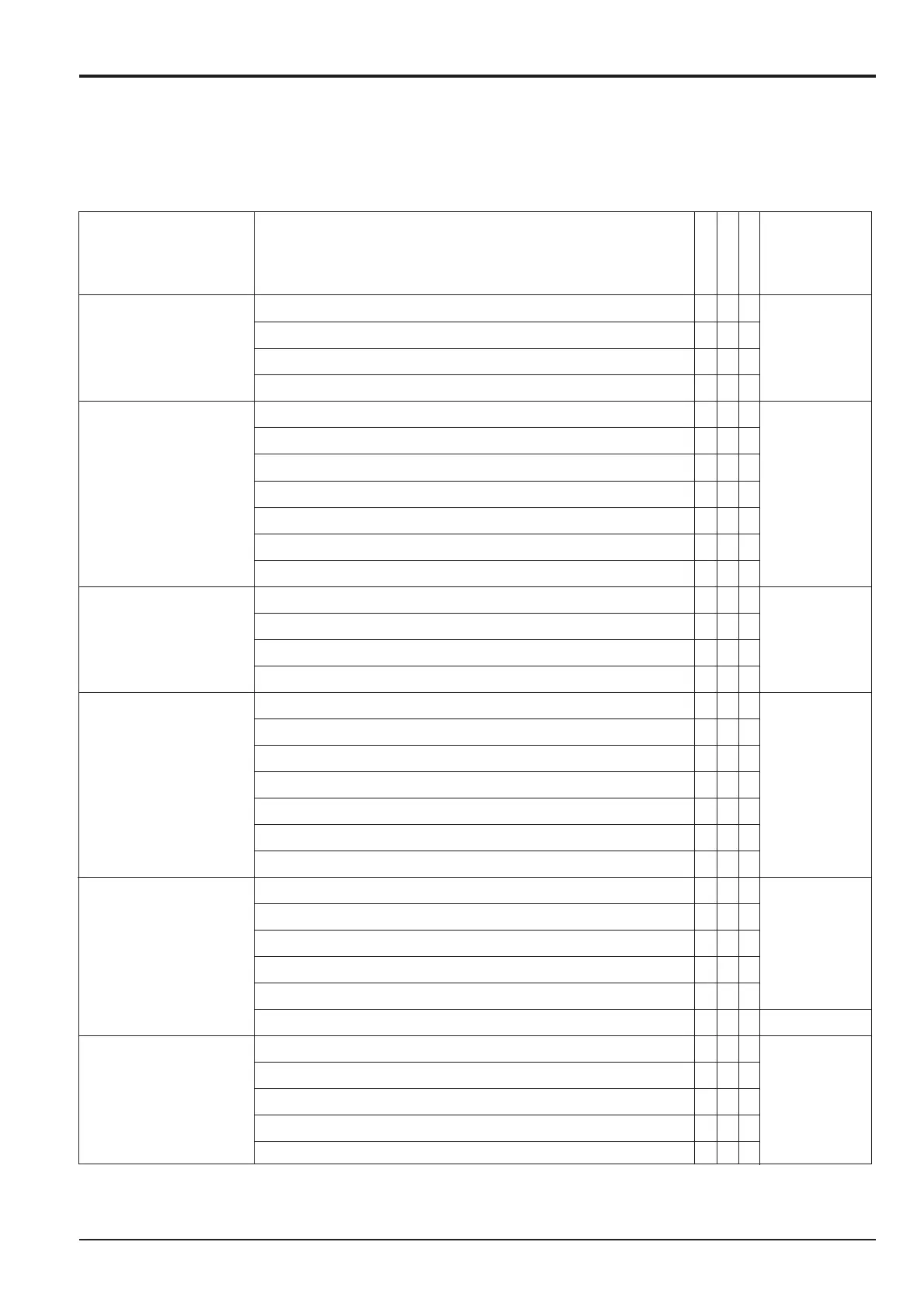

Hydraulic Rams

Maintenance Specifications

In order to ensure long life of the hydraulic ram, carry out inspection and maintenance regularly. If an abnormal point is found,

repair as soon as possible referring to the troubleshooting chart.

Inspection, Inspection,

Maintenance Point Maintenance Contents Note

Is the ram kept clean (especially the rod sliding part)? O

Appearance Is there oil leakage from piping installation and fixing points? O

Is there any peeling paint, separation or rust? O

Are the movements smooth and are there any abnormal sounds? O

Is the response good? O

Is there oil leakage from the sliding parts? O

Operation Is there internal leakage? O

Is the working pressure normal? O

Is the set pressure for the overload relief valve normal? O

Is the hydraulic oil dirty or deteriorated? O

Hydraulic Oil Is the hydraulic oil replaced periodically? O

Are the filters inspected periodically? O

Is the pin greasing sufficient? O

Is there any abnormal sound at the pins or seizure? O

Is there backlash or wear in the pins? O

Installation with Is the pin seal normal? O

Main Body Are the installation screws loose or missing? O

Tightening of the installation screws? O

Are the sliding parts worn? O

Are there scratches or dents on the sliding parts? O

Piston Rod Is there coating separation on the sliding parts? O

Are the sliding parts bent? O

Are there cracks in the welding or other damage? O

Are the bolts, nuts loose? O

Ram Cylinder Are the bolts, nuts tightened? O

(Including Piping) Are there cracks in the welding or other damage? O

Are there big depressions or dents in the cylinder? O

Daily

Monthly

Annually

When the rod

sliding part is

exposed for a

long period of

time apply

anti-rust oil to

the rod.

Loading...

Loading...