5 - 1

Section F

Transmission

9803/6400

Section F

5 - 1

Issue 1

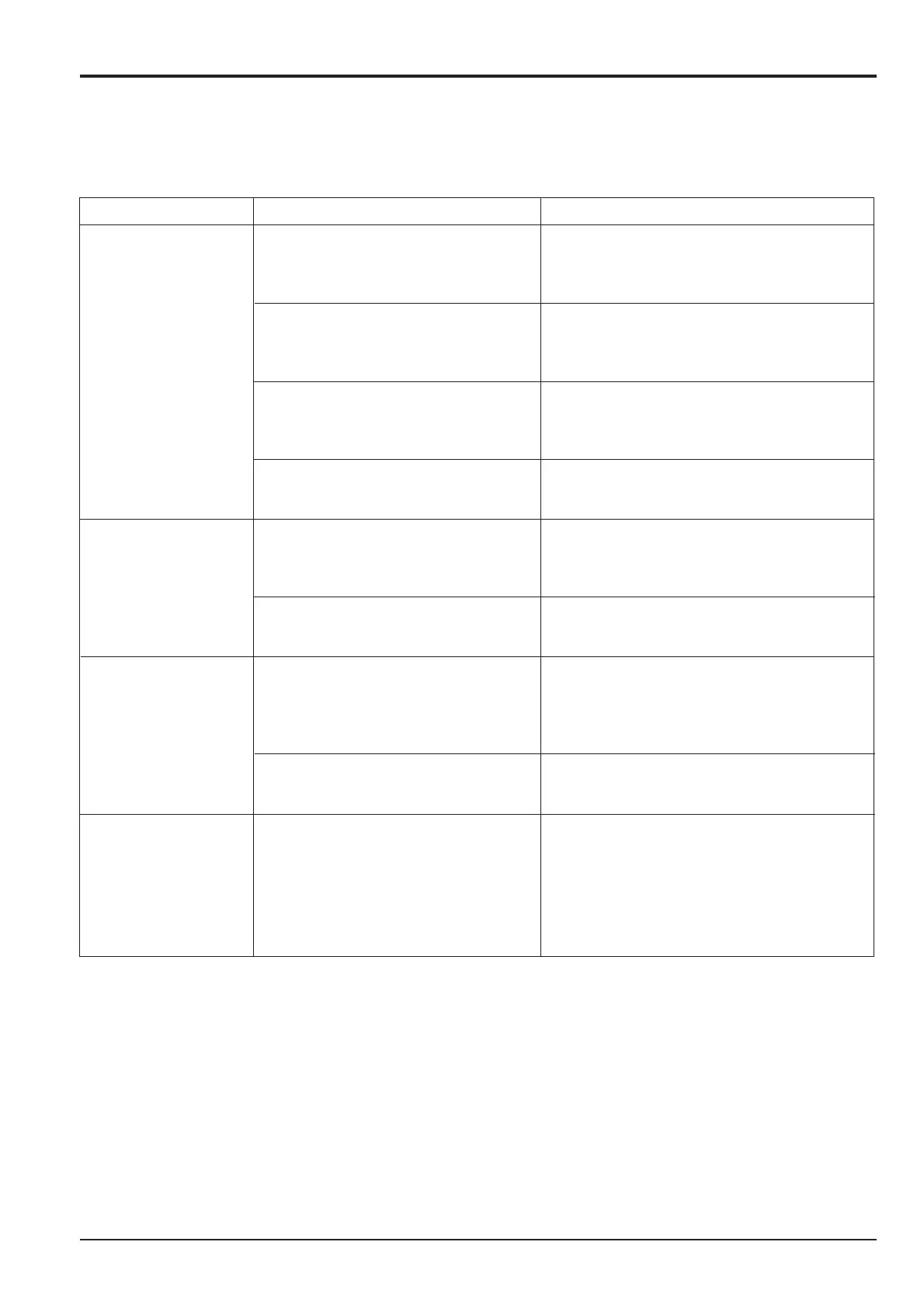

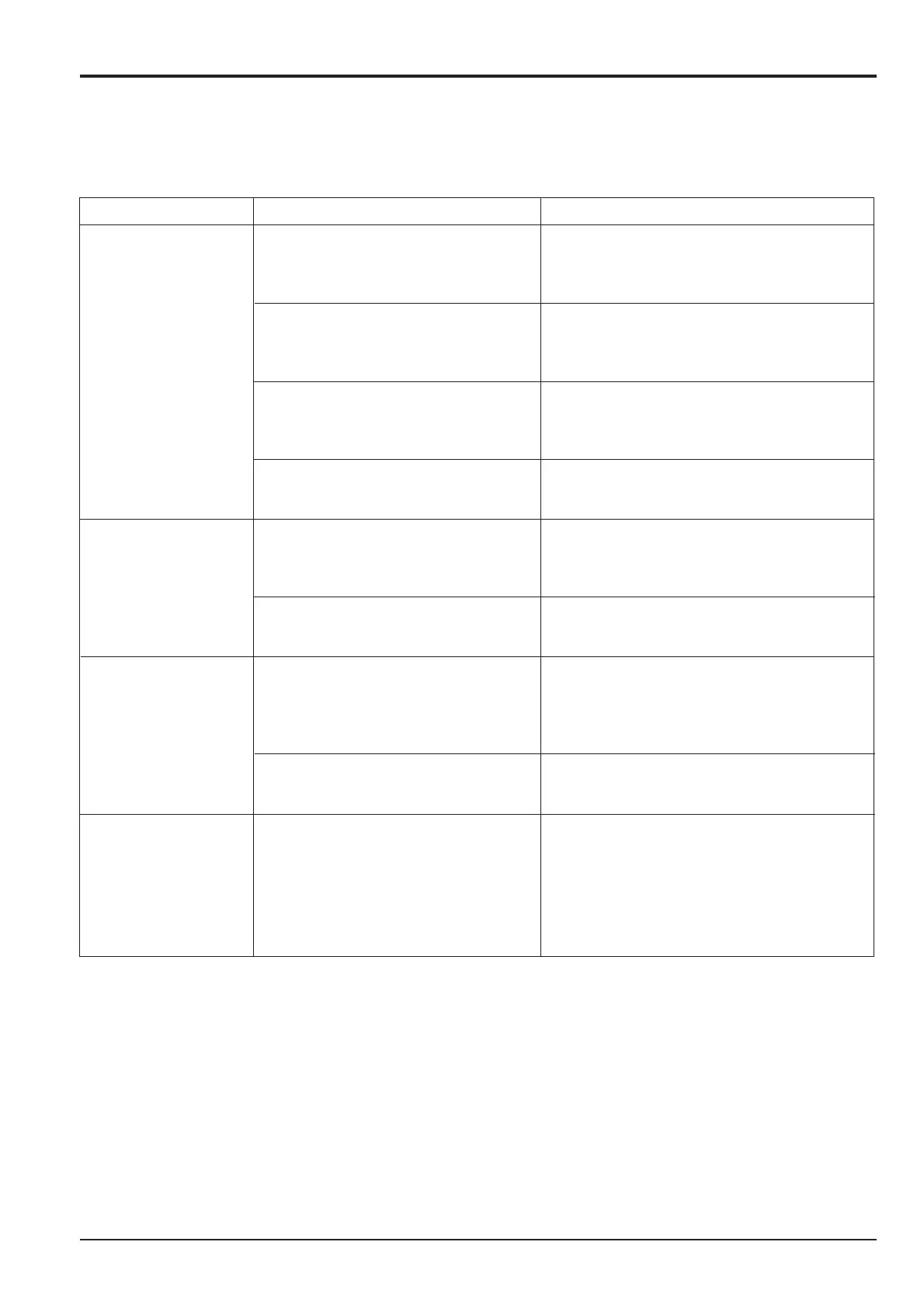

Motor/Gearbox

Fault Finding

Piston Motor

Fault Possible cause Countermeasure or remedy

1. Motor does not 1. Device other than the piston motor or Check whether or not the specified

run reduction gear may have malfunctioned. pressurised oil is delivered to the motor

input side and then inspect each device

and repair if necessary.

2. Sliding area of motor is abnormally worn Replace the excessively worn part. Remove

allowing the pressurised oil to escape. scratches and burrs from the surface and

completely clean all parts. Reassemble the

parts.

3. Improper operation resulting from Disassemble and replace the damaged part.

damage of important motor part. In this Completely clean all parts and reassemble.

case, abnormal noise is heard from the

motor itself.

4. Relief valve is activated because the Check the load state and operate the

motor is excessively loaded. machine under a load which matches the

relief pressure.

2. Motor revolution 1. Oil not supplied to motor at specified Check whether the specified pressurised

speed is rate due to problems in hydraulic pump, oil is delivered to the motor input side

insufficient pressure control valve, etc. and then inspect each device and

repair if necessary.

2. Specified revolution speed cannot After disassembly, check for abnormal

be achieved due to reduced wear of the sliding area and repair or

volume efficiency of motor. replace worn parts.

3. Motor revolution 1. Pressurised oil escaping Disassemble and replace excessively

speed varies through the drain port due to wear worn parts. Completely clean all parts

greatly on the sliding area of the motor. and reassemble them.

Also, revolution speed variation

resulting from wear in the bearing.

2. Motor load is excessive and the Check the load state and operate the

automatic 2-speed function is working. machine under a load which matches the

automatic 2-speed set pressure.

4. Oil leaks 1. Oil leaks due to damage of the oil seals Replace a broken oil seal or 'O'-ring with a

or 'O'-rings. new one. When inserting the oil seal, be

careful not to damage the lip. Since the safe

working temperature limit of the oil seal

and 'O'-ring is up to 80°C, it is necessary to

take steps to prevent the hydraulic oil

temperature from exceeding 80°C.

Loading...

Loading...