5 - 5

Sectyion F

Transmission

9803/6400

Section F

5 - 5

Issue 2*

Motor/Gearbox

Fault Finding (continued)

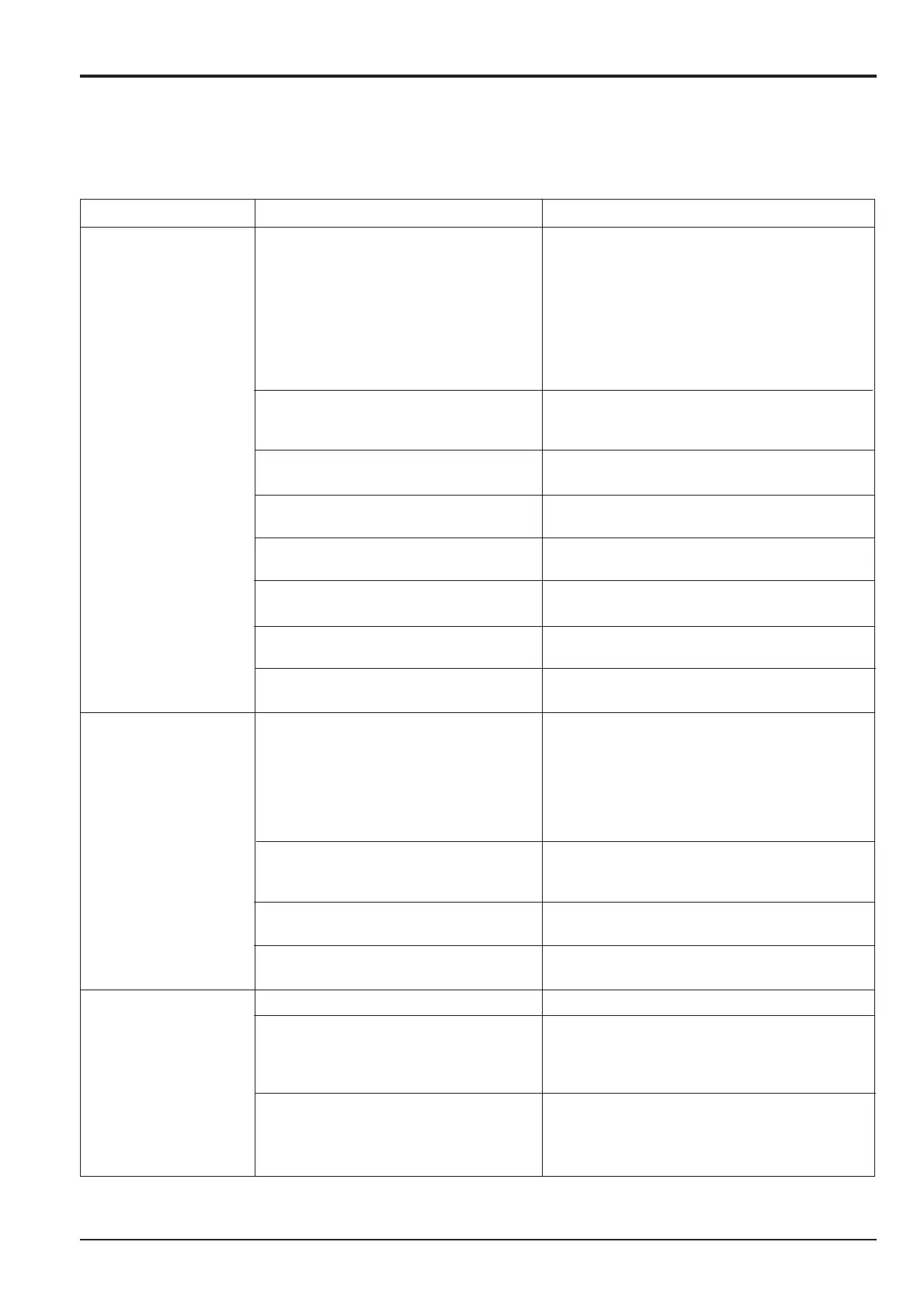

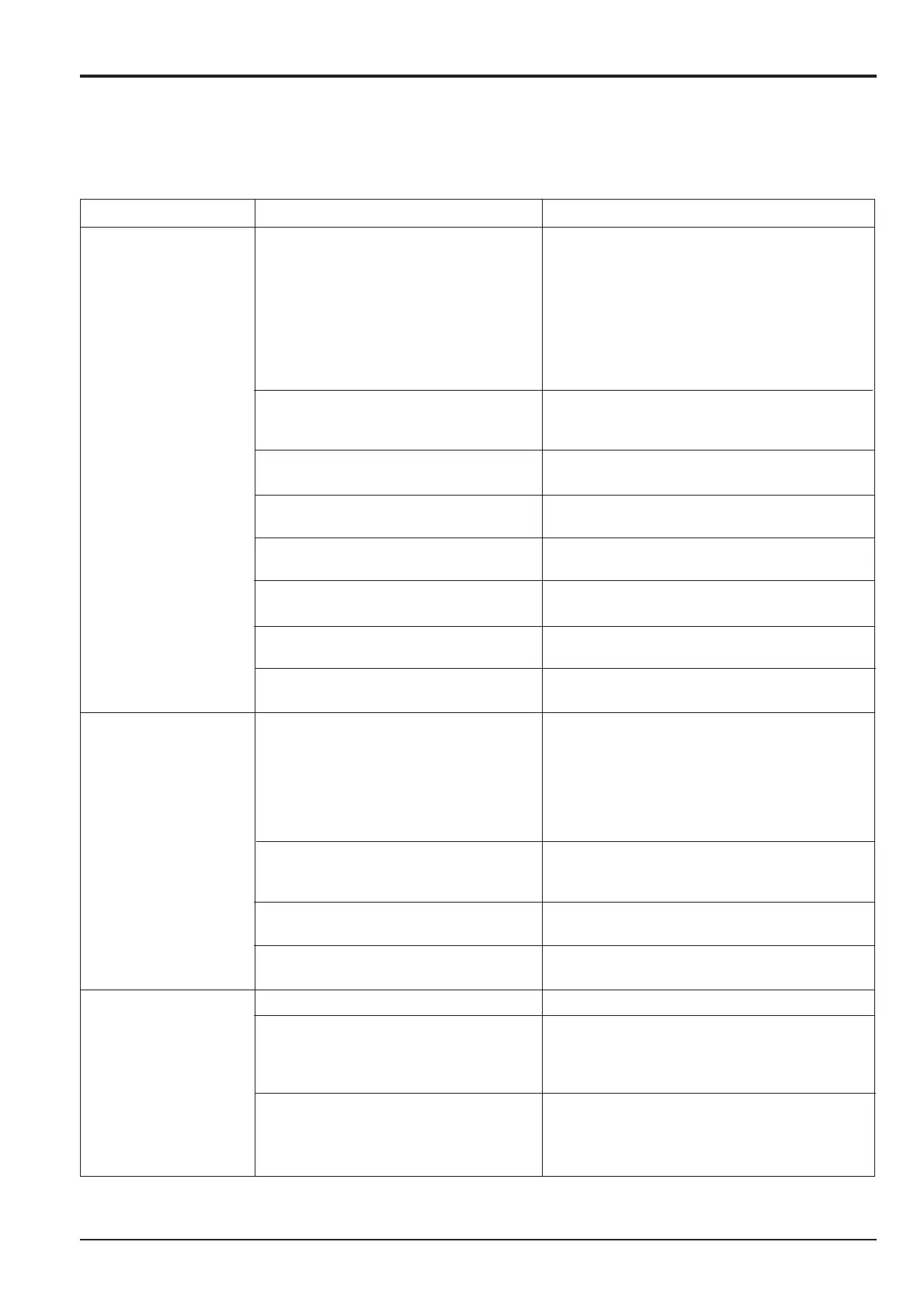

2-Speed Control Function

Fault Possible cause Countermeasure or remedy

1. Travel is not linear 1. Plunger is not switched

1) Foreign matter is caught between Completely remove foreign matter, repair

plunger and body. the damage and reassemble after cleaning.

Replace if damage or leakage is excessive.

2) Spring is not assembled correctly. Assemble spring in specified position.

3) Spring is broken. Renew spring.

4) Foreign matter is trapped in spool Completely remove foreign matter, repair

galleries. the damage and reassemble after cleaning.

Replace if damage or leakage is large.

2. Pressurised oil leaks due to abnormal Replace the 2-speed control piston.

wear of 2-speed control piston Completely remove foreign matter and

reassemble after cleaning.

3. 2-speed control piston is not assembled Assemble 2-speed control piston to the

correctly specified position.

4. Steel ball is abnormally worn. Replace steel balls. Completely remove

foreign matter and reassemble after cleaning.

5. Set pressure is rising due to Replace spool. Completely remove

abnormal wear of spools. foreign matter and reassemble after cleaning.

6. The orifice of the 2-speed piston cavity Confirm orifice diameter.

drain is incorrect.

7. The orifice of the 2-speed piston cavity Reassemble after cleaning.

drain is clogged.

8. Number of washers is different and set Reassemble using correct number of washers.

pressure is different on the left and right.

2.Will not go into 2nd. 1. Plunger is not switched

1) Foreign matter is caught between Completely remove foreign matter, repair the

plunger and body. damage and reassemble after cleaning.

Replace if damage or leakage is excessive.

2) Foreign matter is trapped in spool Completely remove foreign matter, repair

galleries. the damage and reassemble after cleaning.

Replace if damage or leakage is excessive.

2. Pressurised oil leaks due to abnormal Replace the 2-speed control piston.

wear of 2-speed control piston. Completely remove foreign matter and

reassemble after cleaning.

3. 2-speed control piston is not assembled Assemble 2-speed control piston to the

correctly. specified position.

4. The orifice of the 2-speed piston cavity Reassemble after cleaning.

drain is clogged.

3.Will not go into 1st. 1. Spring is not assembled correctly. Assemble spring to specified position.

2. Spring is broken. Replace spring. Completely remove foreign

matter, repair the damage and reassemble after

cleaning. Replace if the damage or leakage

is excessive.

3. Set pressure is rising due to abnormal Replace spool. Completely remove

wear of spools. foreign matter, repair the damage and

reassemble after cleaning. Replace if the

damage or leakage is excessive.

*

*

*

*

Loading...

Loading...