10 - 4

Other Measurements (continued)

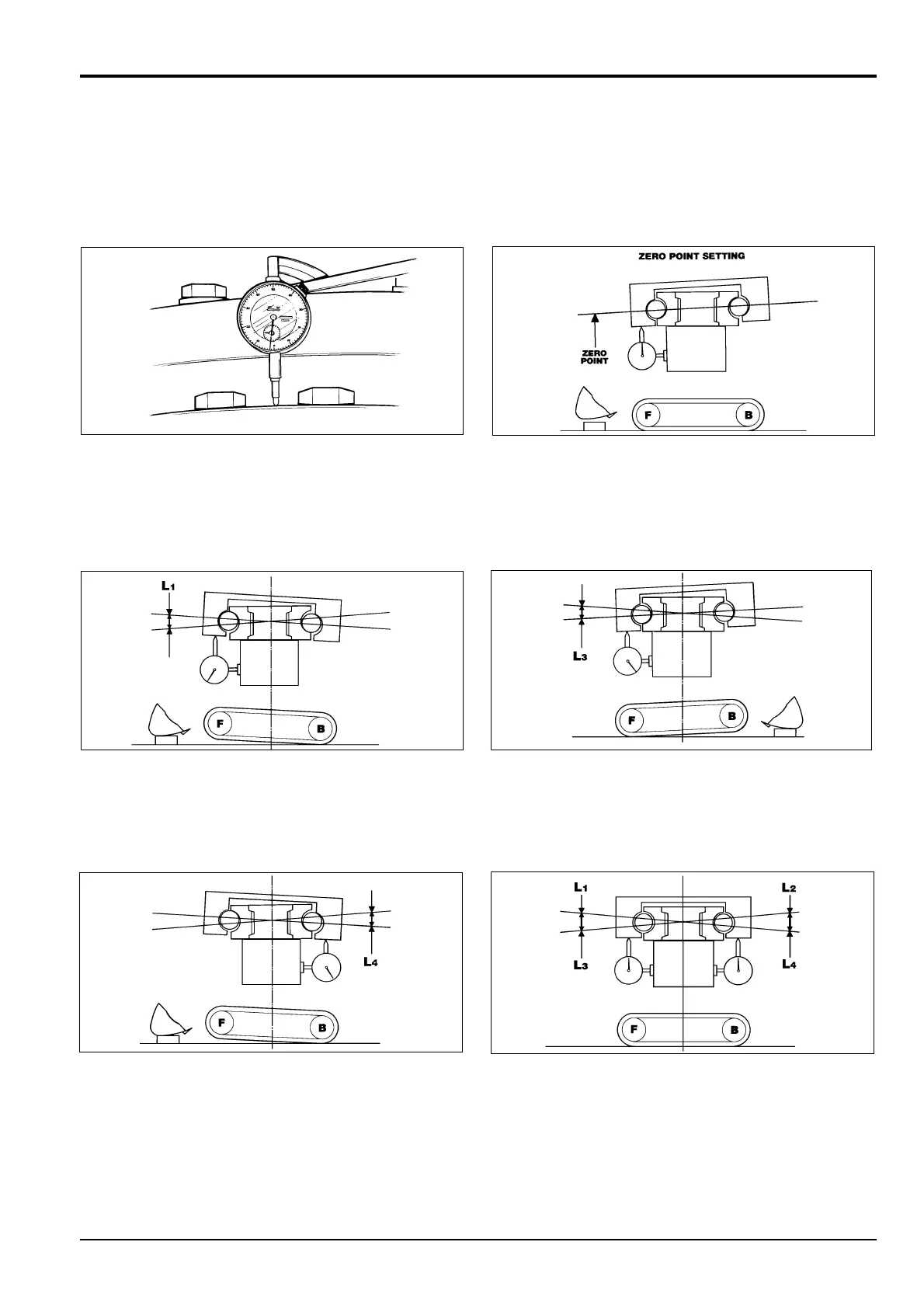

c. Lateral Movement in turntable bearing.

1. First set the Dipper in a perpendicular position and

position the bucket 200 mm above the ground, stop

the engine.

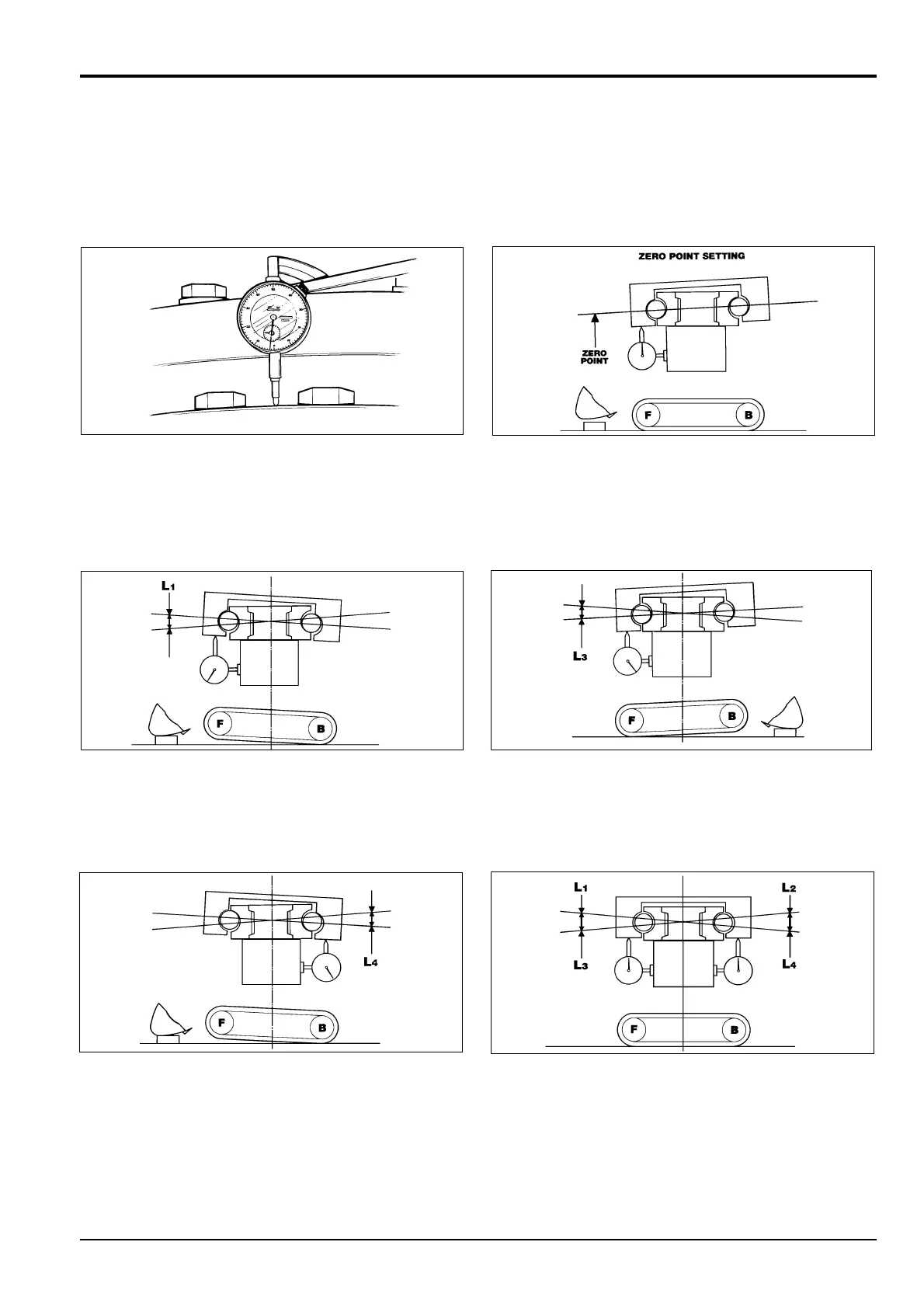

3. Start the engine and lift the main body with the

bucket, when the bottom of the shoe is 100 mm

above ground, note the reading on the dial gauge.

The needle will turn in the counter clock wise

direction. This value becomes L1, lower the body to

the ground and confirm the needle reads zero.

5. Next, place the dial gauge on the rear of the vehicle

and repeat the two above procedures to obtain L2

and L4.

2. Install a dial gauge and set the needle to the Zero

Point.

4. Then rotate the main body 180° and repeat the

procedure, this time the needle will rotate clock wise.

This value becomes L3.

6. The lateral movement is shown as the result of the

equation.

Note. Always stop the engine when installing or removing

the dial gauge or reading the dial gauge.

Section 3

Routine Maintenance

9803/6400

Section 3

10 - 4

Issue 1

Performance Evaluation JS200/JS240

Loading...

Loading...