8 - 19

Gearbox Inspection

All parts should be inspected for signs of wear or damage,

paying particular attention to the parts detailed below.

Section F Transmission

9803/6020

Section F

8 - 19

Issue 1

Track Gearbox

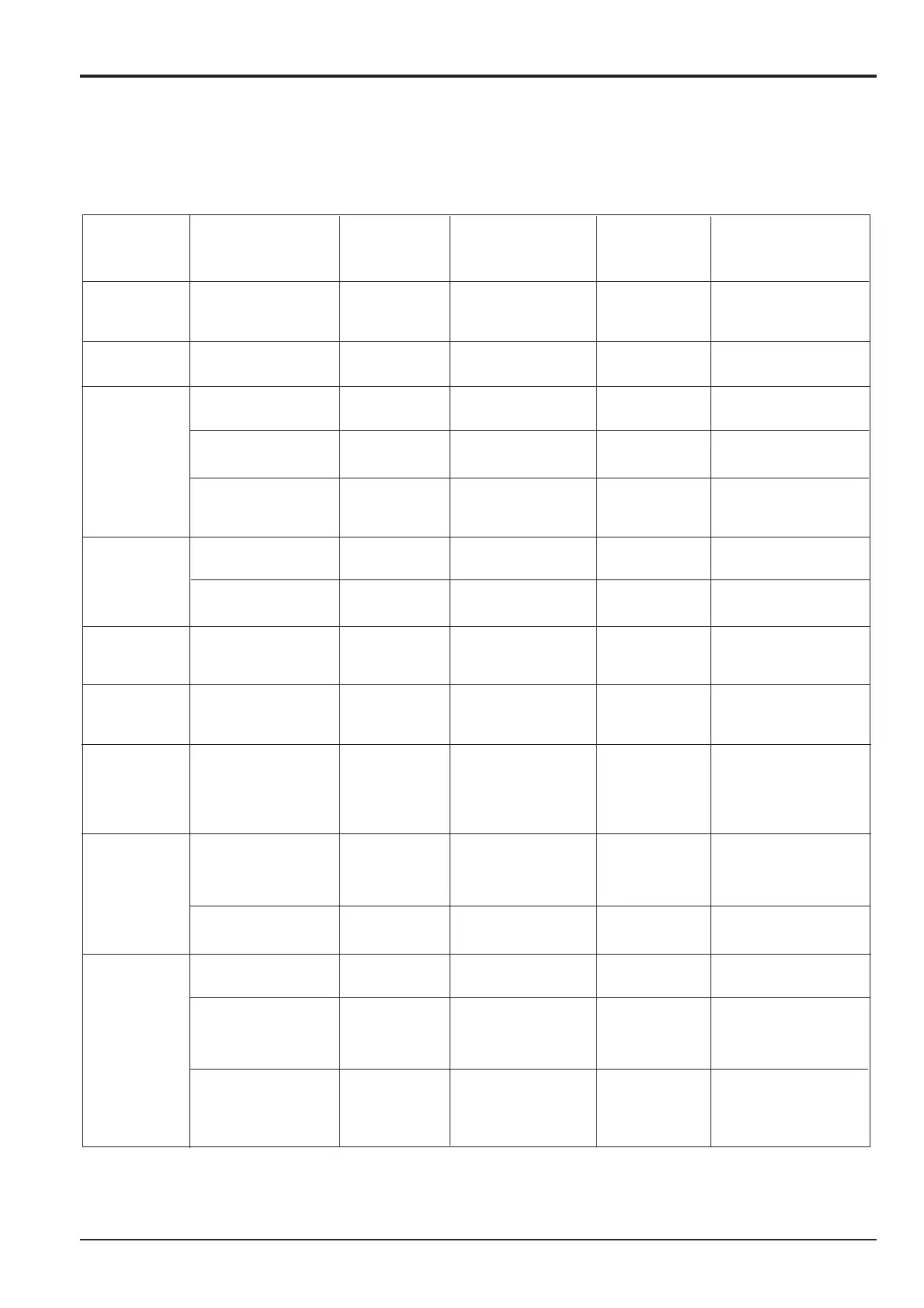

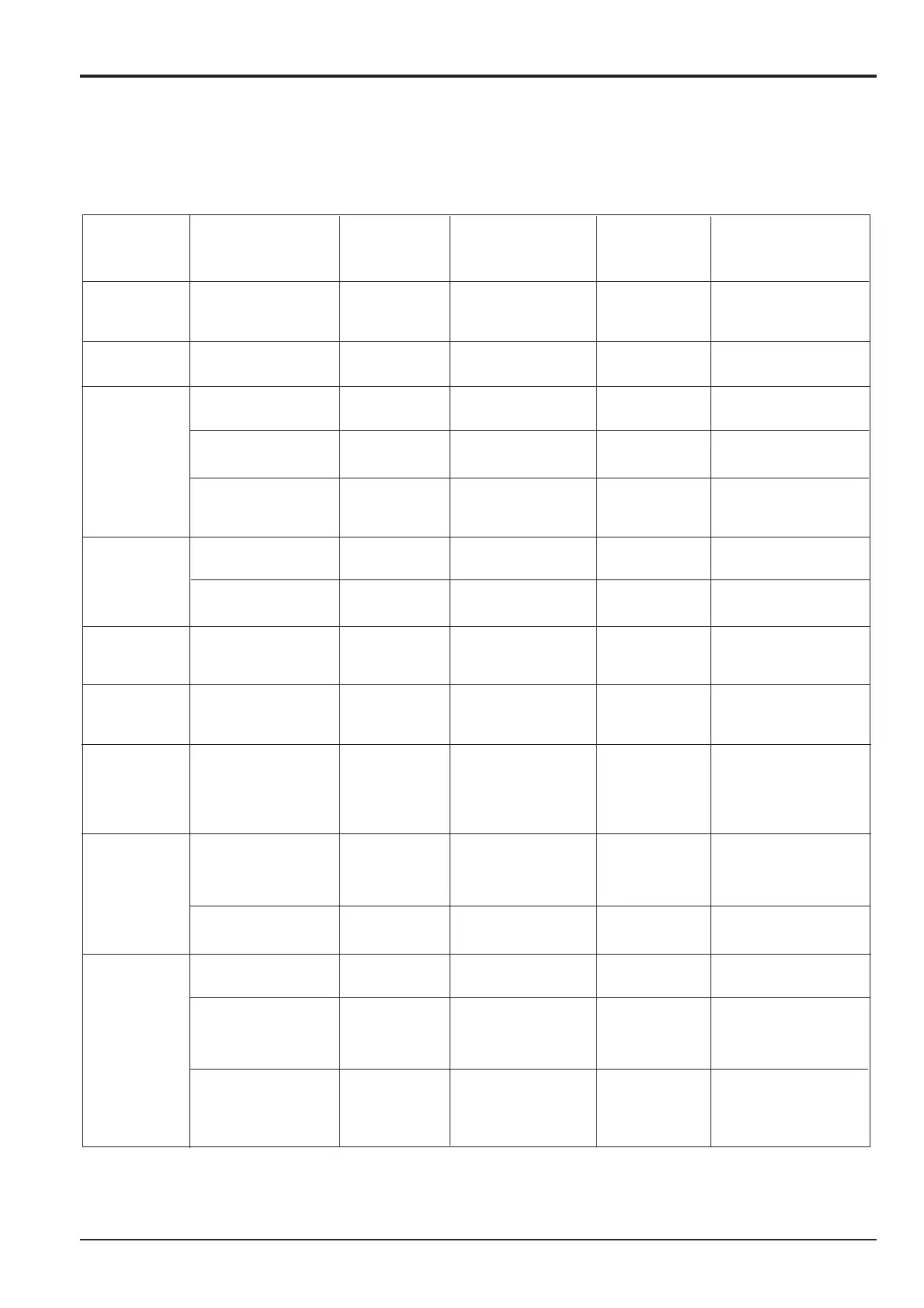

Part(s) Inspection Standard Permissible Measuring Corrective Action

Measurement Value Tolerance/ Tool

Area Condition

a. Hub 1 Pin bore area Surface No scratches, Visual check

roughness eccentric wear or

12S thermal seizure

b. Spindle 2 Bore diameter of ø 19 mm Max. ø 19.056 mm Cylinder gauge

reamer hole (0.748 in) (0.750 in)

c. RV gear 4 Flaking on the 0 Flaking 6.5 mm2 Visual check

RV gear 5 trochoid gear surface

Pitting on the 0 Flaking 6.5 mm2 Visual check

trochoid gear surface

Flaking on the needle 0 Flaking 6.5 mm2 Visual check

roller bearing 23

aperture.

d. Crankshaft Flaking on the 0 Flaking 6.5 mm2 Visual check

9 eccentric lobes.

Pitting on the 0 Flaking 6.5 mm2 Visual check

eccentric lobes.

e. Distance Wear on the seal 0 Wear 0.2 mm Contour/

piece 10 surface. (0.008 in) roughness

tester.

f. Floating Seal surface Surface No damage or Visual check

seal 31 roughness rust is

0.4S permissible

g . Thrust Wear of sliding Surface Wear 0.010 mm Contour/ Lap the slide surface

plate 153 surface for piston roughness (0.0004 in) roughness to correct slide

damage.

shoe 106. 0.4S tester (Correctable wear

0.020mm)

h. Cylinder Eccentric wear of Surface Wear 0.005 mm Contour/ Lap the slide surface

block 104 slide surface for roughness (0.0002 in) roughness to correct slide damage.

timing plate 109 0.4S tester (Correctable wear

0.020mm)

Cylinder boreø 17.004 mm Max. ø 17.014 mm Cylinder

diameter (0.069 in) (0.6698 in) gauge

j. Piston 105/ Outer diameter of ø 16.995 mm Min. ø 16.985 mm Indicator

piston shoe piston 105 (0.67 in) (0.668 in) micrometer

100

assembly Eccentric wear of Surface Wear 0.005 mm Contour/ Lap the slide surface

thrustplate sliding roughness (0.0002 in) roughness to correct slide damage.

surface of shoe 106 0.4S (Correctable wear 0.020

mm)

Backlash of ball joint 0.1 mm 0.2 mm Lever type dial

between piston 105 (0.004 in) (0.008 in) gauge

and shoe 106

Loading...

Loading...