8 - 20

Section F Transmission

9803/6020

Section F

8 - 20

Issue 1

Track Gearbox

Inspection (cont’d)

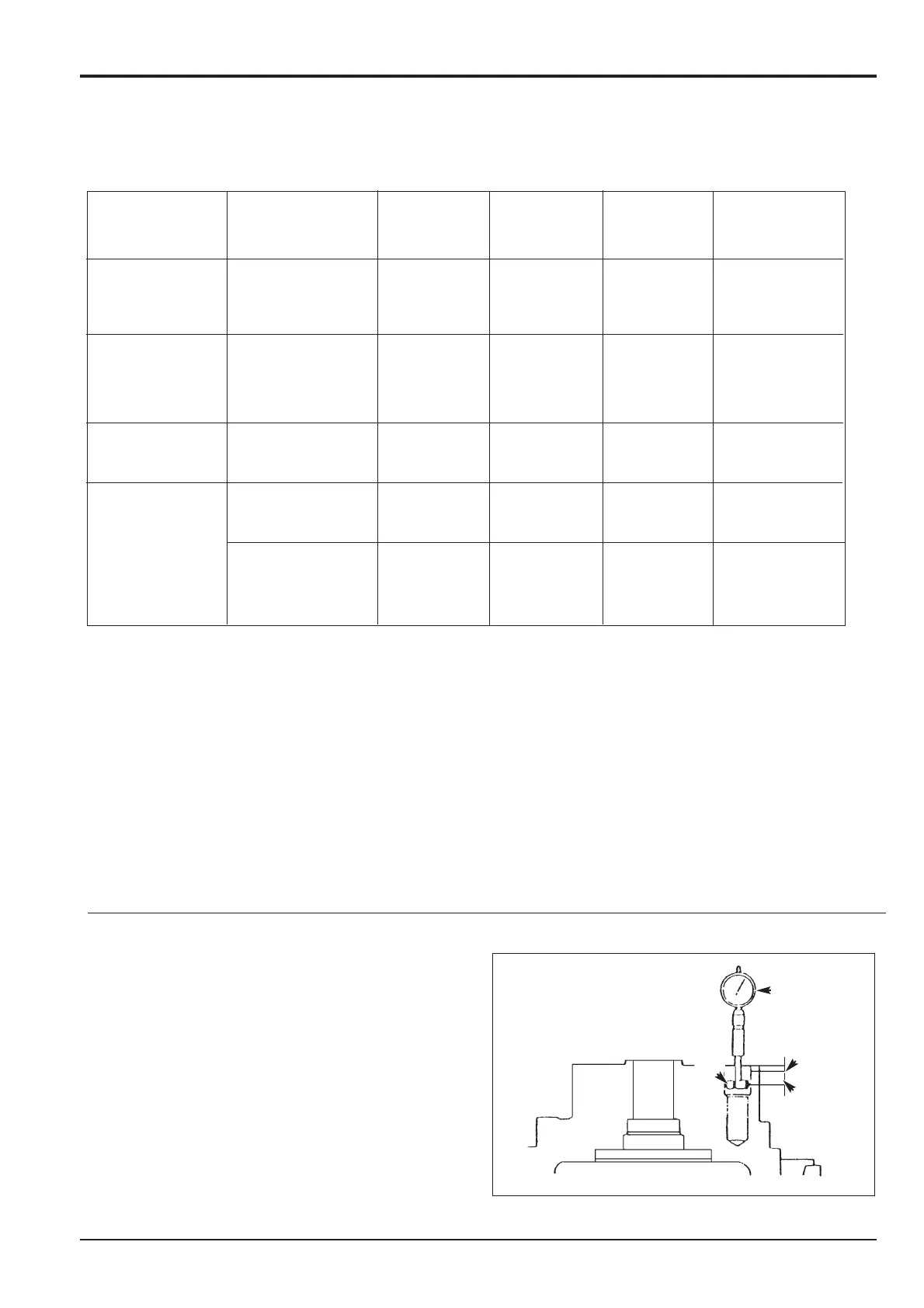

Part(s) Inspection Standard Permissible Measuring Corrective Action

Measurement Value Tolerance/ Tool

Area Condition

k. Timing plate Wear for cylinder Surface Wear 0.005 mm Contour/ Lap the slide surface

109 block 104 roughness (0.0002 in) roughness to correct any slide

0.4S tester damage. (Correctable wear

0.020 mm)

m. Spool 123/ Clearance between Clearance Clearance Indicator

rear flange outer diameter of 0.012 - 0.038 mm micrometer

101 spool 123 and spool 0.018 mm (0.0015 in) Cylinder gauge

hole of rear flange (0.0005 -

101 0.0007 in)

n. Piston Backlash of ball joint Backlash Backlash 0.2 mm Lever type dial

assembly between piston 161 0.1 mm (0.008 in) gauge

161/162 and shoe 162 (0.004 in)

p. Brake Outer surface Surface No scratches, Visual check

friction roughness uneven wear or

plate 115 12S thermal seizure

Plate thickness 2.8 mm Min. 2.5 mm Slide calipers

(0.11 in) (0.1 in) or cross and visual

groove must check

remain.

2 Measurement Procedures

Component measurements should be carried out in a

clean area, i.e. free from dust and contaminants, where

the temperature is 18 °C - 20 °C (64.4 °F - 71.6 °F).

After thorough cleaning arrange the components on a

working surface of JIS Class 2 or better.

Take measurements carefully and at least twice to verify

accuracy.

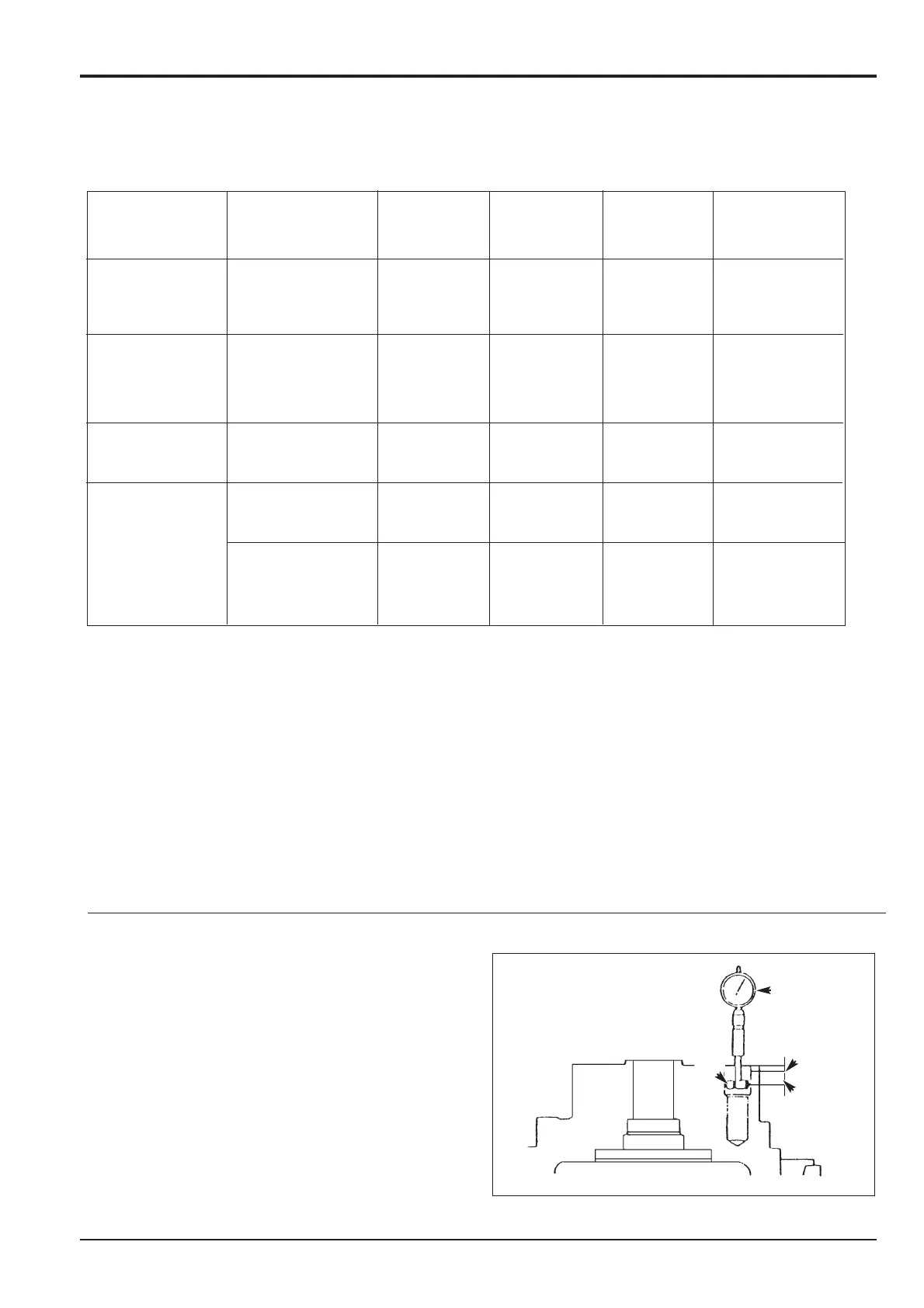

a Measurement of spindle 2 reamer hole bore

diameters - use a 1 mm full scale dial gauge C and

a cylinder gauge D of measuring range 18 - 35

mm. Set up the dial gauge - insert the cylinder

gauge into a 19 mm standard ring gauge and zero

the dial scale.

Transfer the cylinder gauge to one of the reamer

holes and measure the diameter 3 mm down (point

A) and then 10 mm down (point B). Rotate the

cylinder gauge two or three times at each point and

make a note of the minimum reading. For tolerance

see Wear Limits Table, item 1 (b).

Repeat for the other two reamer holes.

299610

10

3

CC

AA

BB

DD

Loading...

Loading...