8 - 21

2 Measurement Procedures (continued)

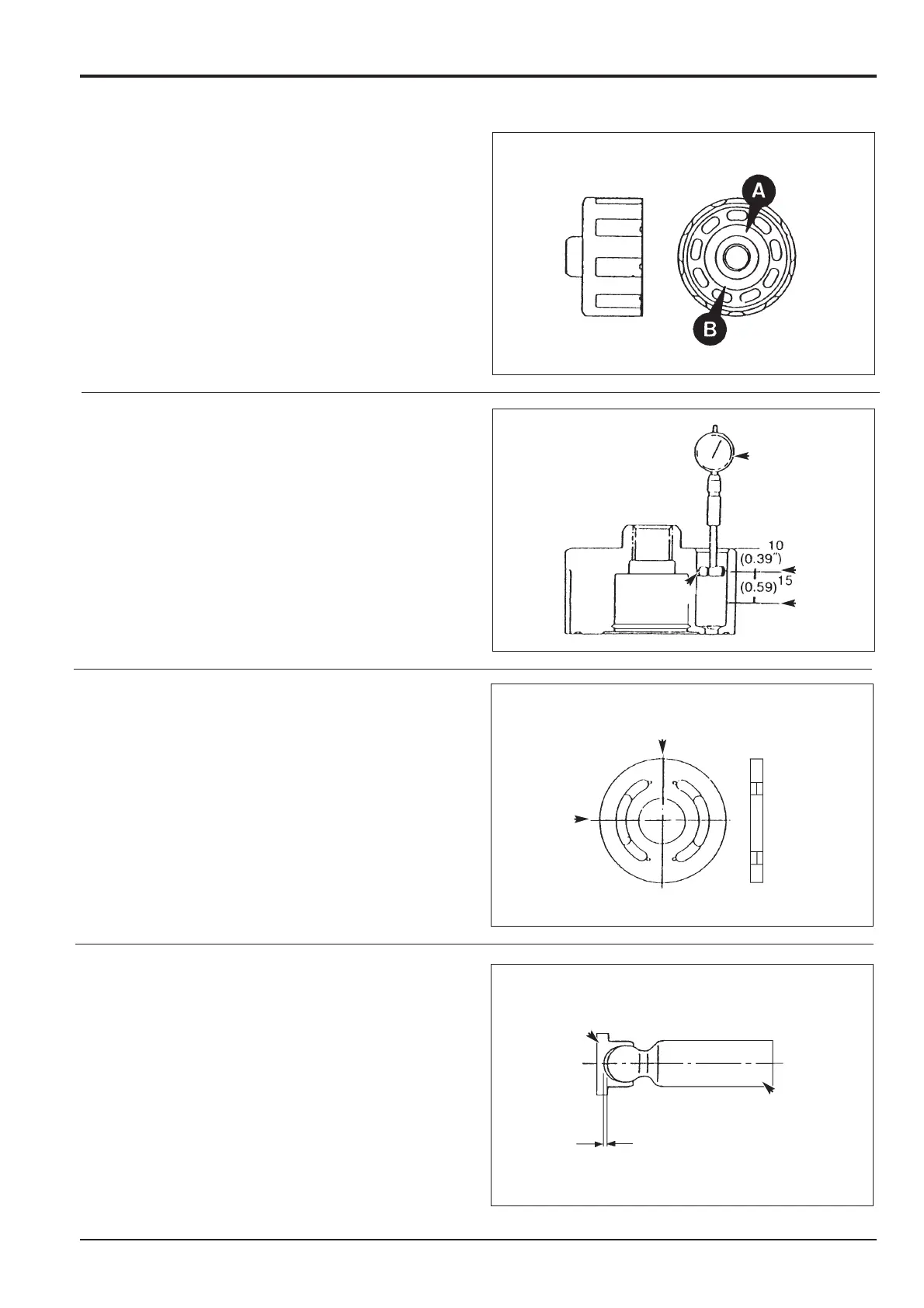

b Measurement of eccentric wear of timing plate surface

of cylinder block 104 - use a contour and roughness

tester to measure the wear at points A and B. For

tolerance, see Wear Limits Table, item 1 (h).

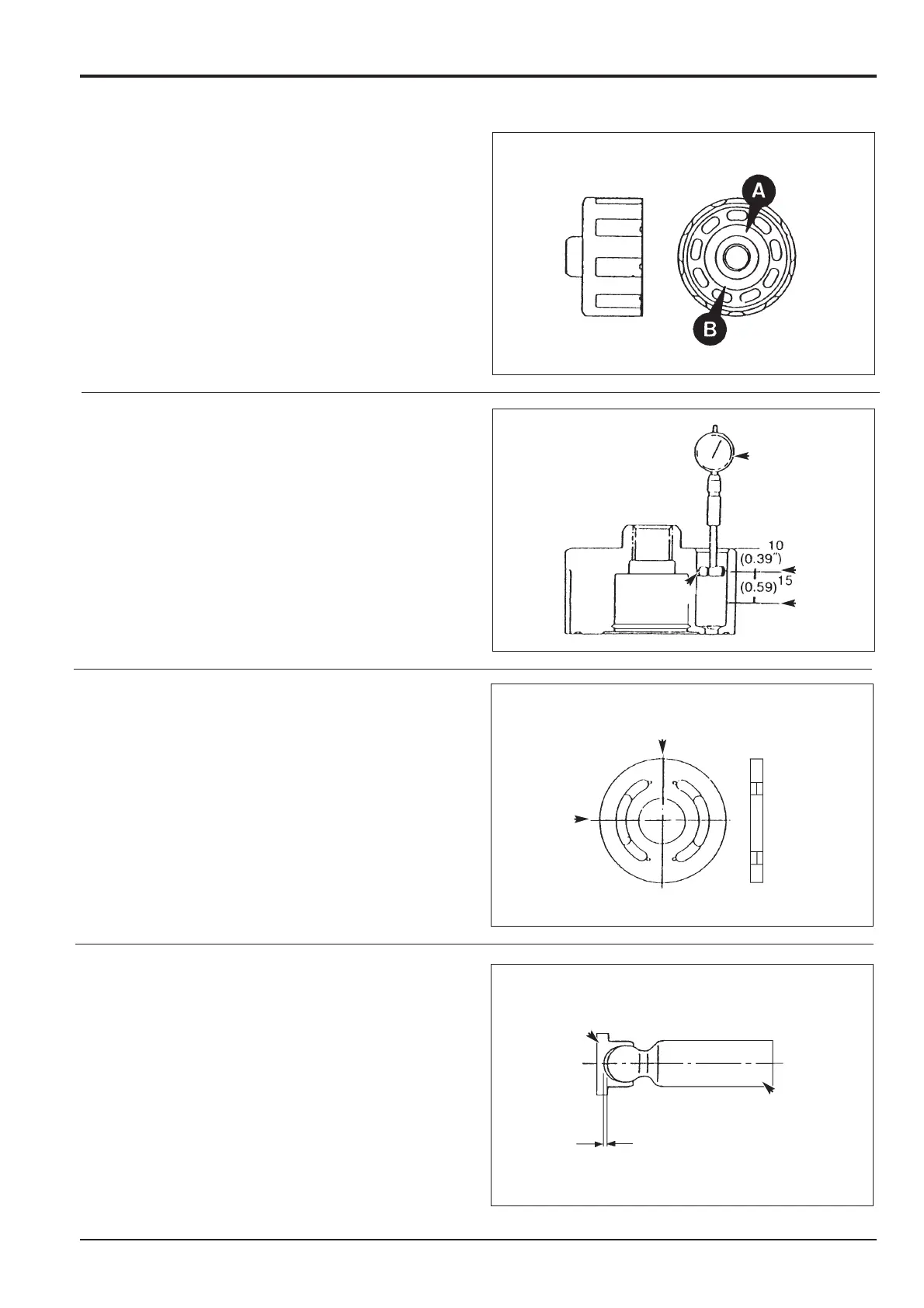

c Measurement of bore hole diameter of cylinder block

104 - use a 1 mm full scale dial gauge C and a cylinder

gauge D of measuring range 10 - 18 mm. Set up the dial

gauge by inserting the cylinder gauge into a standard 17

mm ring gauge. Zero the dial scale.

Transfer the cylinder gauge to one of the cylinder bore

holes and measure the diameter 10 mm down (point E)

and then 15 mm down (point F). Rotate the cylinder

gauge two or three times at each end point and make a

note of the minimum reading. For tolerances, see Wear

Limits Table, item 1 (h).

Repeat for the other eight cylinder bores.

d Measurement of wear on sliding surface of timing plate

109 - use a contour and roughness tester to measure

the wear at points G and H. For tolerances, see Wear

Limits Table, item 1 (k).

e Measurement of lateral ball joint wear between piston J

and shoe K. For tolerances see Wear Limits Table, item

1 (j).

Section F Transmission

9803/6020

Section F

8 - 21

Issue 1

Track Gearbox

299620

299630

299640

299650

CC

EE

FF

DD

GG

HH

KK

JJ

Loading...

Loading...