8 - 40

Setting-up Procedures

Pre-load of Bearings 21

1 Install the main bearing pre-load adjusting jig (see

Service Tools, Section 1) into the spindle 2, making sure

the jig seats evenly with bearing 21 and does not foul

taper bearing 22. Tighten the jig nut to a torque of 39.2

Nm (28.9 lbf ft).

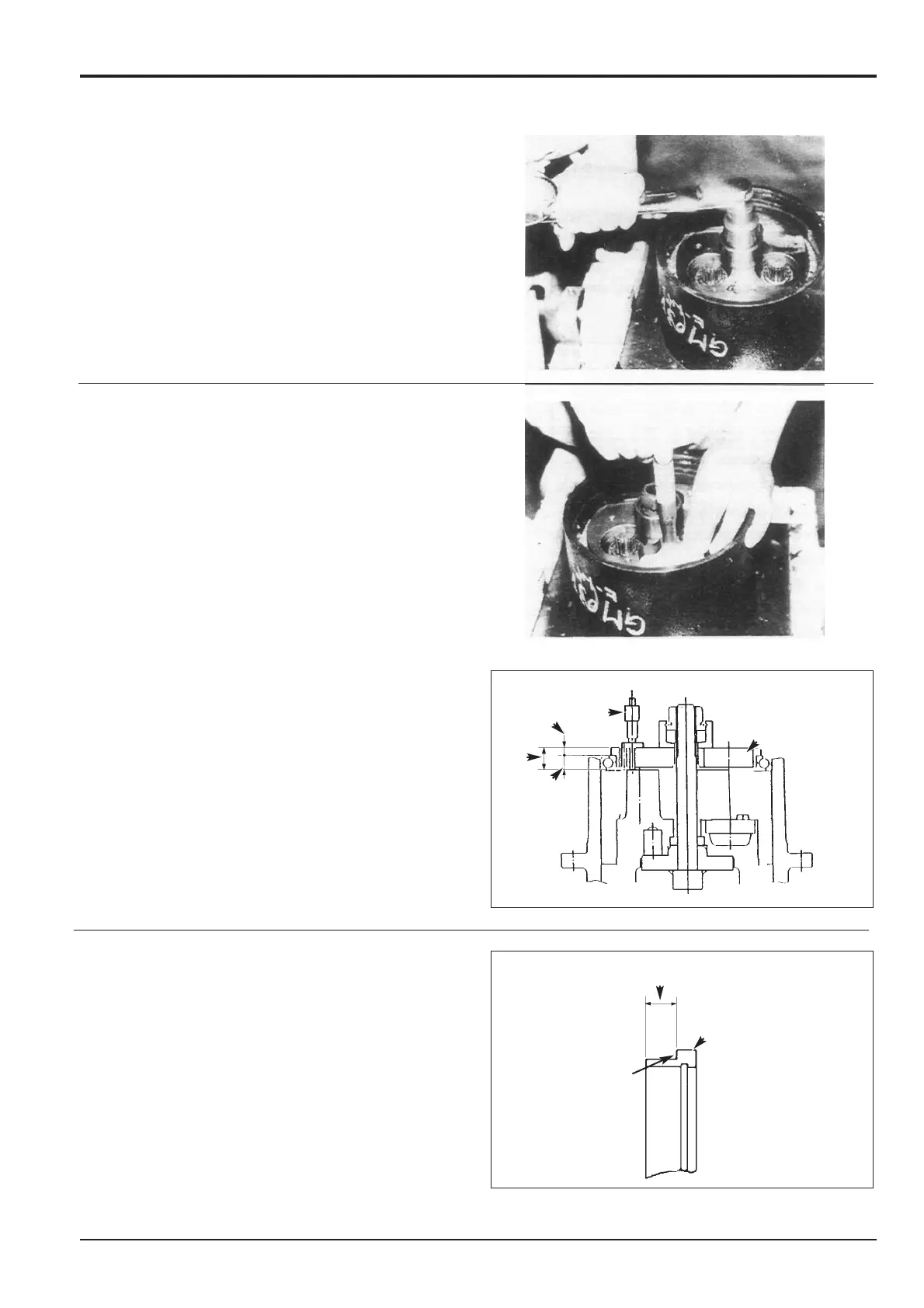

2 Measure depth A via the measurement hole in jig E

using a depth micrometer F. If not already known,

measure the thickness B of the lip of jig E.

Calculated dimension C (i.e. A - B) determines the

required dimension D of holding flange (see step 3).

3 Measure dimension D on the existing holding flange 3.

Proceed according to the following guidelines:

a If dimension D is less than the calculated dimension

C, grind surface G to achieve the required measurement

before assembling.

b If dimension D is within the tolerance of the

calculated dimension C, use the holding flange as it is.

c If dimension D is greater than the calculated

dimension C replace both the holding flange 3 and the

spindle 2. Having reached the appropriate point of the

assembly procedure, re-check the bearings pre-load as

described above.

Section F Transmission

9803/6020

Section F

8 - 40

Issue 1

Track Gearbox

2879840

287950

DD

33

GG

EE

FF

AA

CC

BB

Loading...

Loading...