7BOEING 787: FIBER INSPECTION AND CLEANING

EFFECT ON SIGNAL PERFORMANCE

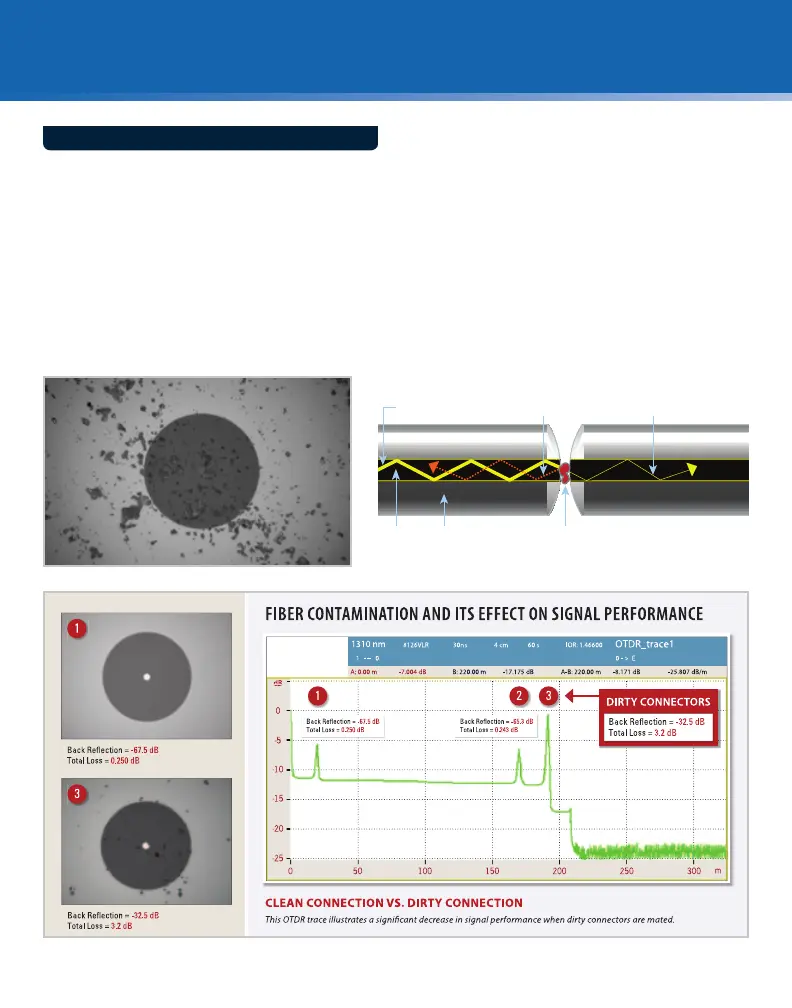

Dirt is everywhere, and a typical dust particle (2–15 μm in diameter) can signicantly aect signal performance

and cause permanent damage to the ber end face. Most eld test failures can be attributed to dirty connectors,

and most of them are not inspected until the problem is detected, after permanent damage has already occurred.

When dirt particles get on the core surface, light becomes blocked, creating unacceptable insertion loss and

back-reection. Furthermore, these contamination particles can permanently damage the glass interface by

digging into the glass and leaving pits when mated, causing further signal loss. Damage also occurs when large

particles of dirt on the cladding layer and/or the ferrule cause barriers that prevent physical contact, creating air

gaps between the ber connection. These large particles are also known to break apart and migrate across the

ber surface when mated.

Light Transmitted Insertion Loss

DIRTY CONNECTION

Core Cladding

Back Reflection

Dirty Fiber

THE PROBLEM

Loading...

Loading...