RXF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

070.410-IOM (JAN 12)

Page 33

an allowance in the readings must be made by subtracting

approximately 0.02 VDC per 1000 feet of elevation above

sea level. Barometric pressure can generally be ignored but

in extreme cases may be compensated for by adding/sub-

tracting 0.002 VDC for each 0.1 inch of barometric pressure

(adjusted to sea level) above/below 0 PSIG. Therefore, if

(PE-4) is measured at 5000 feet elevation under relatively

normal weather conditions, the output voltage should differ

by 0.10 VDC to read between 1.38 VDC and 1.62 VDC.

5. Subtract 1 from the voltage.

6. Multiply by 25.

7. This result is the absolute suction pressure (PSIA). Subtract

14.7 to obtain PSIG which the Operating display will indicate.

8. Isolate the oil pressure transducers (PE-1 & PE-2) from

the package and depressurize. NOTE: Recover or transfer

all refrigerant vapor, in accordance with local ordinances,

before opening to atmosphere.

9. Measure the voltage of (PE-1 & PE-2) on connector (P5A)

(terminals 5 and 6) on the analog board.

10.

The voltage reading should be between 1.1 VDC and 1.29

VDC at standard atmospheric pressure. (PE-1

& PE-2

) and

(PE-3) have a span of 500 PSI as compared to (PE-4) with a

span of 200 PSI. Therefore, atmospheric pressure changes

have a lesser effect which is 0.0067 VDC per 1000 feet of

eleva tion and 0.00067 VDC per 0.1 inch Hg baro metric de-

viation.

11. Subtract 1.2 from the voltage.

12. Multiply by 75, the result will be PSIG.

13.

Since the discharge pressure (PE-3) cannot be closed

off from its sensing point (code require ments), remove all

transducers from atmosphere and open them to their sensing

points so all transducers can equalize to separator pressure.

14. Measure the voltage of (PE-3) on connector (P5B) (ter-

minals 5 and 6) on the analog board.

15. Test complete.

PRESSURE TRANSDUCERS REPLACEMENT

1. Shut off control power.

2. Close the applicable transducer isolation valve. NOTE: To

change the discharge pressure transducer ( PE-3), it will be

necessary to depressurize the entire compressor package.

Follow "General Instructions For Replacing Compressor Unit

Components" section before going to step 3.

3. Remove DIN connector screw, then remove DIN connector

from the transducer.

TRANSDUCER CONNECTION

Suction Pressure PE-4

Discharge Pressure PE-3

Oil Pressure PE-1 & PE-2

4. Unscrew the transducer using a wrench on the metal hex at

the base of the transducer. DO NOT ATTEMPT TO LOOSEN

OR TIGHTEN TRANSDUCERS BY THEIR TOP CASING.

5. Install new transducer, reconnect DIN connector, and

retighten DIN connector screw.

6. Recalibrate. NOTE: If replacing older hard-wired trans-

ducer, cut cable at back of old transducer and rewire to

the Danfoss unit.

7. Reopen the transducer isolation valve or compressor pack-

age isolation valves.

8. Turn on control power.

SLIDE VALVE TRANSMITTER

REPLACEMENT - SLIDE STOP

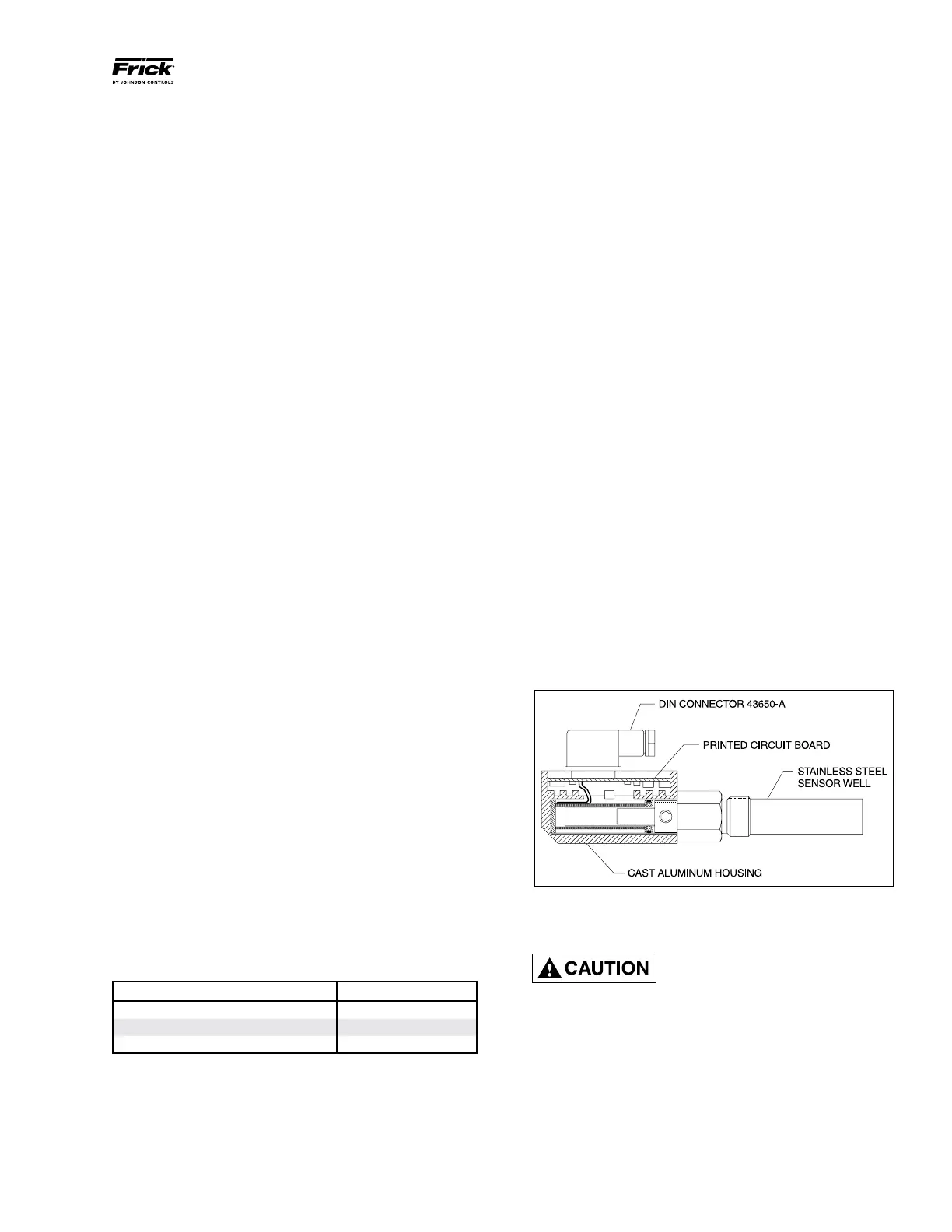

The Slide Valve Transmitter (Figure 34) is located on the

right side of the compressor (facing shaft) at the inlet end.

The linear transmitter with hermetic enclosure is based on

the inductive measuring principle. It features removable

electronics (from the sensor well) eliminating the need to

evacuate the compressor for replacement. This type of

transmitter is dedicated to volume ratio control and has no

user adjustments.

1. Shut off control power.

2. Remove DIN connector plug from transmitter.

3. Loosen set screws.

4. Remove transmitter unit.

5. Install new transmitter unit.

6. Tighten set screws.

7. Apply DIN connector plug to transmitter.

8. Turn on control power.

NOTE: For calibration of the Slide Valve unit, refer to the

Analog Calibration instructions in publication 090-020 O.

Figure 34 - Slide Valve Transmitter

TEMPERATURE SENSOR REPLACEMENT

This device is static sensitive. Please

follow proper ESD procedures when

handling.

1. Shut off control power.

2.

Remove DIN connector plug from transmitter. See Figure 35.

3. Unscrew knurled ring and remove transmitter unit.

4. Apply thermal compound to new sensor assembly, insert

into thermal well, and tighten knurled ring.

5. Apply DIN connector plug to transmitter.

6. Turn on control power.

Loading...

Loading...