RXF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

070.410-IOM (JAN 12)

Page 12

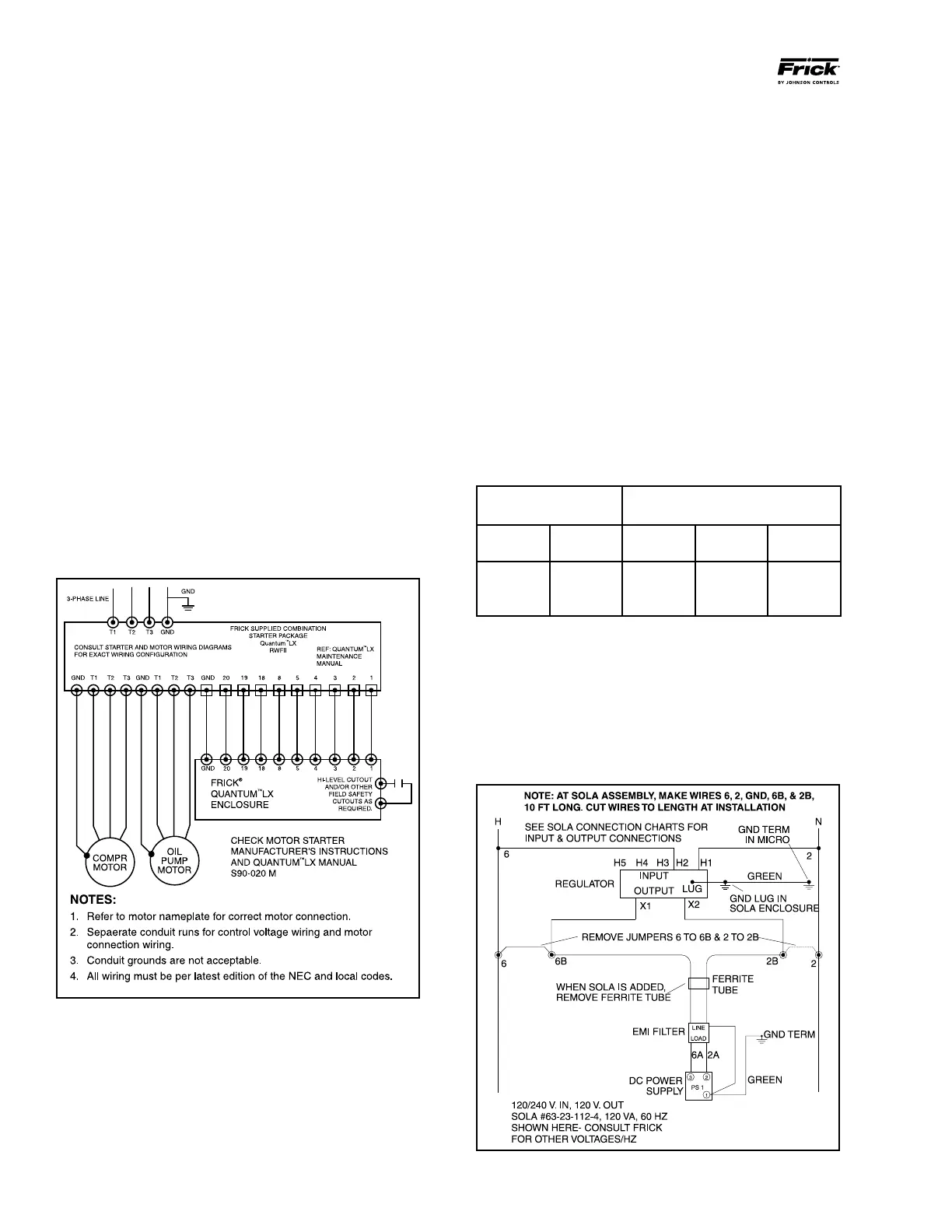

Motor starter and interlock wiring require ments are shown

in the diagram, Figure 12. All of the equipment shown is sup-

plied by the installer unless a starter package is pur chased

separately from Frick. Starter packages should consist of:

1. The compressor motor starter of the specied horse-

power and voltage for the starting method specified

(across-the-line, autotransformer, wye-delta or solid-state).

NOTE: If starting methods other than across-the-line are

desired, a motor/compres sor torque analysis must be done

to ensure sufcient starting torque is available. Contact

Frick if assist ance is required.

2. If specied, the starter package can be sup plied as a com-

bination starter with circuit breaker disconnect. How ever,

the motor overcurrent protection/discon nec tion device can

be applied by others, usually as a part of an electrical power

distribution board.

3. A 3.0 KVA control power transformer (CPT) to supply 120

volt control power to the control system and separator oil

heaters is included. If environmental conditions require more

than 2000 watts of heat, an appro priately oversized control

trans former will be required.

4. One normally open compressor motor starter auxiliary

contact should be supplied and wired as shown on the starter

package wiring diagram. In addition, the compressor starter

coil and the CPT secondaries should be wired as shown on

the starter package wiring diagram, Figure 12.

Figure 13 - Point-to-Point Wiring Diagram

5. The compressor motor Current Transformer (CT) can be

installed on any one phase of the compressor leads. NOTE:

the CT must see all the current on any one phase, there-

fore in wye-delta applications BOTH leads of any one

phase must pass through the CT.

CURRENT TRANSFORMER SIZE

Calculate (CT) size using the following formula where SF is

Service Factor and FLA is Full Load Amps of the Motor.

FLA x SF x 1.1

(round up to the next hundred)

Example: FLA = 379; Service Factor = 1.15

379 x 1.15 x 1.1 = 479

Use a 500:5 CT

DO NOT use undersized current transformers since the panel

will not be capable of reading potential current. If the CT is

higher than calculated, enter it's value for [CT Factor] on the

panel. The unit can operate with a CT one size larger than

calculated, however, replace with the proper size ASAP. DO

NOT operate unit with a CT more than one size larger

than recommended.

MINI MUM BURDEN RATINGS

The following table gives the minimum CT burden ratings.

This is a function of the distance between the motor starting

package and the compressor unit.

B-0.1 2.5 15 ft 25 ft 40 ft

B-0.2 5 35 ft 55 ft 88 ft

B-0.5 12.5 93 ft 148 ft 236 ft

NOTE: Do not install a compressor HAND/OFF/AUTO

switch in the starter package as this would bypass the

compressor safety devices.

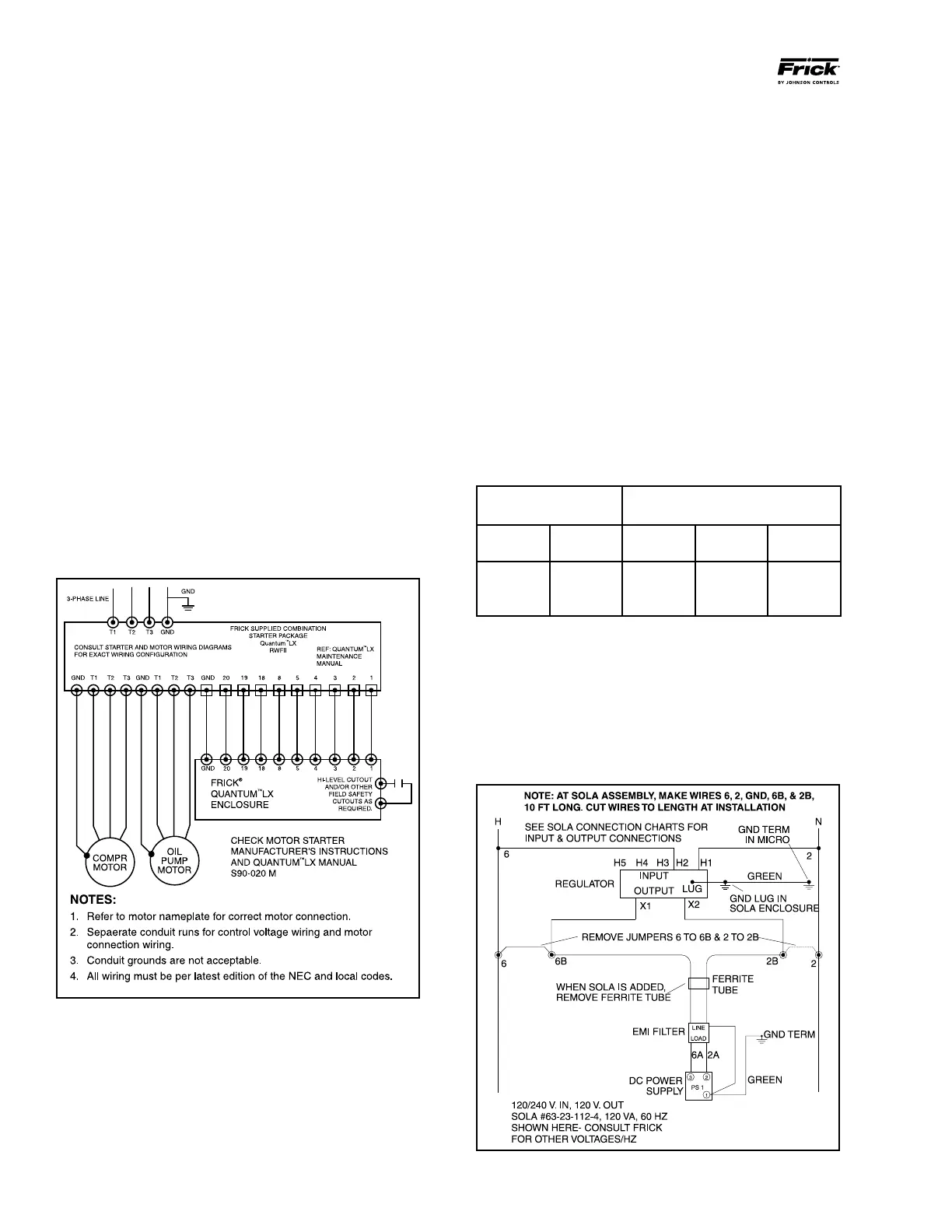

CONTROL POWER REGULATOR

Compressor units that will be used in areas that suffer brown-

outs and other signicant power uctuations can be supplied

with a control power regulator. See Figure 14, Recommended

Regulator Installation.

Figure 14 - Recommended Regulator Installation

Loading...

Loading...