5808011-JIM-A-0320

Johnson Controls Ducted Systems 37

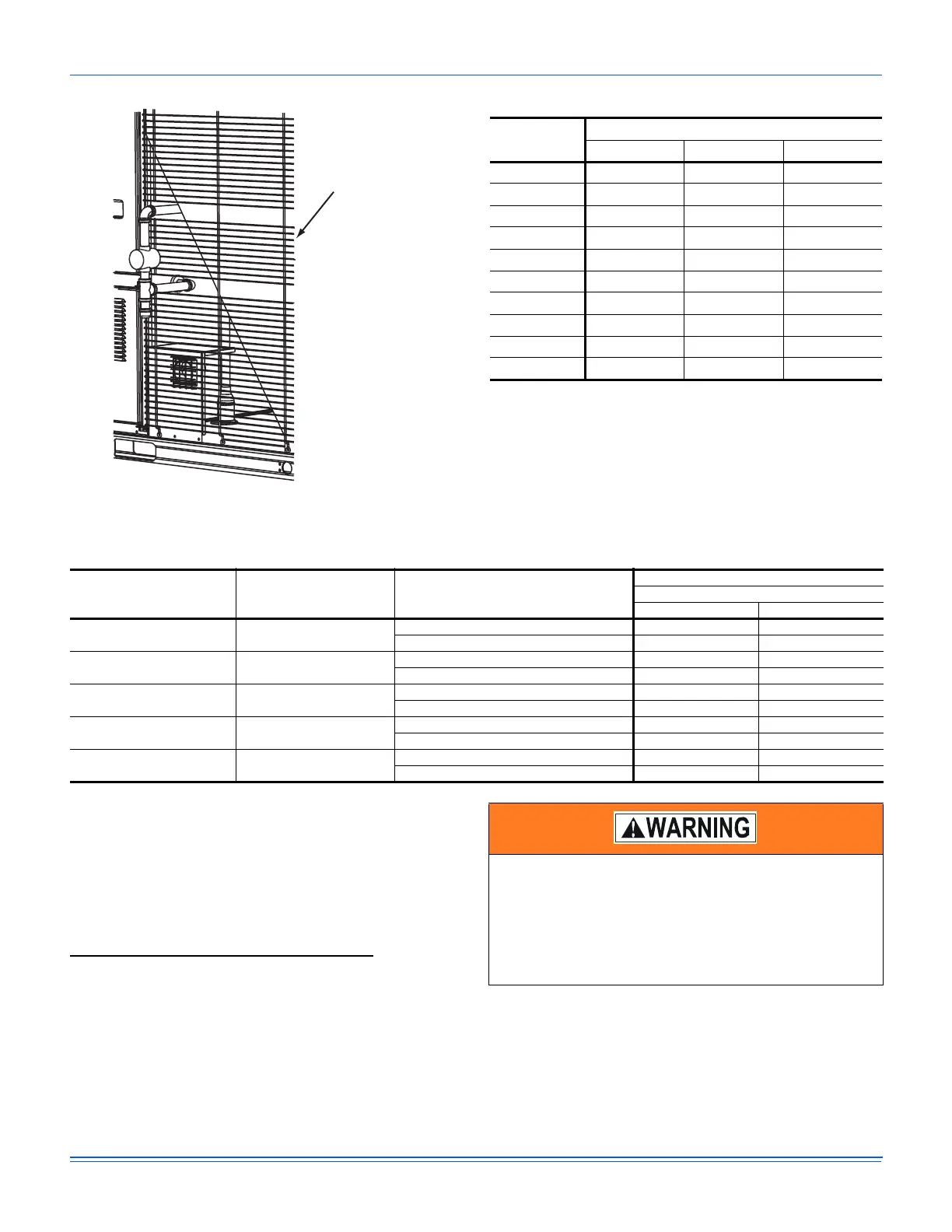

Figure 23: Bottom entry gas piping

Note: Maximum capacity of pipe in cubic feet of gas per hour

based upon a pressure drop of 0.3 inch W.C. and 0.6

specific gravity gas.

Note: There may be a local gas utility requirement specifying a

minimum diameter for gas piping. All units require a 3/4

inch pipe connection at the entrance fitting. Line should

not be sized smaller than the entrance fitting size.

Gas connection

Route the gas supply line within the space and roof curb with the

exit through the unit’s basepan. See Figures 22 and 23 for the

gas piping inlet location. Typical supply piping arrangements are

shown in Figures 22 and 23. All pipe nipples, fittings, and the gas

cock are field supplied or may be purchased in the Ducted

Systems accessory kit #1GP0405.

Apply the following gas piping recommendations.

• You must install a drip leg and a ground joint union in the

gas piping.

• When required by local codes, install a manual shut-off

valve outside of the unit.

• Use wrought iron or steel pipe for all gas lines. Apply pipe

dope sparingly to male threads only.

• Clean all piping of dirt and scale. Hammer on the outside

of the pipe and blow out loose particles. Before initial

start-up, make sure that all gas lines external to the unit

are purged of air.

• The gas supply must be a separate line and installed in

accordance with all safety codes as prescribed under

Limitations.

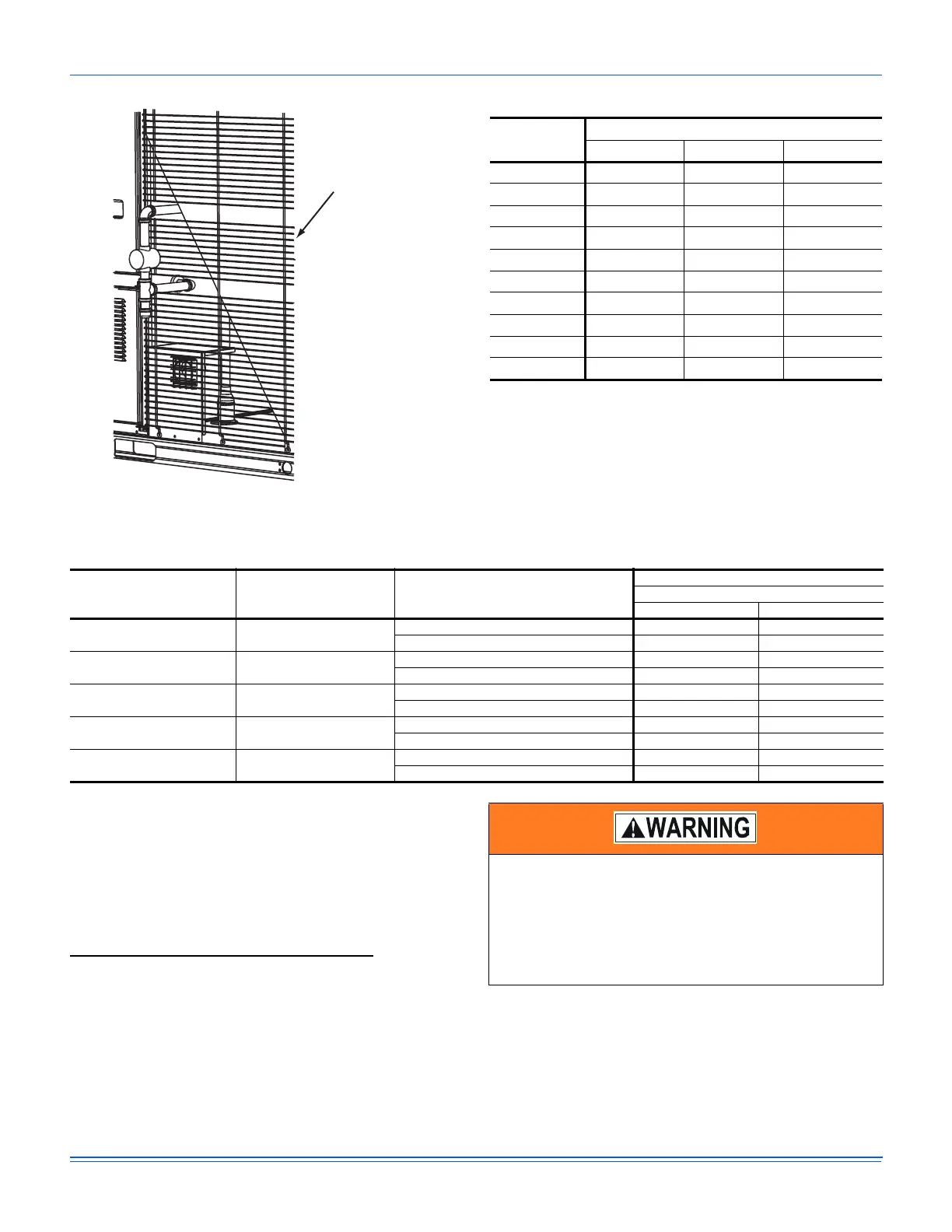

Table 14: Gas pipe sizing - capacity of pipe

Length of

pipe (ft.)

Nominal iron pipe size

3/4 in. 1 in. 1-1/4 in.

10 278 520 1050

20 190 350 730

30 152 285 590

40 130 245 500

50 115 215 440

60 105 195 400

70 96 180 370

80 90 170 350

90 84 160 320

100 79 150 305

Table 15: Gas heat minimum supply air

Size (tons) Model Heat size

Supply air (CFM)

Heating

Minimum Maximum

J06

(6.5)

ZB

N12 1950 3250

N18 1950 3250

J07

(7.5)

ZB

N12 2250 3750

N18 2250 3750

J08

(8.5)

ZB

N12 2550 4250

N18 2550 4250

J10

(10)

ZB

N18 3000 5000

N24 3000 5000

J12

(12.5)

ZB

N18 3750 6250

N24 3750 6250

Natural gas may contain some propane. Propane is an

excellent solvent and will quickly dissolve white lead and

most standard commercial compounds. A special pipe

dope must be used when assembling wrought iron or

steel pipe. Shellac based compounds such as Gaskolac

or Stalastic, and compounds such as Rectorseal #5,

Clydes’s or John Crane may be used.

Loading...

Loading...