WARNING

This is not a backseating valve. The service access

port has a valve core. Opening or closing valve does

not close service access port. If the valve stem is

backed out past the chamfered retaining wall, the

O-ring can be damaged causing leakage or system

pressure could force the valve stem out of the valve

body possibly causing personal injury.

The valve can be opened by removing the service valve

cap and fully inserting a hex wrench into the stem and

backing out counter-clockwise until valve stem just

touches the chamfered retaining wall.

Connecting the refrigerant lines

1. Remove the cap and Schrader core from both the

liquid and vapor service valve service ports at the

outdoor unit. Connect low pressure nitrogen to the

liquid line service port.

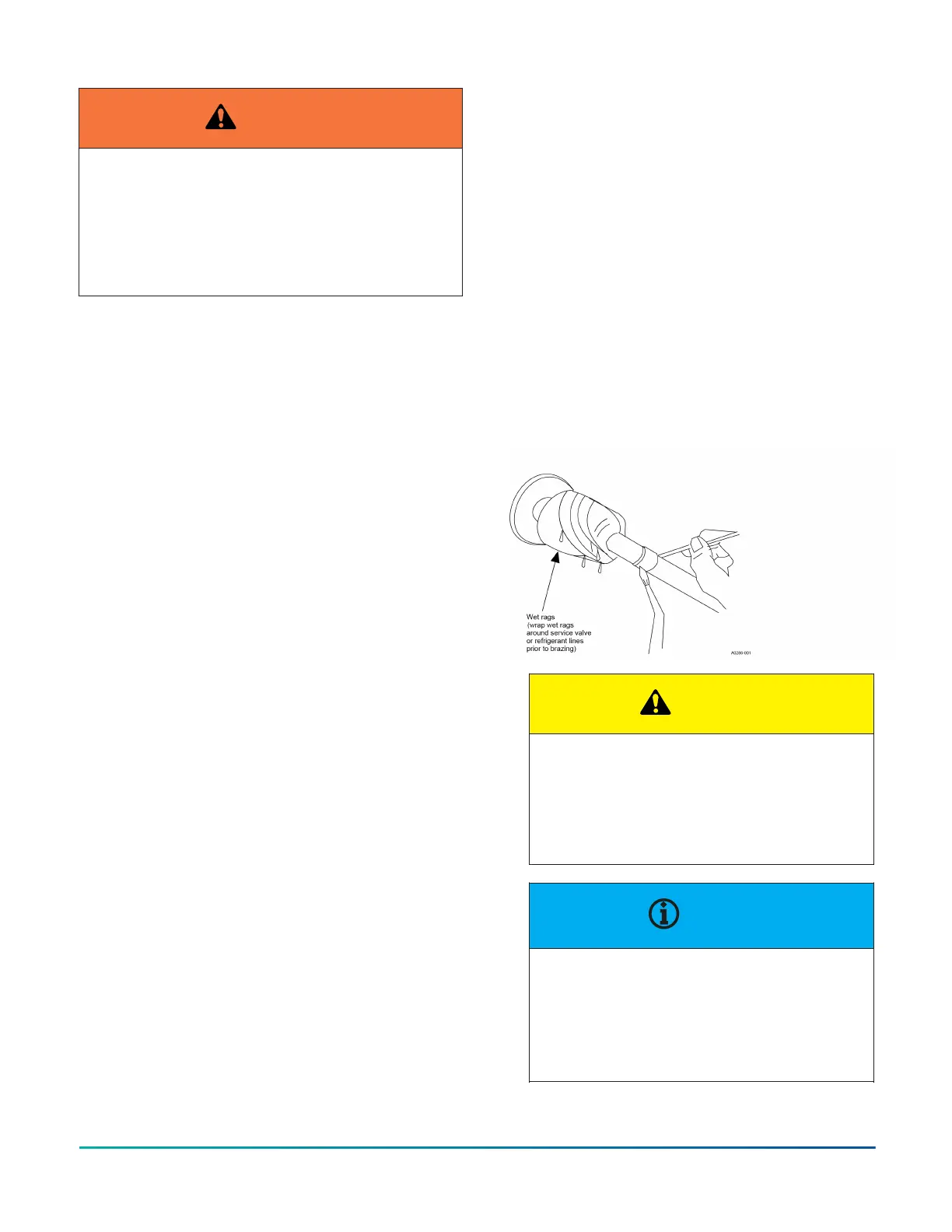

2. Braze the liquid line to the liquid valve at the

outdoor unit. Be sure to wrap the valve body with a

wet rag. Allow the nitrogen to continue flowing.

3. Carefully remove the plugs from the indoor liquid

and vapor connections at the indoor coil.

4. Braze the liquid line to the indoor coil liquid

connection. Nitrogen should be flowing through

the indoor coil.

5. Slide the grommet away from the vapor connection

at the indoor coil. Braze the vapor line to the

indoor coil vapor connection. After the connection

has cooled, slide the grommet back into original

position.

6. Protect the vapor valve with a wet rag and braze

the vapor line connection to the outdoor unit.

The nitrogen flow should be exiting the system

from the vapor service port connection. After this

connection has cooled, remove the nitrogen source

from the liquid fitting service port.

7. Replace the Schrader core in the liquid and vapor

valves.

8. See Indoor expansion device.

9. Leak test all refrigerant piping connections

including the service port flare caps to be sure they

are leak tight. Do not over-tighten (between 40 in.

lb and 60 in. lb maximum).

10. Evacuate the vapor line, indoor coil, and liquid line

to 500 microns or less. See SECTION V: Evacuation.

11. Release the refrigerant charge into the system.

Open the liquid line service valve first. Once system

pressures have equalized, open the vapor line

service valve. Valves can be opened by removing

the valve caps and turn the valve counterclockwise

using a hex head wrench. If the service valve is a

ball valve, use an adjustable end wrench to turn

valve stem one-quarter turn counterclockwise

to open. Do not overturn or the valve stem may

break or become damaged. See Precautions during

brazing of service valve.

12. Replace service valve cap finger tight, then tighten

an additional 1/12 turn (1/2 hex flat). Cap must be

replaced to prevent leaks.

13. See System charge for checking and recording

system charge.

Example:

Figure 5: Heat protection

CAUTION

Do not install any coil in a furnace which is to

be operated during the heating season without

attaching the refrigerant lines to the coil. The

coil is under pressure which must be released

to prevent excessive pressure build-up and

possible coil damage.

NOTICE

Line set and indoor coil can be pressurized to

250 psig with dry nitrogen and leak tested with

a bubble type leak detector. Then release the

nitrogen charge.

Do not use the system refrigerant in the outdoor

unit to purge or leak test.

R-410A Outdoor Split-System Heat Pump Installation Manual - YH2E / THE2 / RHP143 Series 11

Johnson Controls Ducted Systems

Loading...

Loading...