the control allows another defrost cycle when needed. The

timer is based on accumulated compressor runtime.

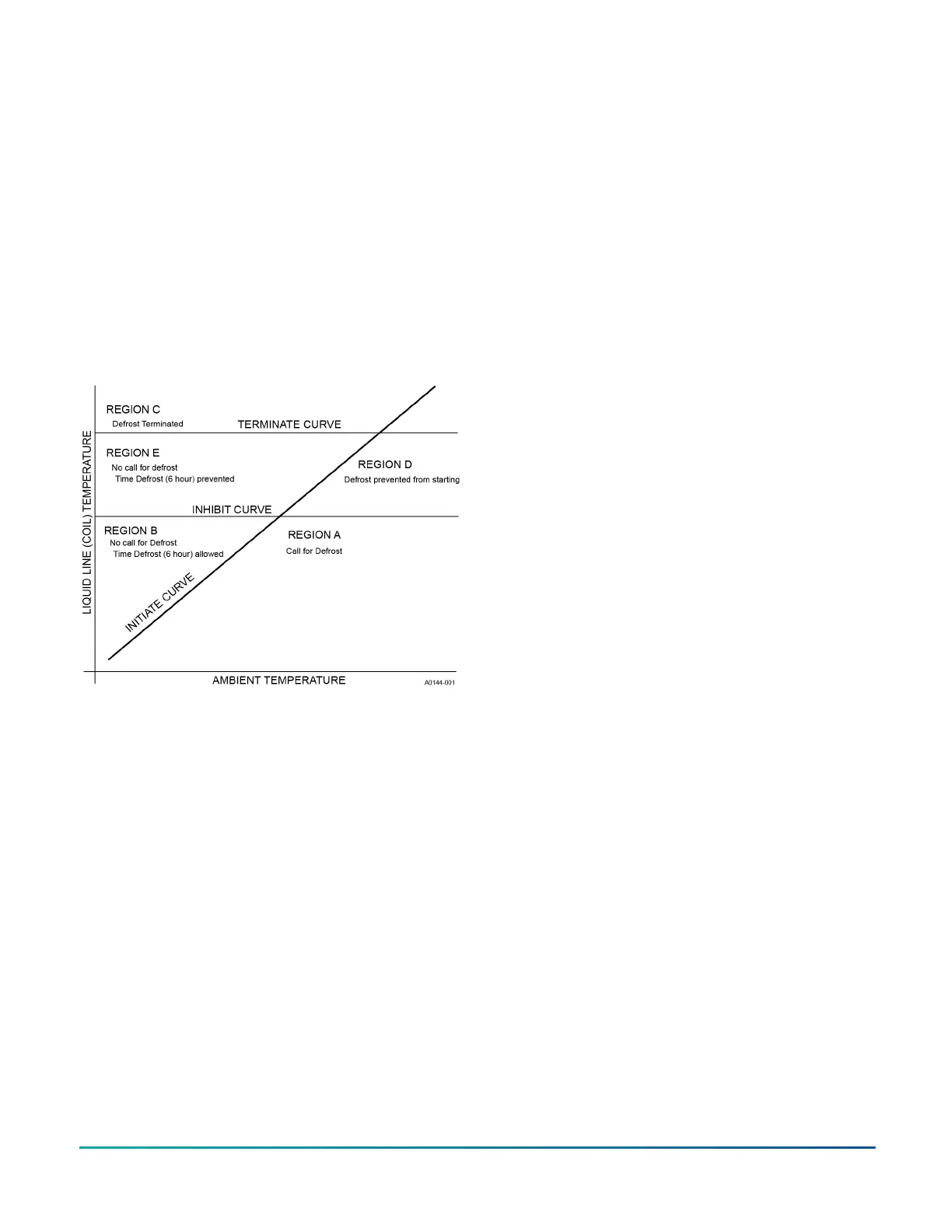

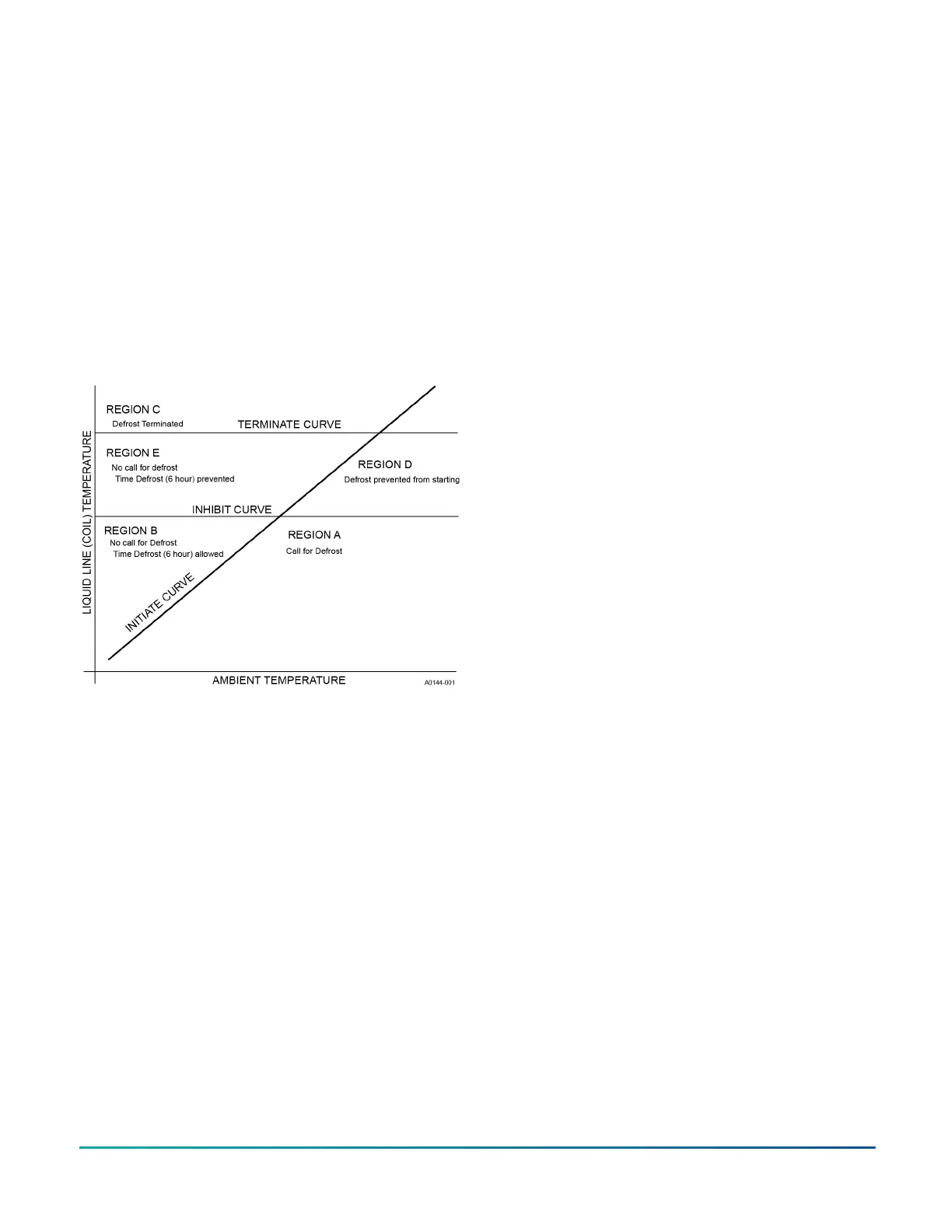

Defrost termination

The control terminates the defrost cycle immediately

after the liquid line temperature reaches the terminate

temperature or after 14 min of defrost operation. See

Figure 23.

The control does the following to terminate a defrost

cycle:

• Energize the outdoor fan.

• De-energize the reversing valve.

• De-energize the auxiliary heat output through the W

out terminal.

• Reset and restart the 40 min defrost inhibit timer.

Figure 23: Defrost operation curves

Cooling operation

During cooling operation, the control receives thermostat

signals at the Y (Y + Y2 for 2nd stage), and O input

terminals. The control energizes the M (M + M2 for

2nd stage) compressor output terminal. This signal

energizes the coil of the compressor contactor causing

the compressor to operate. The control also delivers

power to the COND FAN terminals causing the outdoor

fan to operate. The control energizes the REV VALVE

terminal with 24 VAC to switch the reversing valve.

Heating operation

During normal heating mode, the control receives a

thermostat signal at the Y (Y + Y2 for 2nd stage) input

terminal. The control energizes the M (M + M2 for

2nd stage) compressor output terminal. This signal

energizes the coil of the compressor contactor causing

the compressor to operate. The control also delivers

power to the COND FAN terminals causing the outdoor

fan to operate. The reversing valve is not energized in

heating mode.

In low ambient conditions (<40°F) the control energizes

M2 and Y2 out, forcing second stage operation for the

remainder of the call.

Emergency heat

When the thermostat calls for emergency heat operation

(W signal without a Y signal), the control energizes the

Wout terminal immediately.

Pressure switch fault and lockout

The heat pump is equipped with a high pressure switch

and low pressure switch that connect to the control at

the pressure switch terminals. If the high pressure switch

input opens for more than 40 ms, the control de-energizes

the compressor. If the switch is closed and a thermostat

call for compressor operation is present, the control

applies the 5 min anti-short-cycle delay timer and starts

the compressor when the timer expires.

If the low pressure switch opens for 5 s under conditions

when the control is not ignoring the low pressure switch

input, the control will enter a low pressure switch fault.

The control ignores the low pressure switch input during

the following conditions:

• Defrost operation

• The first 120 s of compressor operation

• 120 s following the completion of a defrost cycle

• When the outdoor ambient temperature is below 5

°F

When the compressor starts following a switch fault,

the control starts a 6 h timer based on accumulated

compressor runtime. If the control senses another

opening of the switch before the timer expires, it causes a

soft lockout condition. The second opening of the switch

must be greater than 160 ms for the lockout to occur. If

the second opening is between 40 ms and 160 ms, the

control de-energizes the compressor but does not cause

a soft lockout condition. If the control does not sense a

second switch opening before the 6 h timer expires, the

timer and counter reset.

During the soft lockout mode, the control de-energizes

the compressor and energizes the LED output with the

appropriate flash code.

The control resets the soft lockout condition when any of

the following occur after removal of the fault condition:

• Power is cycled to the R or Y inputs of the control.

This causes the soft lockout condition to be reset

when the thermostat is satisfied or when the

thermostat is set to SYSTEM OFF and back to HEAT or

COOL mode.

• The TEST terminals short for more than 2 s.

When the soft lockout condition is reset, the control stops

displaying the fault code and responds to thermostat

inputs normally.

Instructing the owner

Assist the owner with processing warranty cards or online

registration. Review the User’s Information Manual, and

provide a copy to the owner and guidance on correct

operation and maintenance. Instruct the owner or the

operator how to start, stop, and adjust the temperature

setting.

When applicable, instruct the owner that the compressor

is equipped with a crankcase heater to prevent the

migration of refrigerant to the compressor during the

R-410A Outdoor Split-System Heat Pump Installation Manual - YH2E / THE2 / RHP143 Series 37

Johnson Controls Ducted Systems

Loading...

Loading...