General

The outdoor units are designed to be connected to a

matching indoor coil with sweat connect lines. Sweat

connect units are factory charged with refrigerant for

a nominal sized matching indoor coil plus 15 ft of field-

supplied lines.

Matching indoor coils can be used with a thermostatic

expansion valve (TXV). Refer to the Tabular Data Sheet or to

the Technical Guide for the proper selection.

Safety

This is a safety alert symbol. When you see this

symbol on labels or in manuals, be alert to the

potential for personal injury.

Understand and pay particular attention to the signal

words DANGER, WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation,

which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation,

which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation,

which, if not avoided may result in minor or moderate

injury. It is also used to alert against unsafe practices and

hazards involving only property damage.

WARNING

Improper installation may create a condition where

the operation of the product could cause personal

injury or property damage. Improper installation,

adjustment, alteration, service, or maintenance can

cause injury or property damage. Refer to this manual

for assistance. For additional information, consult a

qualified contractor, installer, or service agency.

CAUTION

This product must be installed in strict compliance

with the enclosed installation instructions and any

applicable local, state, and national codes including

but not limited to building, electrical, and mechanical

codes.

CAUTION

R-410A systems operate at higher pressures than

R-22 systems. Do not use R-22 service equipment

or components on R-410A equipment. Service

equipment must be rated for R-410A.

Inspection

As soon as a unit is received, it must be inspected for

possible damage during transit. If damage is evident,

the extent of the damage must be noted on the carrier’s

delivery receipt. A separate request for inspection by

the carrier’s agent must be made in writing. See Local

Distributor for more information.

Requirements for installing/servicing

R-410A equipment

• Gauge sets, hoses, refrigerant containers, and

recovery system must be designed to handle the POE

type oils, and the higher pressures of R-410A.

• Manifold sets should be high side and low side with

low side retard.

• All hoses must have a 700 psig service pressure

rating.

• Leak detectors should be designed to detect HFC

refrigerant.

• Recovery equipment (including refrigerant recovery

containers) must be specifically designed to handle

R-410A.

• Do not use an R-22 TXV.

Limitations

The unit must be installed in accordance with all National,

State and Local Safety Codes and the limitations listed

below:

• Limitations for the indoor unit, coil, and appropriate

accessories must also be observed.

• The outdoor unit must not be installed with any

duct work in the air stream. The outdoor fan is the

propeller type and is not designed to operate against

any additional external static pressure.

• The maximum and minimum conditions for

operation must be observed to ensure a system that

will give maximum performance and service life.

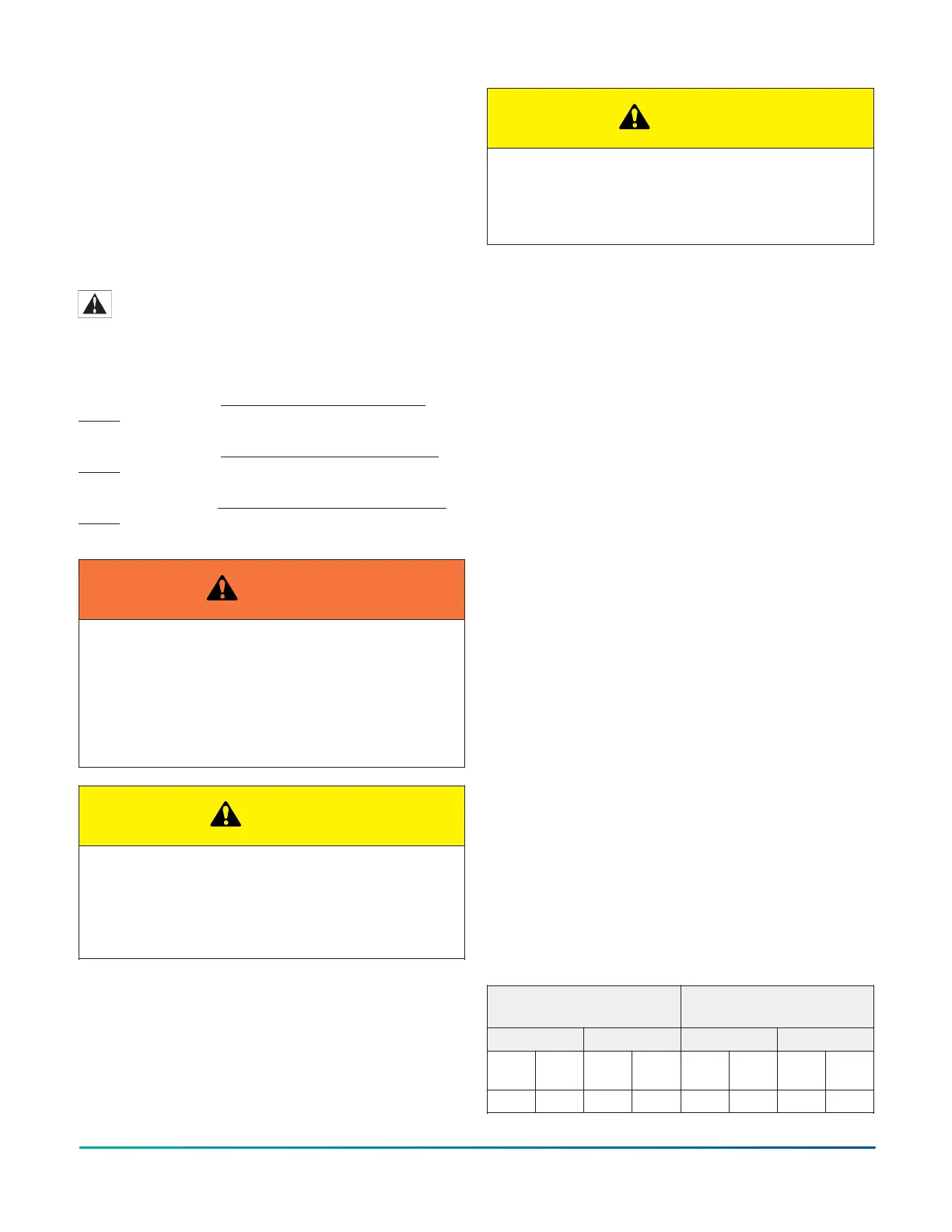

Table 1: Maximum/minimum operating limit

conditions

Air temperature at

outdoor coil °F

Air temperature at indoor

coil °F

Minimum Maximum Minimum Maximum

DB

cool

DB

heat

DB

cool

DB

heat

WB

cool

DB

heat

WB

cool

DB

heat

55 0 125 75 57 50 72 80

R-410A Outdoor Split-System Heat Pump Installation Manual - YH2E / THE2 / RHP143 Series 5

Johnson Controls Ducted Systems

Loading...

Loading...