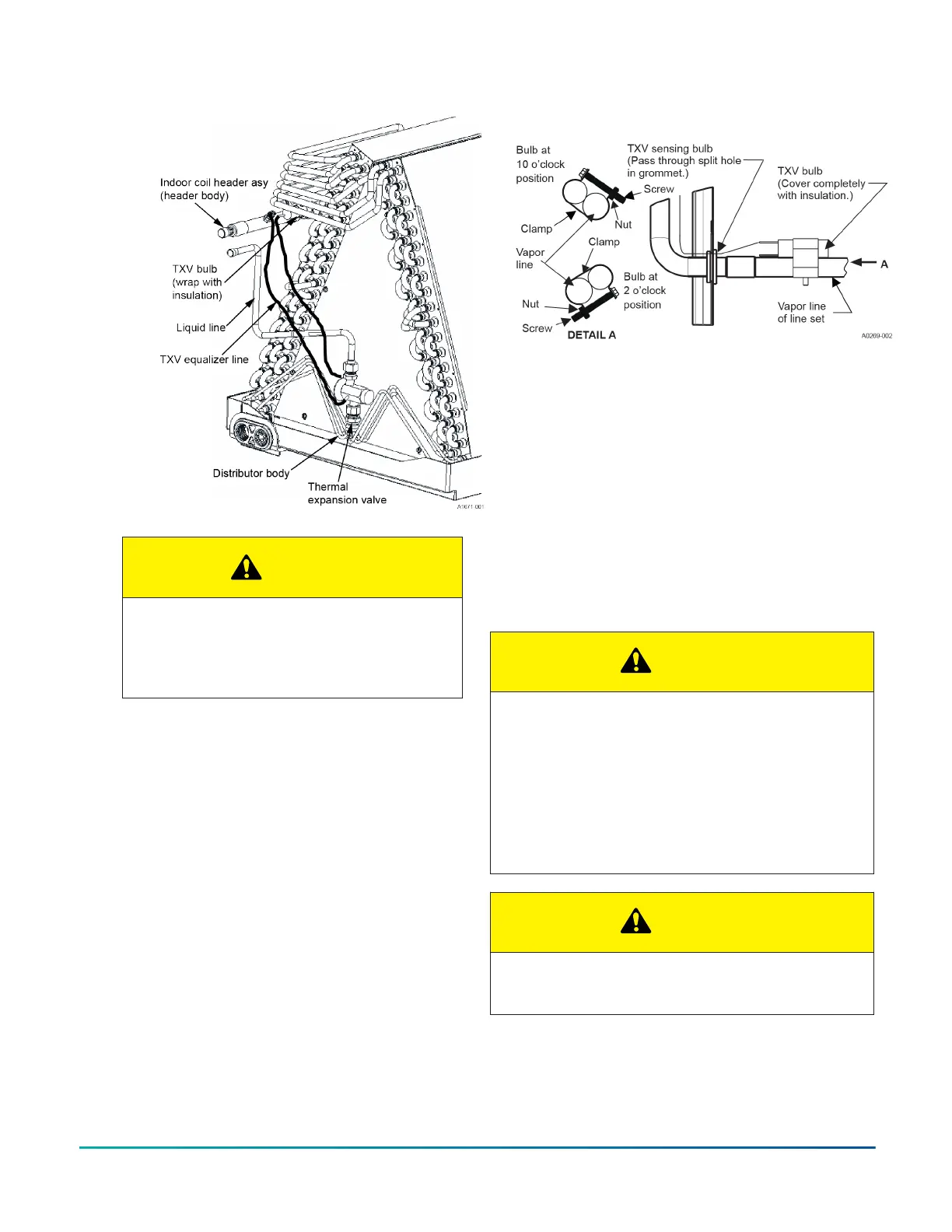

Figure 7: TXV bulb and equalizer line installations

CAUTION

In all cases, mount the TXV bulb after vapor

line is brazed and has had sufficient time to

cool. Failure to use suction line grommet may

result in premature TXV failure.

7. If the indoor coil is an A coil, skip to Step 8. If not,

pass the TXV temperature sensing bulb through

the suction line split grommet in the access panel.

8. Install the TXV bulb to the vapor line using the bulb

clamps furnished with the TXV assembly. Ensure

the bulb is making maximum contact. See Figure 7

and Figure 8.

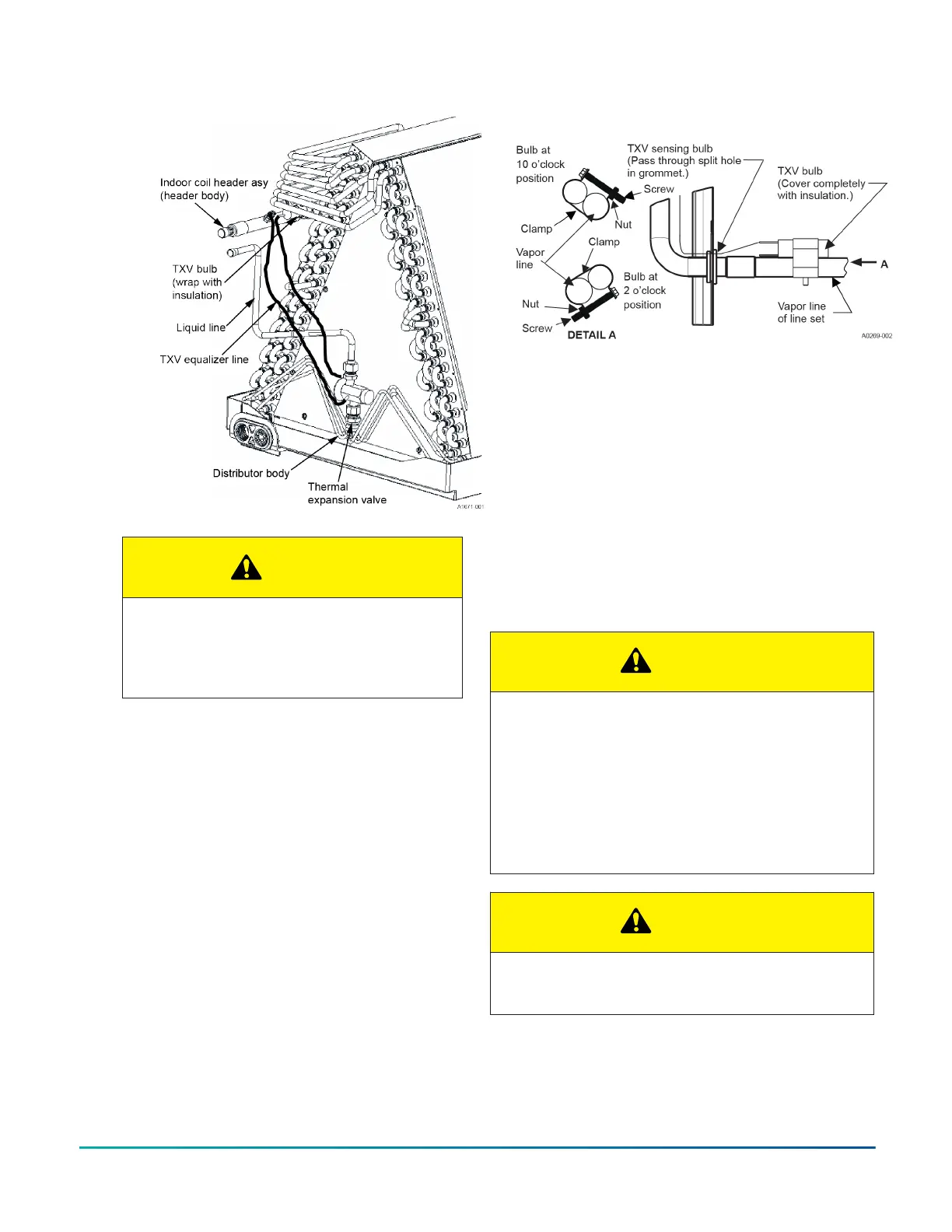

a. If possible, install the temperature bulb on

a horizontal run of the vapor line. Ensure

that the bulb is installed at a 10 o’clock or 2

o’clock position. See Figure 8.

b. If bulb installation is made on a vertical run,

ensure that the bulb is a minimum of 8 in.

(20.3 cm) away from the elbow coming out

of the coil. Position the bulb with the tail of

the bulb at the top, so that the bulb acts as a

reservoir.

c. Insulate the bulb using thermal insulation

provided to protect it from the effect of the

surrounding ambient temperature. Cover

completely to insulate.

9. After line set is installed, leak test the system.

Figure 8: Proper bulb location

Evacuation

It will be necessary to evacuate the system to 500 microns

or less. If a leak is suspected, leak test with dry nitrogen to

locate the leak. Repair the leak and test again.

To verify that the system has no leaks, close the valve to

the vacuum pump suction to isolate the pump and hold

the system under vacuum. Watch the micron gauge for

a few minutes. If the micron gauge indicates a steady

and continuous rise, it is an indication of a leak. If the

gauge shows a rise, then levels off after a few minutes

and remains fairly constant, it is an indication the system

is leak free but still contains moisture and may require

further evacuation if the reading is above 500 microns.

System charge

CAUTION

If a field installed device is placed in the inner-

connecting refrigerant lines that can store a significant

refrigerant charge (for example, a refrigerant mass

flow meter or a liquid receiver), the unit may not

perform as designed. If such a performance-affecting

device is installed and it is possible to check the

unit in heating mode, the unit pressures should be

confirmed in heating mode. See the heating charging

charts located in this installation manual.

CAUTION

Refrigerant charging should only be carried out by a

licensed qualified air conditioning contractor.

To ensure that the unit performs at the published levels,

it is important to determine the indoor airflow and add

refrigerant charge accordingly.

R-410A Outdoor Split-System Heat Pump Installation Manual - YH2E / THE2 / RHP143 Series 13

Johnson Controls Ducted Systems

Loading...

Loading...