(3) Instruction of Control board Interface

(4)Wiring diagram of control board

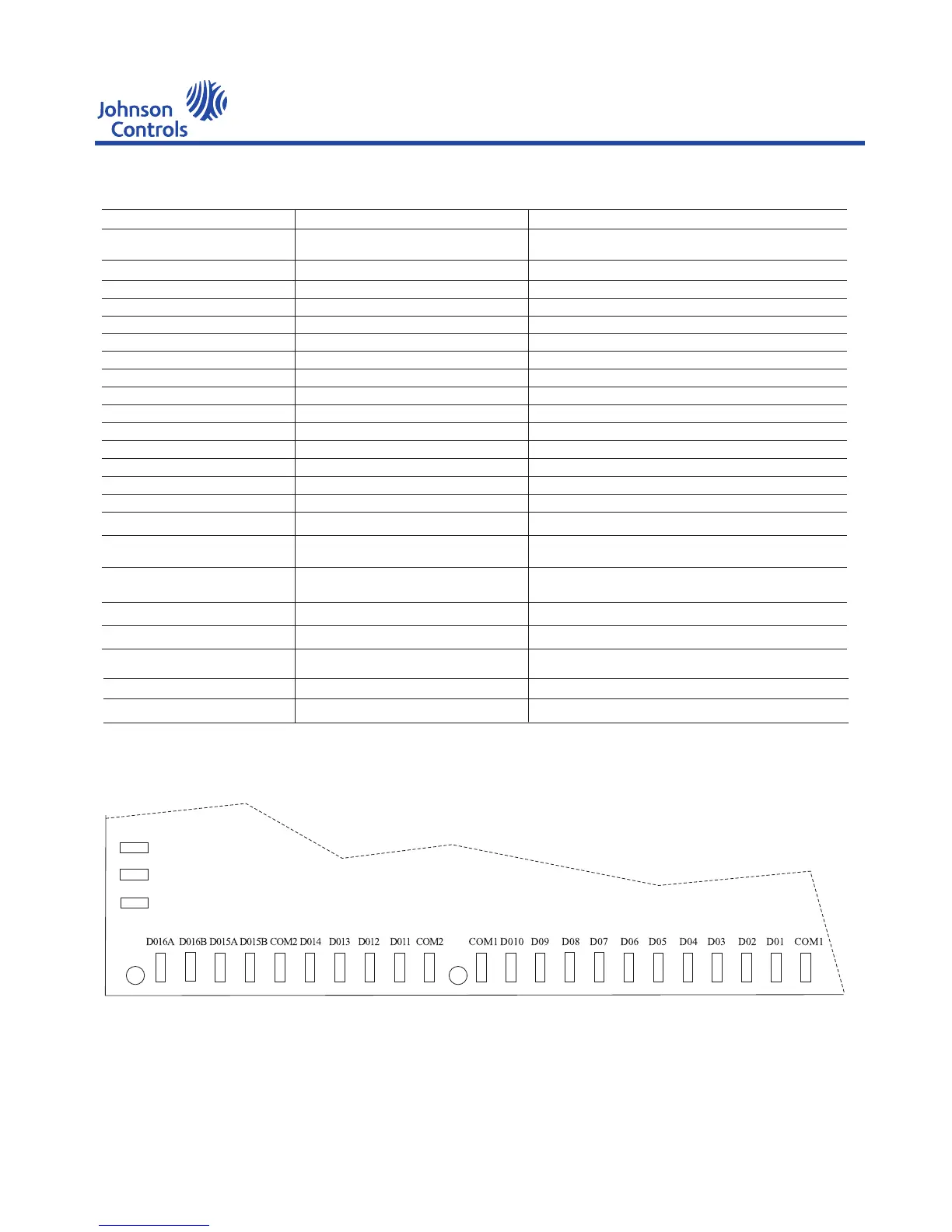

(a) Power and DO output interface diagram

Instruction

DO1-DO10 : Relay output

DO11-DO14 : Relay output

DO15A,DO15B : Bi-directional Thyristor output

L : AC220V live wire

N : Zero line

L

PE

N

Symbol

CON2(COMU)

COM

DI1–DI12

CON3

VCC

0V

AI13–AI16

+12V

AI1–AI12

CN5,CN6

COM1

COM2

DO15A,DO15B

DO16A,DO16B

L,N

PE

JP1

AI13–AI16(Alignment needle)

TEST

SW1

POWER(LED)

COM(LED)

RUN(LED)

Description

485 communication port

Common port of DI switch input

DI switch input

Blower speed adjusting interface.

+5V power with analog quantity input

Ground end of analog quantity input

Analog input

+12V power output

Analog input

Expansion output

Output common port of relay

Output common port of relay

Thyristor output

Thyristor output

Note

Connect according to the marked A, B, positive and

negative terminal of power

The two COM ports are jointed together

12 DI switch inputs in all

PG motor speed adjustment

VCC of all 6 circuit is connected

Ground end of AI13 to AI16,All connected together

4-20ma 1-5V or NTC signal input

Ordinary NTC signal input

2*4 ways TTL level output

Common port of DO1 - DO10

Common port of DO11 -Do14

220VAC/50Hz

Connect or break the load resistance, operate according to

the above diagram

Selection of AI13-AI16 analog quantity divided resistance,

the operating method refers to the panel

For downloading programs

Setting the main board address

Red, the light will be on if the power of main board is in

normal situation

Green, communication success for one time, turning over

Yellow, flash in 0.5Hz frequency

AC power input

Safety ground end

485 resistance control of

communication load

Selection of divided resistance

Test

Dial switch

Power indicating lamp

Communication indicating lamp

Running indicating lamp

COM1 : Common port of DO1-DO10 output

COM2 : Common port of DO11-DO14 output

DO16A,DO16B : Bi-directional Thyristor output

PE : Earthing

YEWS-E Water Cooling Screw Chiller/Heat Pump

22

Loading...

Loading...