8

Motor Installation

Using two people may make some parts of the following

process much easier.

1. Remove the bolts on each side of the protective casing of the

motor (A). Remove the rubber grommet near the limit switch sensor

as shown and remove the casing from the motor. Use your release

key (B) to unlock the gear again.

2. Position the mounting plate (D) loosely onto the foundation bolts

(G) and position the motor loosely onto the mounting plate. You

can place two M10 nuts (N) between them now to approximate the

motor’s nal height or simply make the appropriate allowances in

the following steps.

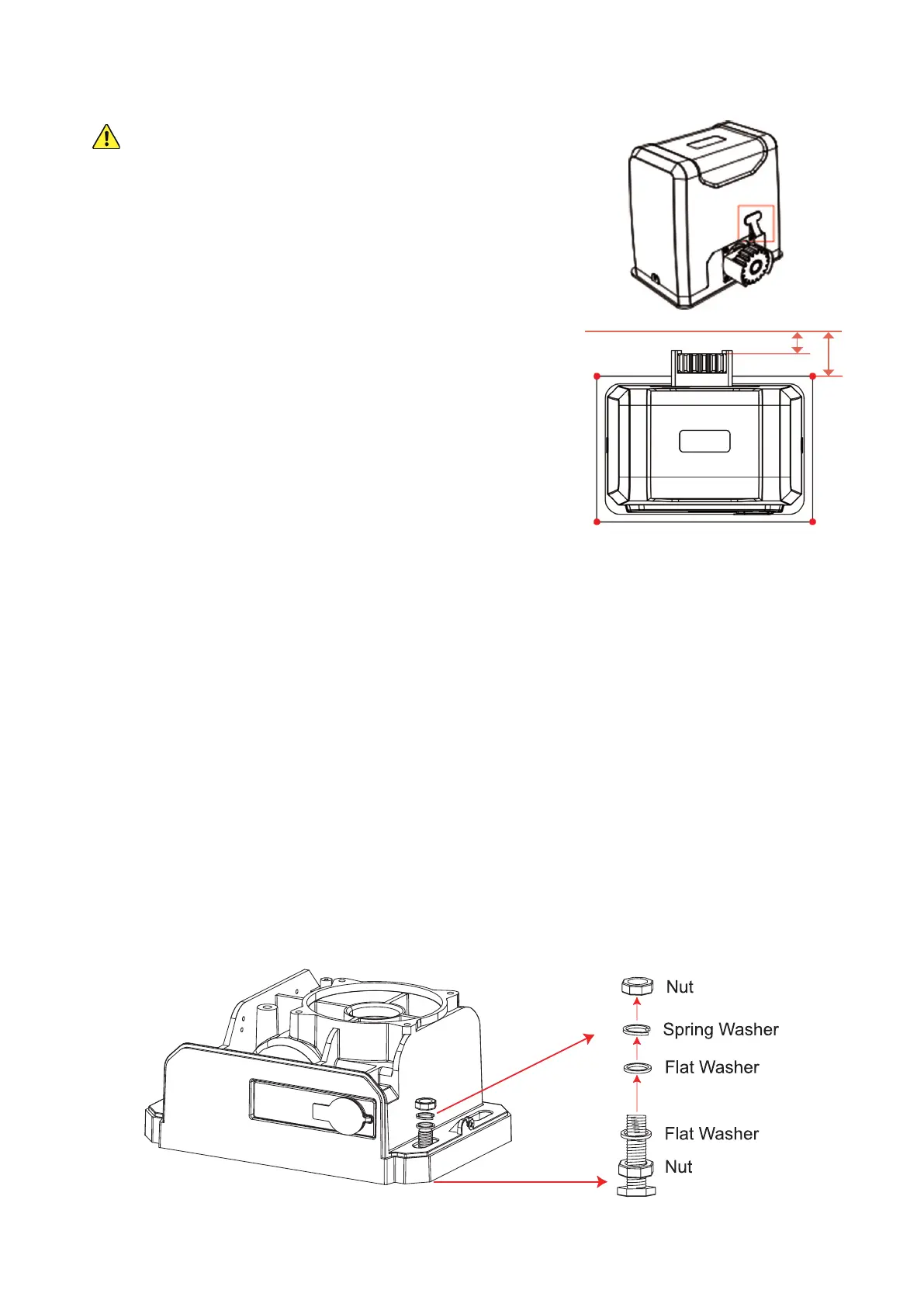

3. Position one of the Module 4 racks (E) so that it rests on top of the

motor’s main gear. Move the rack so that it is positioned properly—

completely ush against the gate—while at the same time moving

the motor as well to keep its main gear positioned properly under

the rack’s teeth. Once both rack and motor are well positioned,

mark the locations on the gate and the foundation. It should match

the diagram at the right.

4. Hold both rack and motor in place while you manually move the

gate along its entire length. The gate should be so smooth and well

aligned that the rack slides along without a problem.

Correct any alignment or binding problem with the gate until the motor and rack can be held smoothly in place

and well aligned through the gate’s entire range of motion.

5. Once the gate is completely open, conrm that there will be at least 1 foot or 30 cm between the middle of

the main gear and the far end of the gate. This will allow enough room for the limit switch and help avoid any

possibility of accidental derailment. If necessary, move the gate opener over and then repeat the positioning

and alignment steps above.

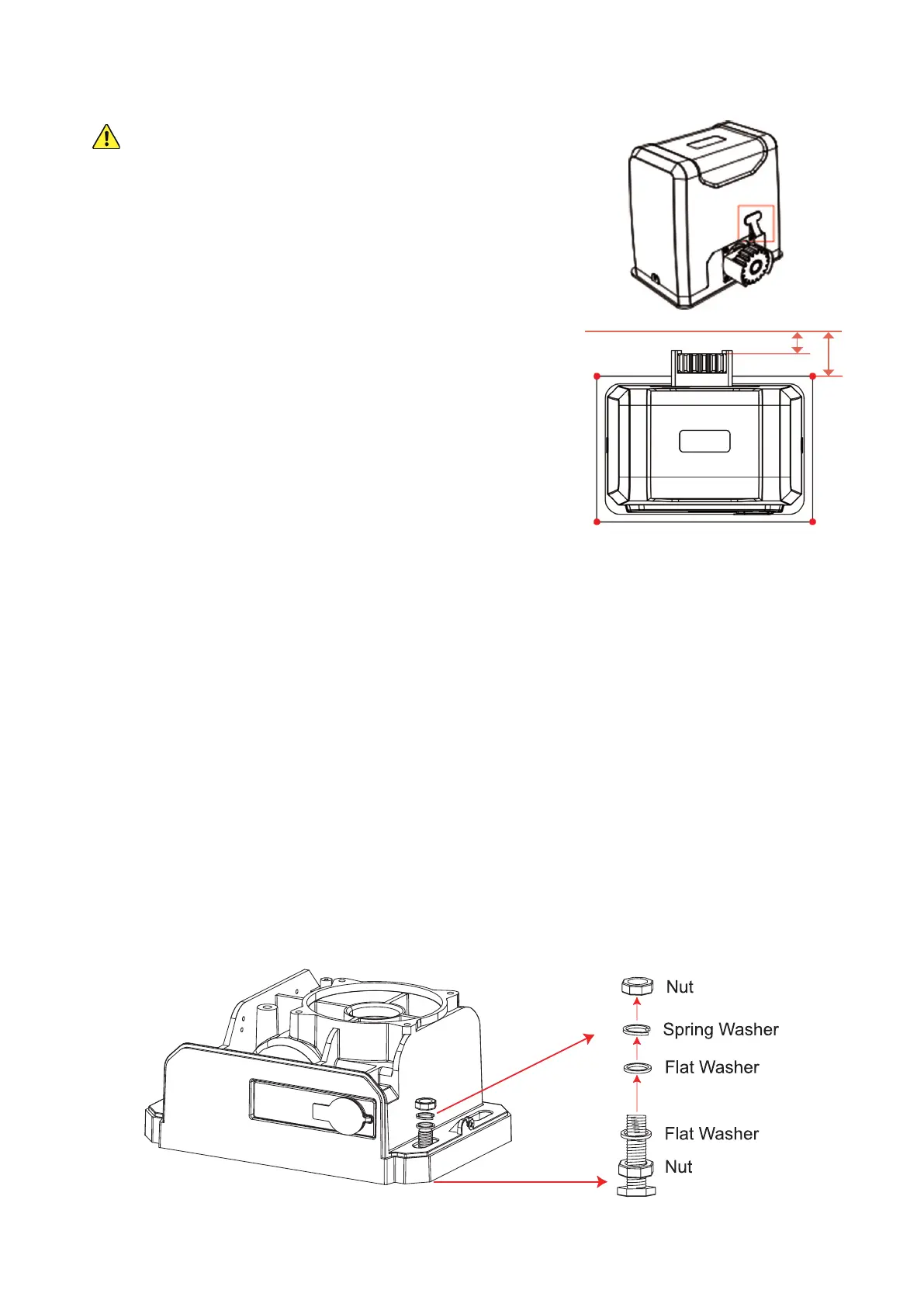

6. Once the motor is fully correctly positioned, mark everything before removing the piece of track and the motor

itself. You can hold the motor in place using only the foundation bolts and nuts—with or without the mounting

plate—but it is recommended you use the mounting plate, the foundation bolts and nuts, and the M10×50 hex

bolts (I). The additional components, along with their at (L) and spring washers (M), should give your motor a

rmer hold and give you more exibility to carefully adjust its height and keep everything completely level.

The recommended arrangement is shown below, but add or remove washers and make other adjustments as

needed so that everything is completely level, well aligned, and rmly held in place once you’re done.

A

A

17–21 mm (0.7–0.8 in.)

B

53–57 mm (2.1–2.2 in.)

B

Loading...

Loading...