– 16 –

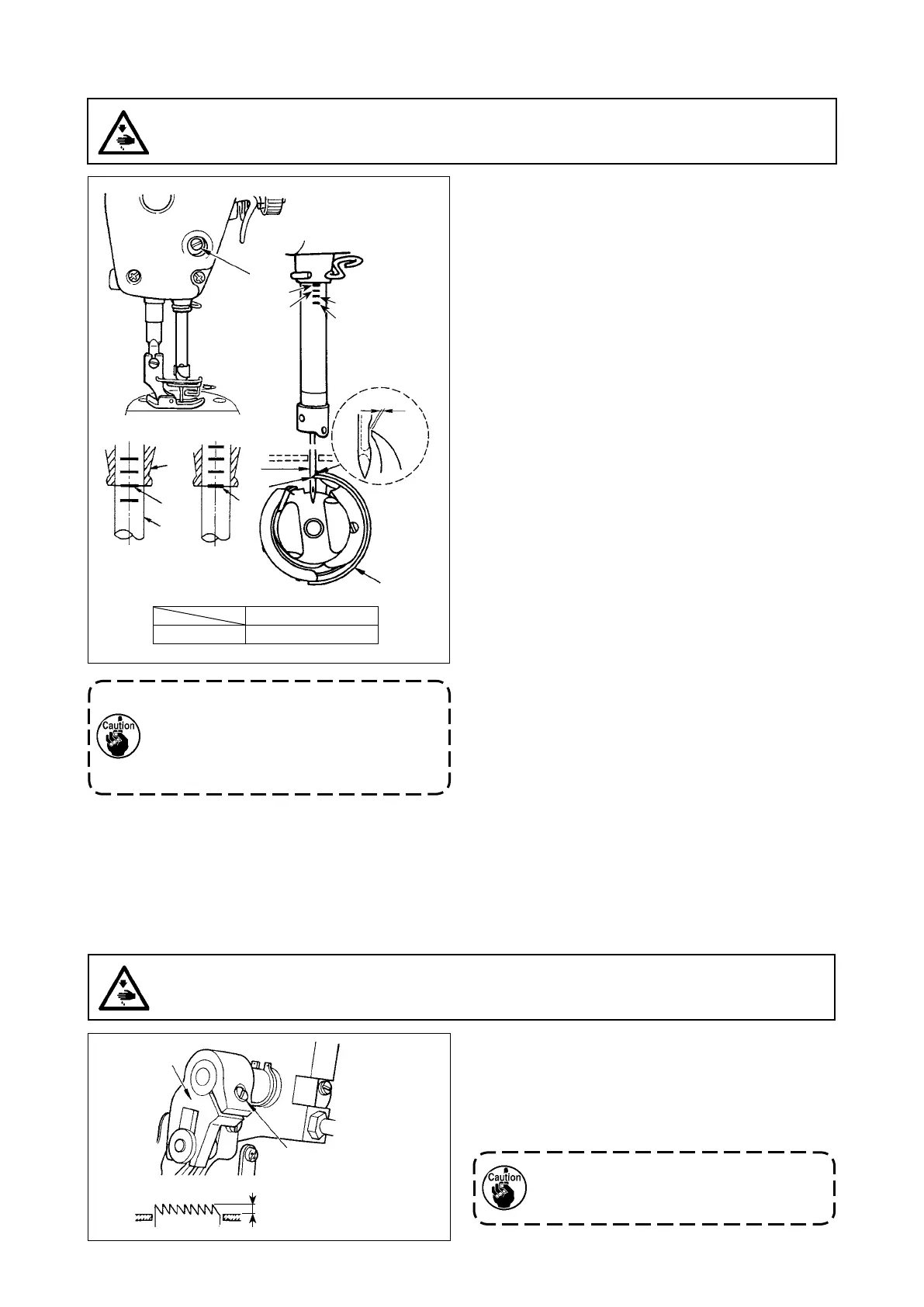

If the clearance between the blade point

of hook and the needle is smaller than the

specied value, the blade point of hook

will be damaged. If the clearance is larger,

stitch skipping will result.

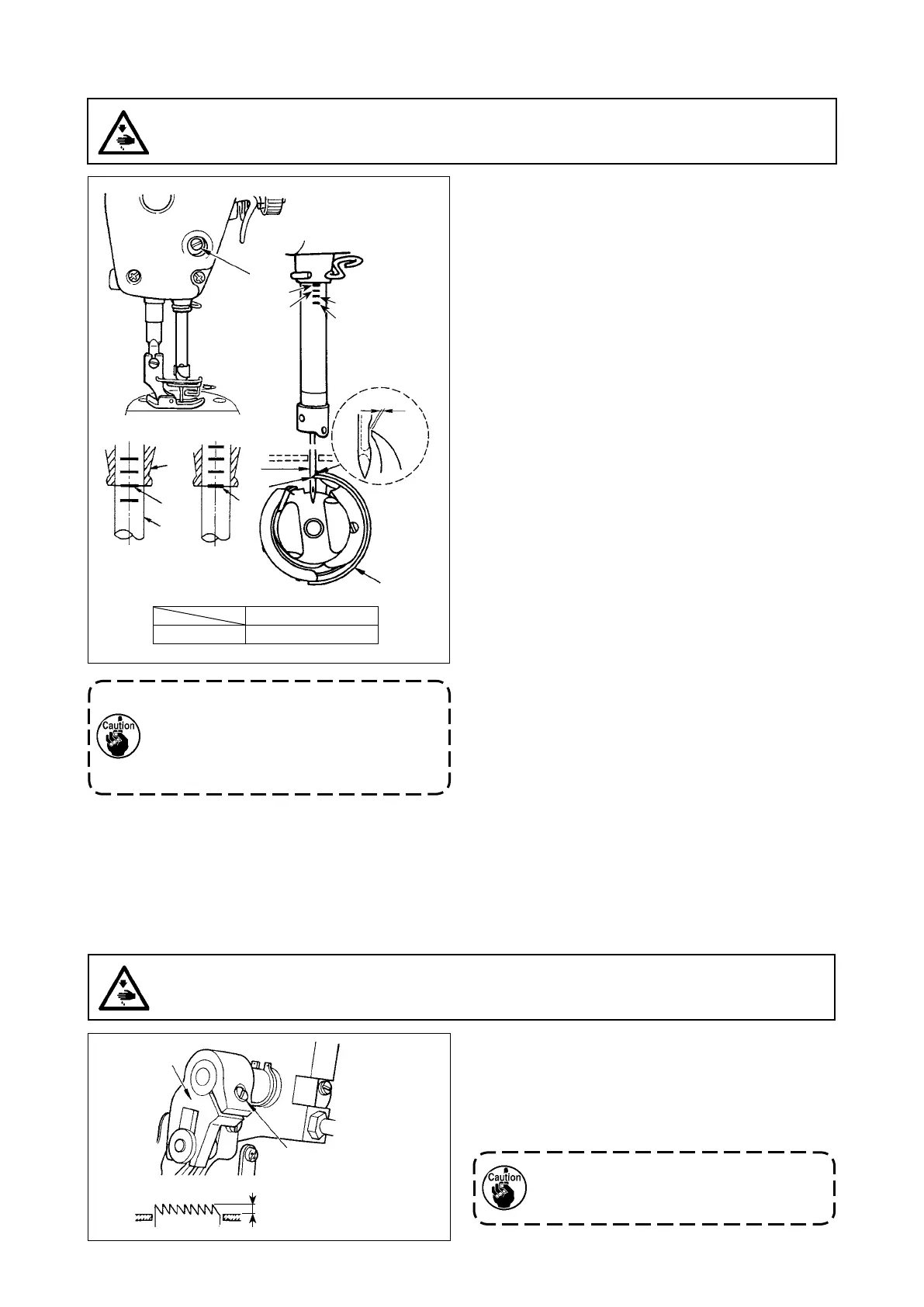

To adjust the height of the feed dog :

1) Loosen screw ❷ of crank ❶.

2) Move the feed bar up or down to make adjust-

ment.

3) Securely tighten screw ❷.

If the clamping pressure is insufcient,

the motion of the forked portion becomes

heavy.

Adjust the timing between the needle and

the hook as follows :

1) Turn the handwheel to bright the needle bar

down to the lowest point of its stroke, and loosen

setscrew ❶.

Adjusting the needle bar height.

2) [For a DB/DP needles]

Align marker line A on the needle bar ❷ with the

bottom end of the needle bar lower bushing ❸,

then tighten clamping screw ❶ of the needle bar

connection.

[For a DA needle]

Align marker line C on the needle bar ❷ with the

bottom end of the needle bar lower bushing ❸,

then tighten clamping screw ❶ of the needle bar

connection.

Adjusting position of the hook ❺.

3) [For a DB/DP needles]

Loosen three setscrews of the hook, turn the

handwheel and align marker line B on ascending

the needle bar ❷ with bottom end of the needle

bar lower bushing ❸.

[For a DA needle]

Loosen three setscrews of the hook, turn the

handwheel and align marker line D on ascending

the needle bar ❷ with bottom end of the needle

bar lower bushing ❸.

4) After making the adjustments mentioned in the

above steps, align the blade point E of hook ❺

with the center of needle ❹. Provide a clearance

of dimension F (reference value) between the

needle ❹ and the hook ❺, then securely tighten

three setscrews of the hook.

22. Needle-to-hook relationship

23. Height of the feed dog

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

WARNING :

Be sure to turn the power OFF before the following work in order to prevent personal injury due to

unintentional starting of the sewing machine.

❶

❷

Dimension F (mm)

DDL-900B 0.04 to 0.10

❶

❹

E

❺

F

C

D

A

B

❷

❸

A

B

0.75 to 0.85 mm (S type)

1.15 to 1.25 mm (H type)

Loading...

Loading...