41

6 Parameterization

6 Paramet erizatio n

The designation "Parameter level" is used in the setup program.

The default settings are shown in bold in the tables.

6.1 Parameter blocks

The following table shows the parameters in a parameter block. The same parameters are also available

for the second parameter block.

Depending on the controller type configured, certain parameters may be omitted or ineffective.

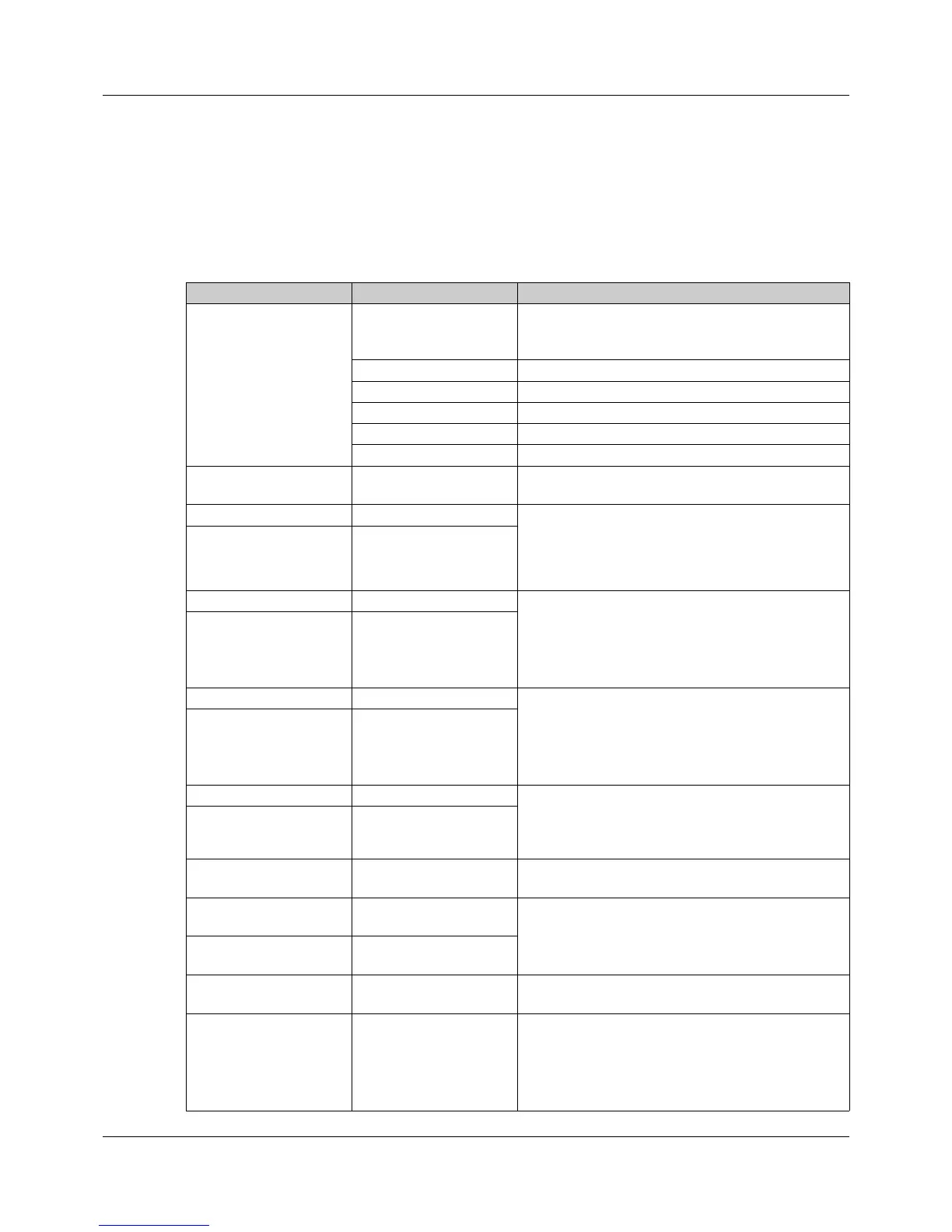

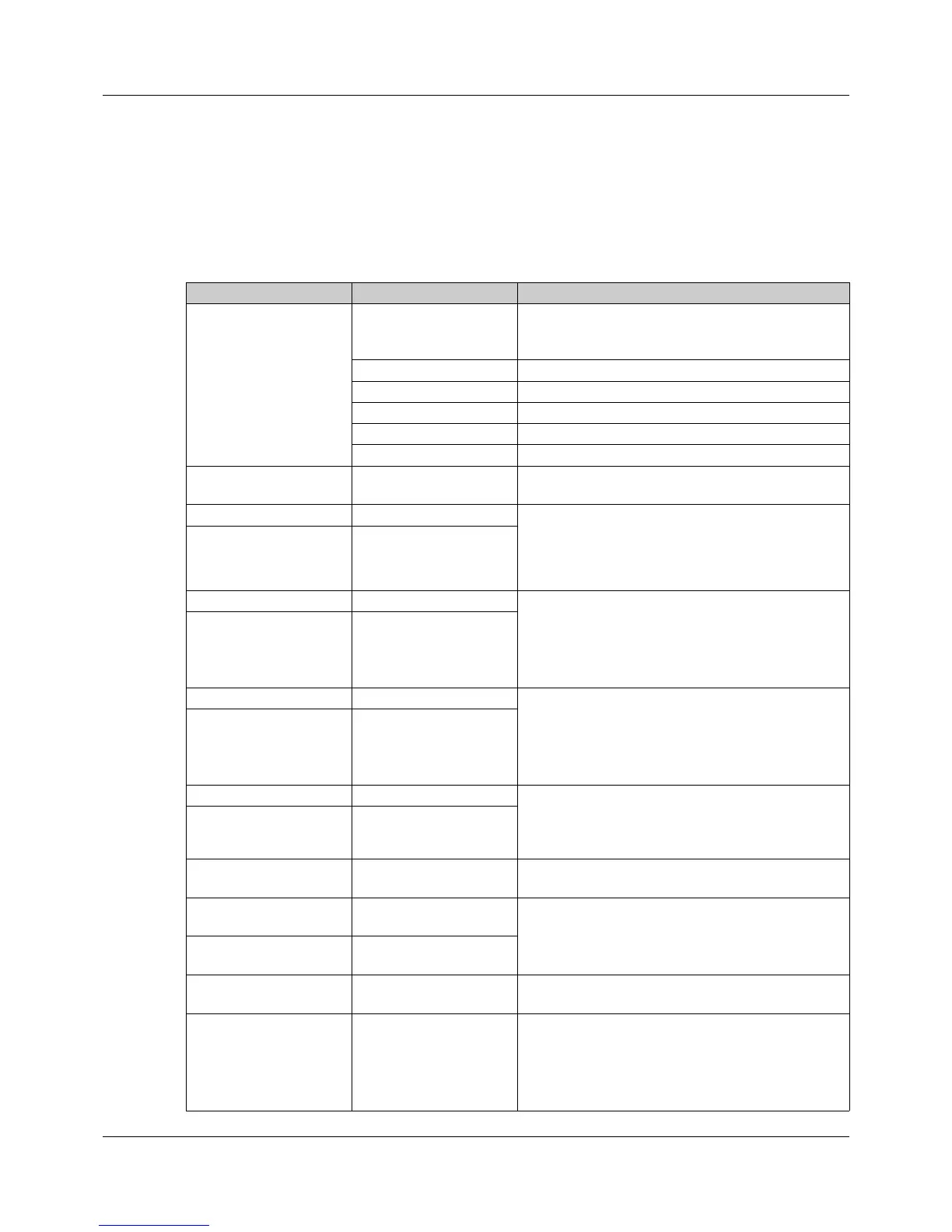

Parameter Selection/text/value Description

Control structure 1 These settings determine the control structure

(transmission behavior) and relate to the first con-

troller output.

P P controller

I I controller

PI PI controller

PD PD controller

PID PID controller

Control structure 2 (see: Control structure

1)

These settings apply to the second controller out-

put for a three-state controller.

Xp1 proportional band 0 to 9999 Value for the proportional band

The controller structure has no effect if Xp = 0 (be-

havior identical to limit value monitoring)!

For a continuous controller, Xp must be > 0.

Xp2 proportional band 0 to 9999

Tv1 derivative time 0 to 9999 (80) The derivative time (in seconds) influences the dif-

ferential component (D component) of the control-

ler output signal.

The effect of the D-term increases as the deriva-

tion time increases.

Tv2 derivative time 0 to 9999 (80)

Tn1 reset time 0 to 9999 (350) The reset time (in seconds) influences the integral

component (I component) of the controller output

signal.

The greater the reset time, the less effect the I

component has.

Tn2 reset time 0 to 9999 (350)

Cy1 cycle time 0 to 9999 (20) The cycle time (in seconds) should be chosen so

that the energy supply to the process is as contin-

uous as possible without overloading the switching

elements.

Cy2 cycle time 0 to 9999 (20)

Xsh contact spacing 0 to 999 Spacing between the two control contacts of a

three-state controller and three-step controller

Xd1 switching differen-

tial

0 to 999 (1) Hysteresis for a switching controller with propor-

tional band Xp = 0

Xd2 switching differen-

tial

0 to 999 (1)

TT actuator time 5 to 3000 (60) Control valve running time range (in seconds)

used for a three-step controller

Y0 working point -100 to +100 (0) Working point correction (in percent) for a P or PD

controller (correction value for the output level)

If the actual value has reached the setpoint value,

the output level corresponds to the working point

Y0.

Loading...

Loading...