10 Cooling System

10.1 Installation of liquid-cooled devices

In continuous operation liquid-cooled drive converters are operated with lower tempera-

turethanair-cooledinverters.Thishaspositiveeectsonlifetime-relevantcomponents

such as fan and DC link capacitors and power modules (IGBT). Also the temperature de-

pendentswitchinglossesarepositivelyeected.Theuseofliquid-cooledCOMBIVERT

driveconvertersisoeredinthedrivetechnology,becausethereareprocess-caused

coolants available with some applications.

10.1.1 Heat sink and operating pressure

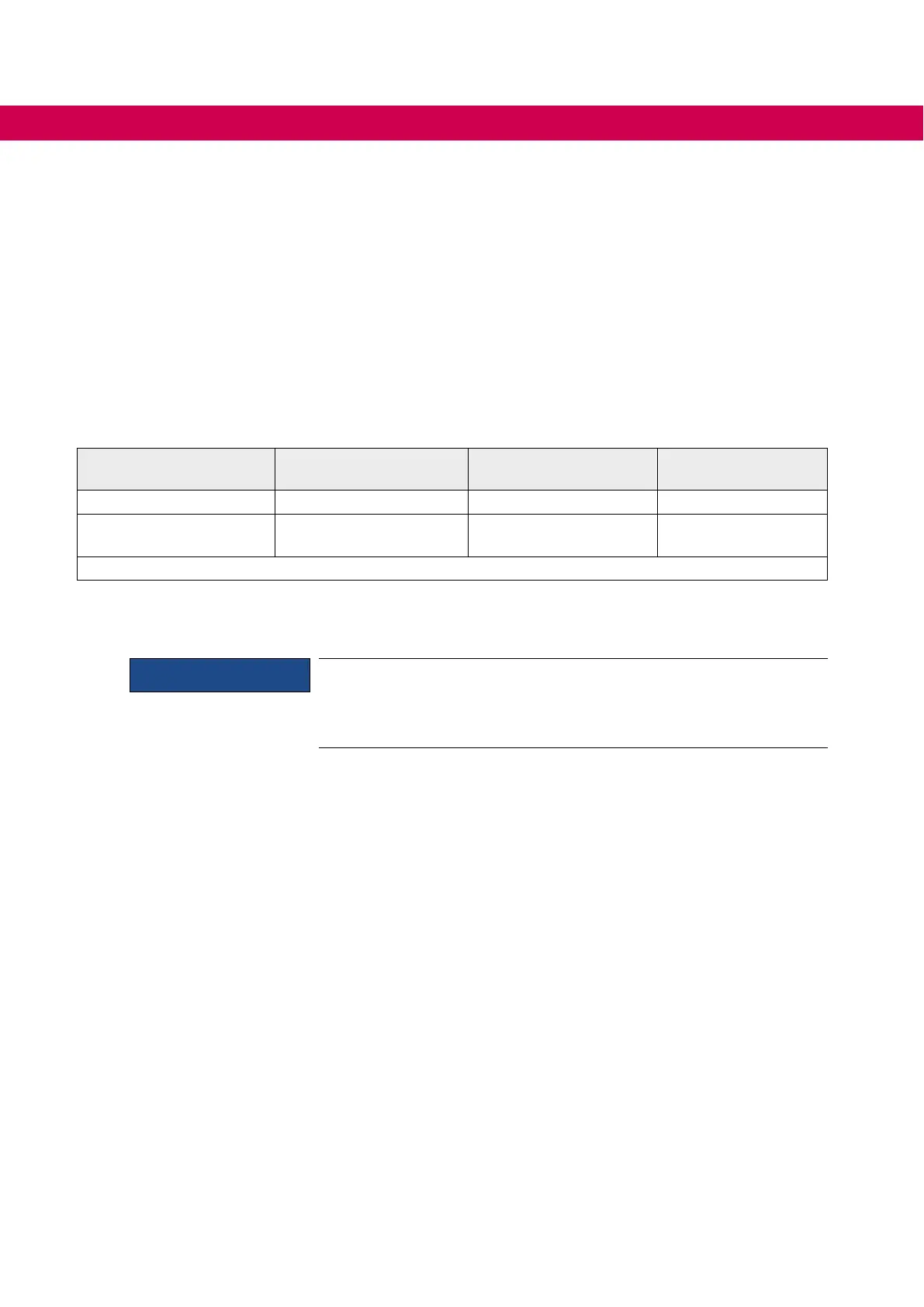

Design system Material (voltages)

Max. operating

pressure

Connecting duct

Extrusion casting heat sink Aluminium (-1.67 V) 10 bar 0000650-G140

Cooling plate with

pressed pipes

Stainless steel (-1.04V) 6 bar upon request

Table 21: Heat sink and operating pressure

The aluminium liquid coolers are sealed by sealing rings and posses a surface protec-

tion (anodized) even in the ducts.

NOTICE

In order to avoid a deformation of the heat sink and the damages there-

by,theindicatedmax.operatingpressuremaynotbeexceededbriey

also by pressure peaks.

Pay attention to the Directive 2014/68/EU of pressure equipment.

10.1.2 Materials in the cooling cicuit

For the screw connections and also for the metallic articles in the cooling circuit which

are in contact with the coolant (electrolyte) a material is to be selected, which forms a

smallvoltagedierencetotheheatsinkinordertoavoidcontactcorrosionand/orpitting

corrosion (electrochemical series, see table). An aluminum screw connection or ZnNi

coated steel screw connection is recommended. Other materials must be examined in

eachcasebeforeemployment.Thespeciccaseofapplicationmustbecheckedbythe

customerintuningofthecompletecoolingcircuitandmustbeclassiedaccordingtothe

used materials. With hoses and seals take care that halogen-free materials are used.

A liability for occuring damages by wrongly used materials and from this resulting corro-

sion cannot be taken over!

62

COOLING SYSTEM

Loading...

Loading...