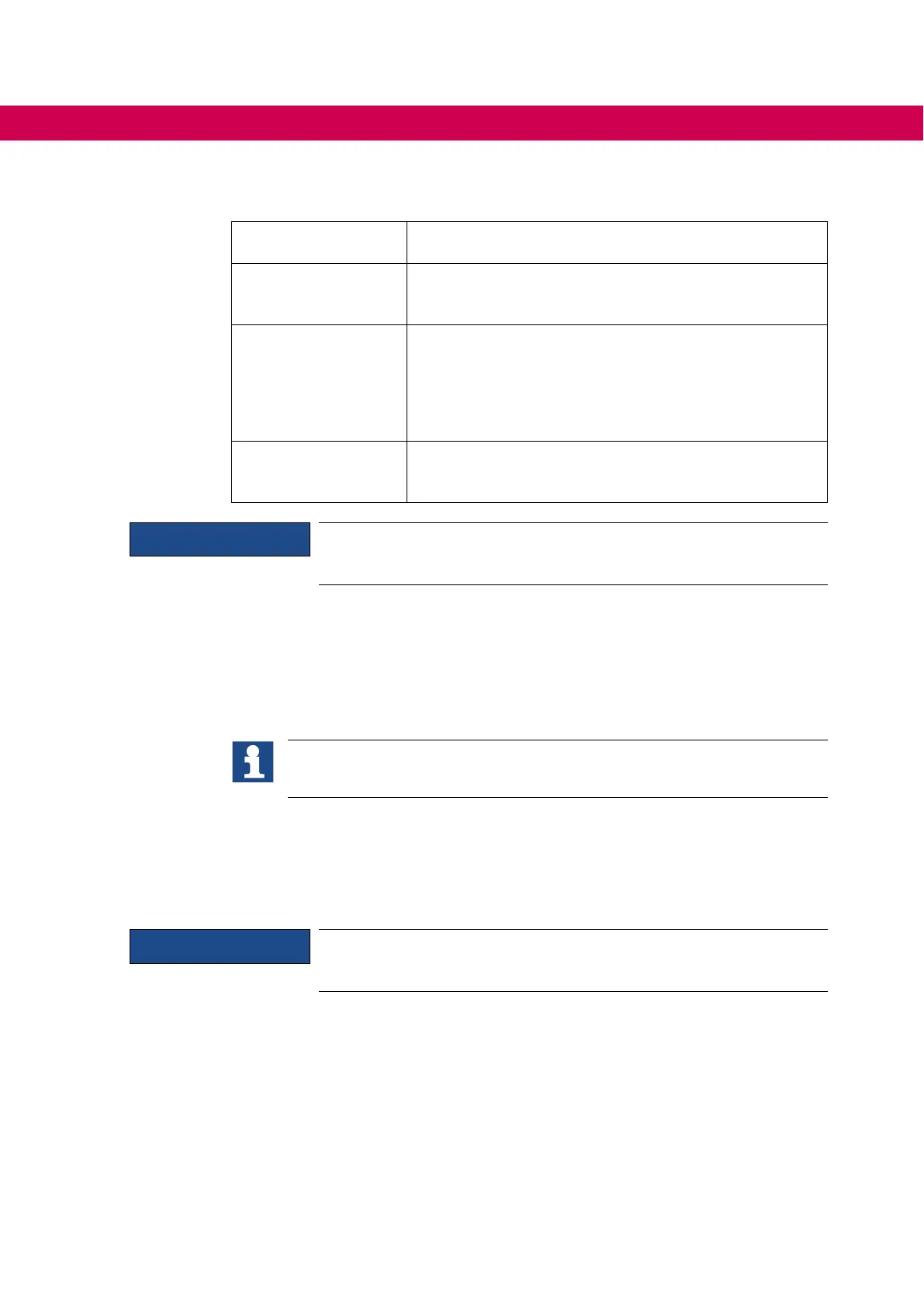

Special requirements for open and half-open cooling systems:

Impurities Mechanical impurities in half-open cooling systems can be

counteractedwhenappropriatewaterltersareused.

Salt concentration The salt content can increase through evaporation at half-

open systems. Thus the water is more corrosive. Adding of

fresh water and removing of process water works against.

Algae and myxobacte-

ria

Algae and myxobacteria can arise caused by increased wa-

ter temperature and contact with atmospheric oxygen. The

algaeandmyxobacteriaclogtheltersandobstructthewa-

ter-ow.Biocidecontainingadditivescanavoidthis.Espe-

cially at longer OFF periods of the cooling circuit preventive

maintenance is necessary.

Organic materials The contamination with organic materials must be kept as

small as possible, because separate slime can be caused

by this.

NOTICE

Damages at the unit which are caused by clogged, corroded heat sinks

or other obvious operating errors, leads to the loss of the warranty claims.

10.1.4 Coolant temperature

Theowtemperaturemaynotexceed40°C.Themaximumoverheattemperatureis

60°C or 90°C depending on the power unit and overload capacity. The coolant temper-

atureisspeciedinthetechnicaldata.

Theowtemperatureshouldbechosendependingonthevolumeow,so

that at rated operation the heatsink temperature is always 10K below the

overheat temperature level. As a result, a sporadic shutdown is avoided.

10.1.4.1 Moisture condensation

Due to high air humidity and high temperatures it can lead to moisture condensation.

Moisture condensation is dangerous for the drive converter, because the drive converter

can be destroyed through eventual occuring short circuits.

NOTICE

The user must guarantee that any moisture condensation is avoided!

10.1.4.2 Supply of temper coolant

This is possible by using heatings in the cooling circuit for the control of the coolant tem-

perature. The following dew point table is available for this:

64

COOLING SYSTEM

Loading...

Loading...