GB - 42

Annex

Annex C

C.1 Installation of water-cooled units

In continuous operation water-cooled inverters are operated with lower temperature than

air-cooled inverters. This has positive effects on lifetime-relevant components such as fan

and DC link circuit capacitors and power modules (IGBT). Also the temperature dependent

switching losses are positively effected. The use of water-cooled KEB COMBIVERT frequen-

cy inverters is offered in the drive technology, because there are process-caused coolants

available with some applications. The following instructions must be observed absolutely

when this units are used.

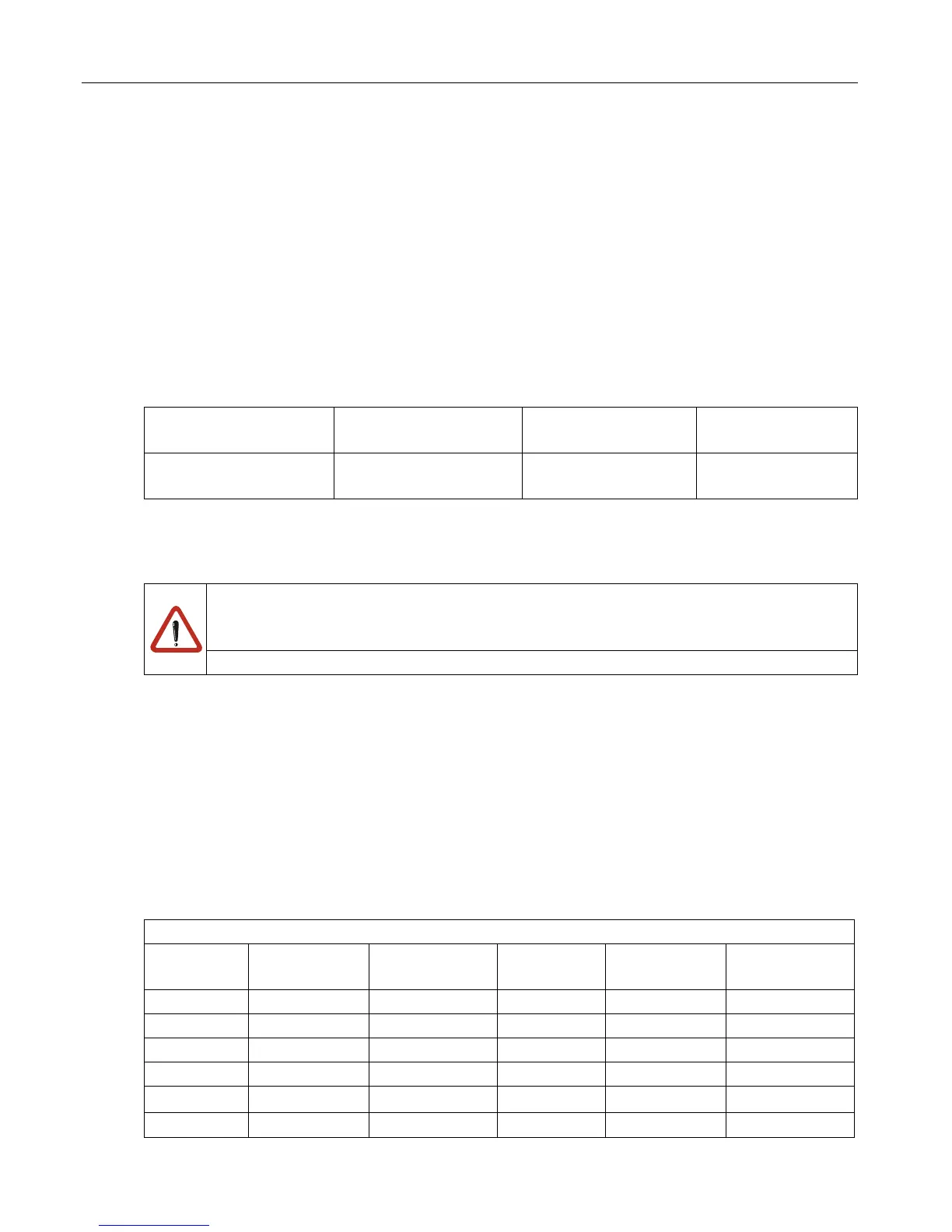

C.1.1 Heat sink and operating pressure

Design system Material (voltages) Max. operating pres-

sure

Connecting duct

Extrusion casting heat

sink

Aluminium (-1.67 V) 10 bar 0000650-G140

The heat sinks are sealed with sealing rings and posses a surface protection (anodized) even

in the ducts.

In order to avoid a deformation of the heat sink and the damages involved, the

indicatedmax.operatingpressuremaynotbeexceededbrieyalsobypressure

peaks.

Pay attention to the guidelines 97/23/EG of pressure units.

C.1.2 Materials in the cooling cicuit

For the screw connections and also for the metallic articles in the cooling circuit which are in

contact with the coolant (electrolyte) a material is to be selected, which forms a small voltage

difference to the heat sink in order to avoid contact corrosion and/or pitting corrosion (elec-

tro-chemical voltage series, see table 1.5.2). An aluminum screw connection or ZnNi coated

steel screw connection is recommended. Other materials must be examined in each case

beforeemployment.Thespeciccaseofapplicationmustbecheckedbythecustomerin

tuningofthecompletecoolingcircuitandmustbeclassiedaccordingtotheusedmaterials.

With hoses and seals take care that halogen-free materials are used.

A liability for occuring damages by wrongly used materials and from this resulting corrosion

cannot be taken over!

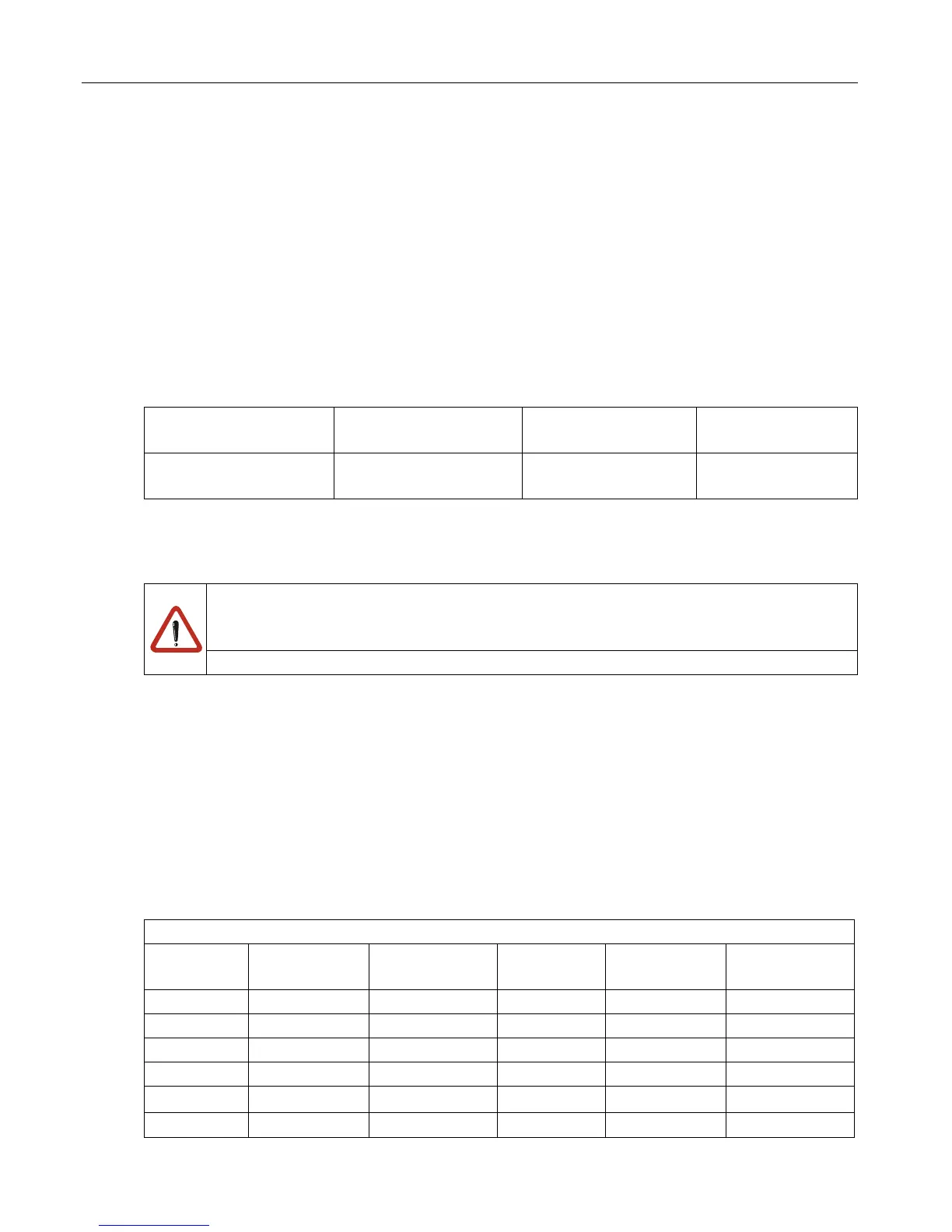

Table 1.5.2 Electro-chemical voltage series / standard potentials against hydrogen

Material generated Ion Standard po-

tential

Material generated Ion Standard po-

tential

Lithium Li

+

-3.04 V Cobald Co

2+

-0.28 V

Potassium K

+

-2.93 V Nickel Ni

2+

-0.25 V

Calcium Ca

2+

-2.87 V Tin Sn

2+

-0.14 V

Sodium Na

+

-2.71 V Lead Pb

3+

-0.13 V

Magnesium Mg

2+

-2.38 V

Iron Fe

3+

-0.037 V

Titan Ti

2+

-1.75 V Hydrogen 2H

+

0.00 V

Loading...

Loading...