EN

NOTE! In all cases the chassis design is not recommended for lifting its weight clear of the

ground by the handles or any other means, with or without a gas cylinder loaded in place. When

transporting the machine between sites, welding gas cylinders must be removed from the chassis,

secured and transported by other means.

4. BEFORE YOU START USING THE UNIT

4.1 Installing ller wire

Kempact RA is designed for 300 mm wire spools and the following ller wire types:

• solid wires

• ux-cored wires

• self-shielded ux-cored wires

• stainless steel wires

• aluminium wires

• brazing wires

When choosing appropriate ller materials, remember that the wire must have approximately

the same melting point as the base material to be welded. MIG brazing process is an exception

to this rule.

NOTE! When changing the ller wire, always check that the feed rolls, their groove shape and size

and the wire liner inside the welding gun cable are suitable for the wire you are using. Also check

that you are using the correct polarity for the ller wire.

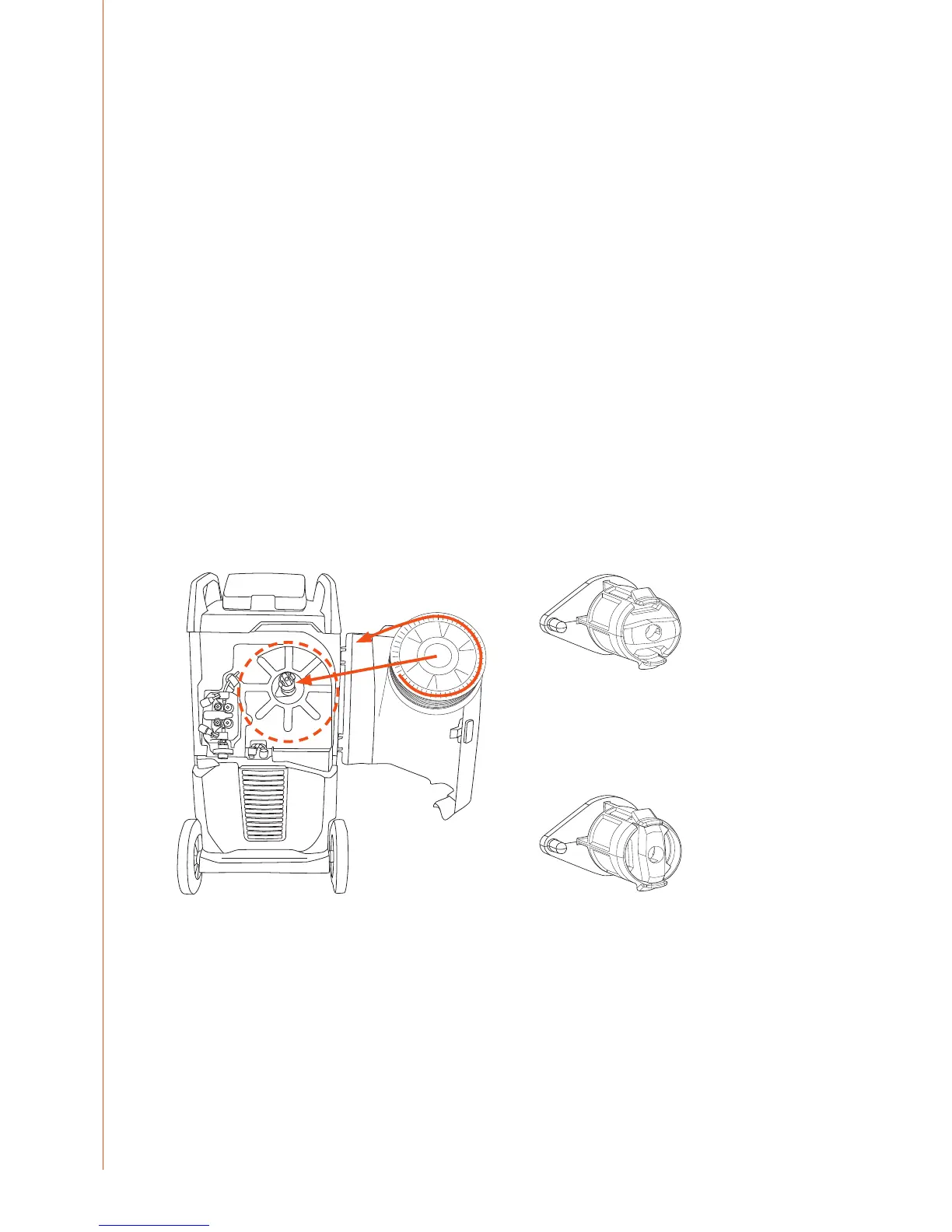

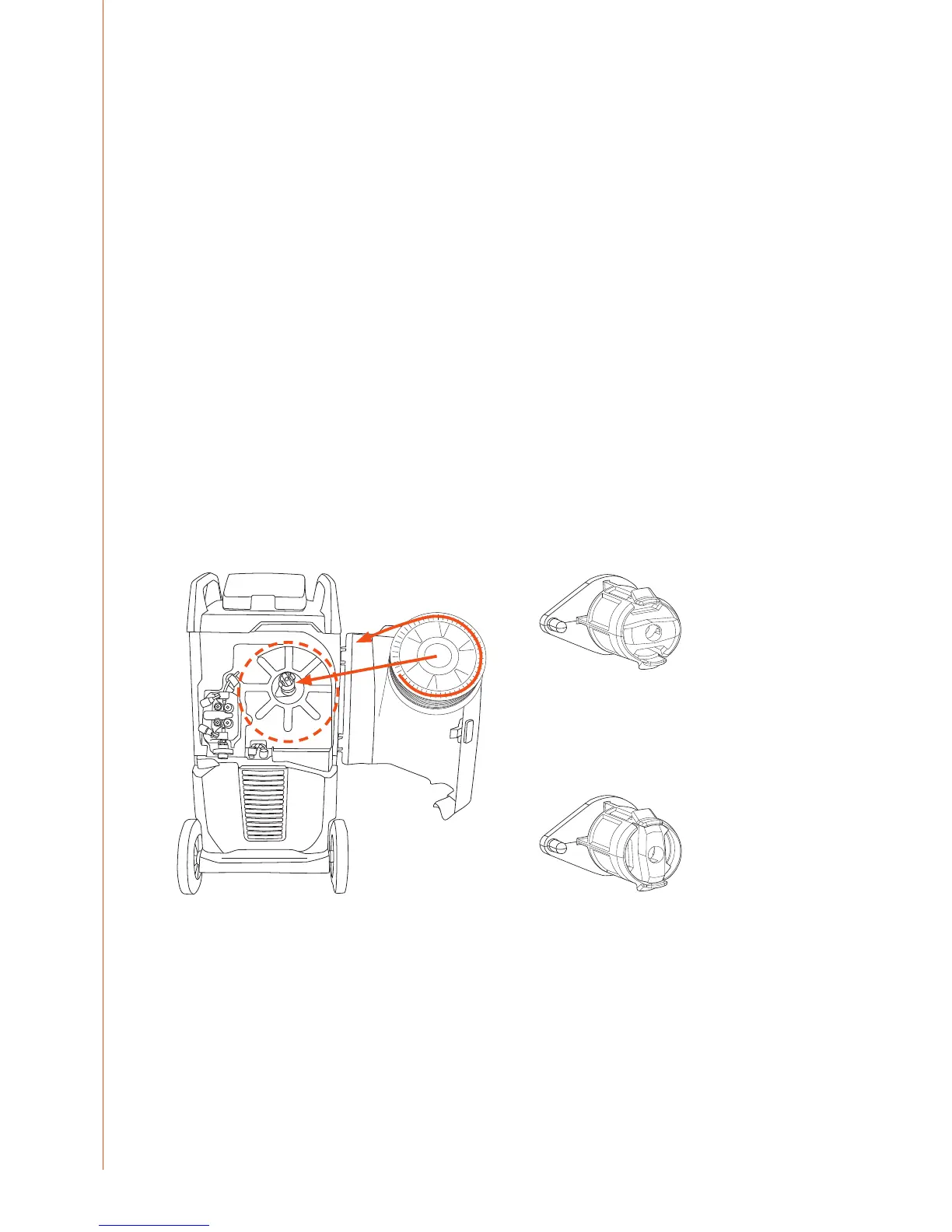

4.2 Mounting and locking of ller wire spool

2.

1.

3.

To mount the wire spool:

1. Turn the locking knob of the spool holder so that the locking clips are opened (1).

2. Check the rotating direction of the wire spool and push the spool into its place so that it

rotates in the right direction (2).

3. Turn the locking knob of the spool holder to close the locking clips (3).

NOTE! Check that the ller wire spool is correctly mounted and locked into position. Ensure the

spool is not damaged or deformed in such a way that it can rub or cha against the internal

surface of the wire feed unit chassis or door. This may result in increased drag, impacting on weld

quality. This may also result in long term wire feed unit damage, rendering the unit unserviceable

or unsafe to use.

Kempact 251R, 253R, 323R, 181A, 251A, 253A, 323A

10

Loading...

Loading...