3.

潤滑油及冷卻油

選用潤滑油及冷卻油

LUBRICATION OIL AND COOLING OIL

潤滑油在機器的使用壽命上佔很重要的地位,而冷卻油對縫製的效果有很大的影響。千萬不可疏忽潤

滑油,請使用 或同等級的產品,冷卻油請使用矽油 。

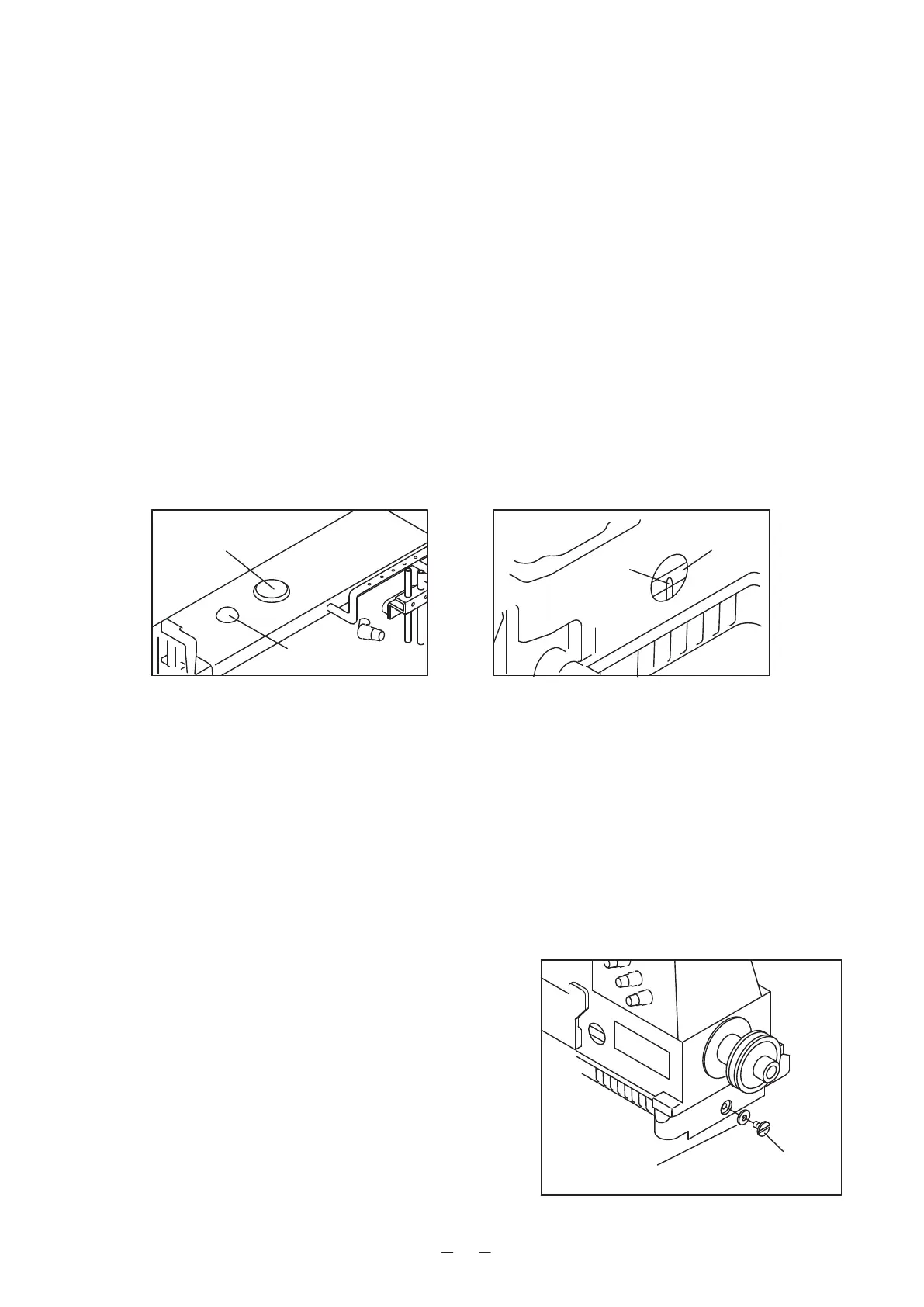

本機器在出廠時已把潤滑油全部排除,在新機器使用前或長期使用後油量不足時,請打隍`油孔塞

加入新潤滑油,添加潤滑油的同時注意油面計浮標上的紅點切不可超過上限,隆l運轉時請注意循

環視窗必須確認潤滑油是否噴。

浮標

油面計

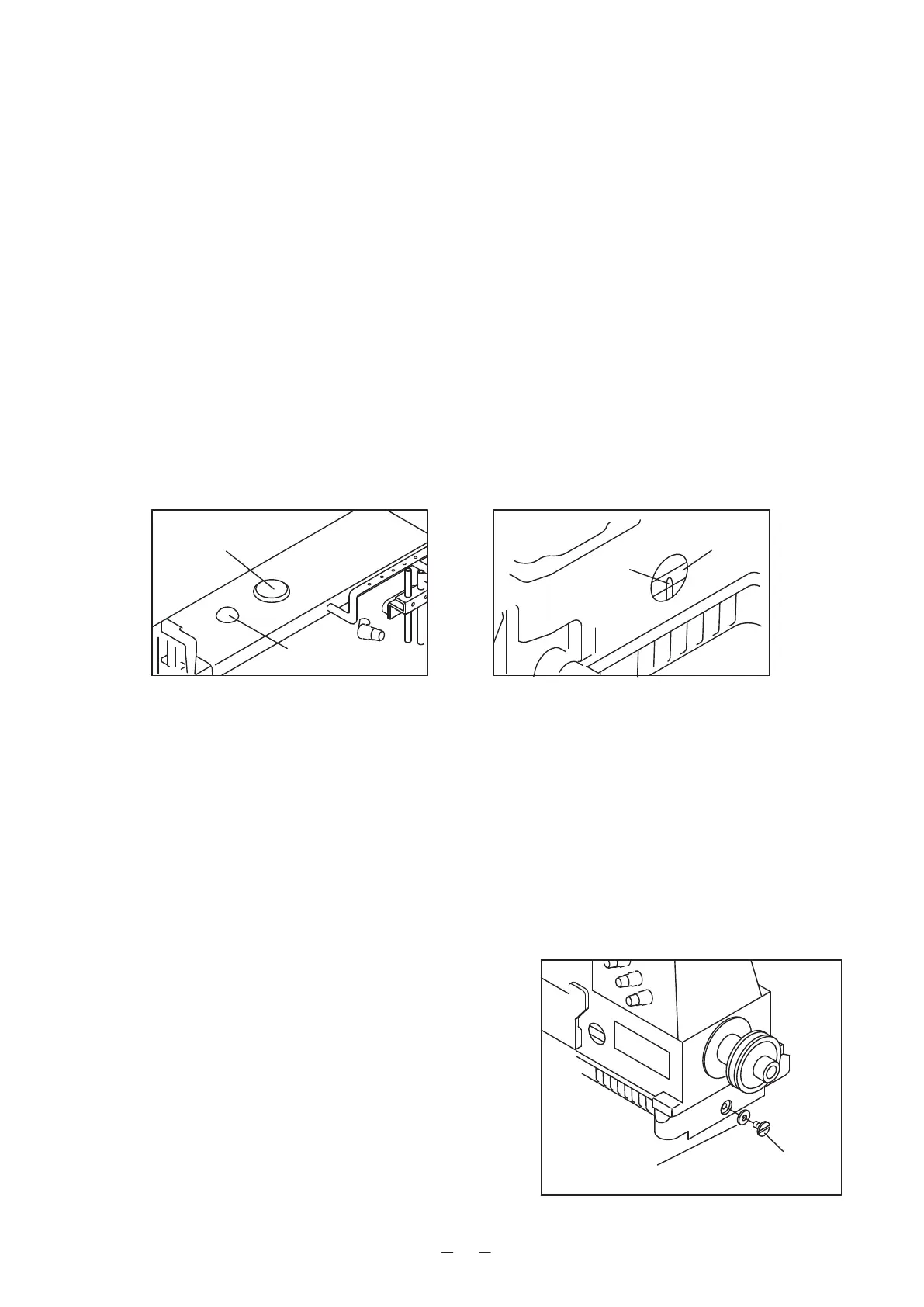

新機器在 個使用小時或是長時間使用後潤滑油必須更新,排放舊油時打開皮帶護蓋取下 形皮帶

,將縫機移出承座放鬆排油螺絲,放掉舊油注意廢油不可污染到 形皮帶,完成後依反向順序裝回零

件,確實鎖緊排油螺絲。添加新油時參照上節說明。

MOBIL#10

(SILICON OIL)

PLEASE USE MOBIL #10 OR EQUIVALENT OIL FOR LUBRICATION OIL AND USE SILICONE OIL FOR

COOLING OIL.

THE LUBRICATION OIL HAS BEEN DRAINED OFF COMPLETELY BEFORE DELIVERY, ADDING OIL TO THE

UPPER LINE OF OIL GAUGE (C) BY REMOVING SEAL PLUG (A).ALSO,PLEASE MAKE SURE THE OIL

FLOWS OUT OF NOZZLE (B) AT THE START OF OPERATION.

250

V

FOR THE LONGER LIFE OF MACHINE,CHANGE LUBRICATION

INITIAL OPERATION.

A. AFTER TAKING OFF BELT COVER,REMOVE V-BELT

油封 排油螺絲

4

CHANGING OIL

LUUBRICATION OIL AND COOLING OIL

3-1

3-2

添加潤滑油

FEEDING OIL

換油

3-3

V

D. WHEN REPLENISHING OIL PLEASE REFER TO

C. AFTAER DRAINING, TIGHTEN SCREW (D) BACK.

B. LOOSEN SCREW (D) AND DRAIN OFF ALL THE OIL

FROM MACHINE TABLE.

棒上先潤滑針棒。

當新機器剛開始使用時,或機器已有一段時間未曾使用而再度要使用時,煩在使用前滴幾滴機油在針

BEFORE STARTING A BRAND NEW MACHINE OR A MACHINE WHICH HAS NOT BEEN USED FOR MORE THAN

A COUPLE OF WEEKS,LUBRICATE THE NEEDLE BAR FIRST.

FROM MOTOR PULLEY, AND REMOVE MACHINE HEAD

PARAGRAPH 3-2 " FEEDING OIL" ABOVE.

OIL GAUGE

POINTER

FROM THE MACHINE.

SCREW

(C)

OIL COMPLETELY AFTER 250 HOURS (OR 4 WEEKS) OF

(D)

OIL SEAL

(B)

OIL WINDOW

OIL HOLE

K

i

n

gte

x

循環視窗

注油孔塞

Loading...

Loading...