Pressure Independent VAV Applications with CEP/CSP-4000 Series 53 CTE-5202 Applications Guide, AN0912A Rev. D

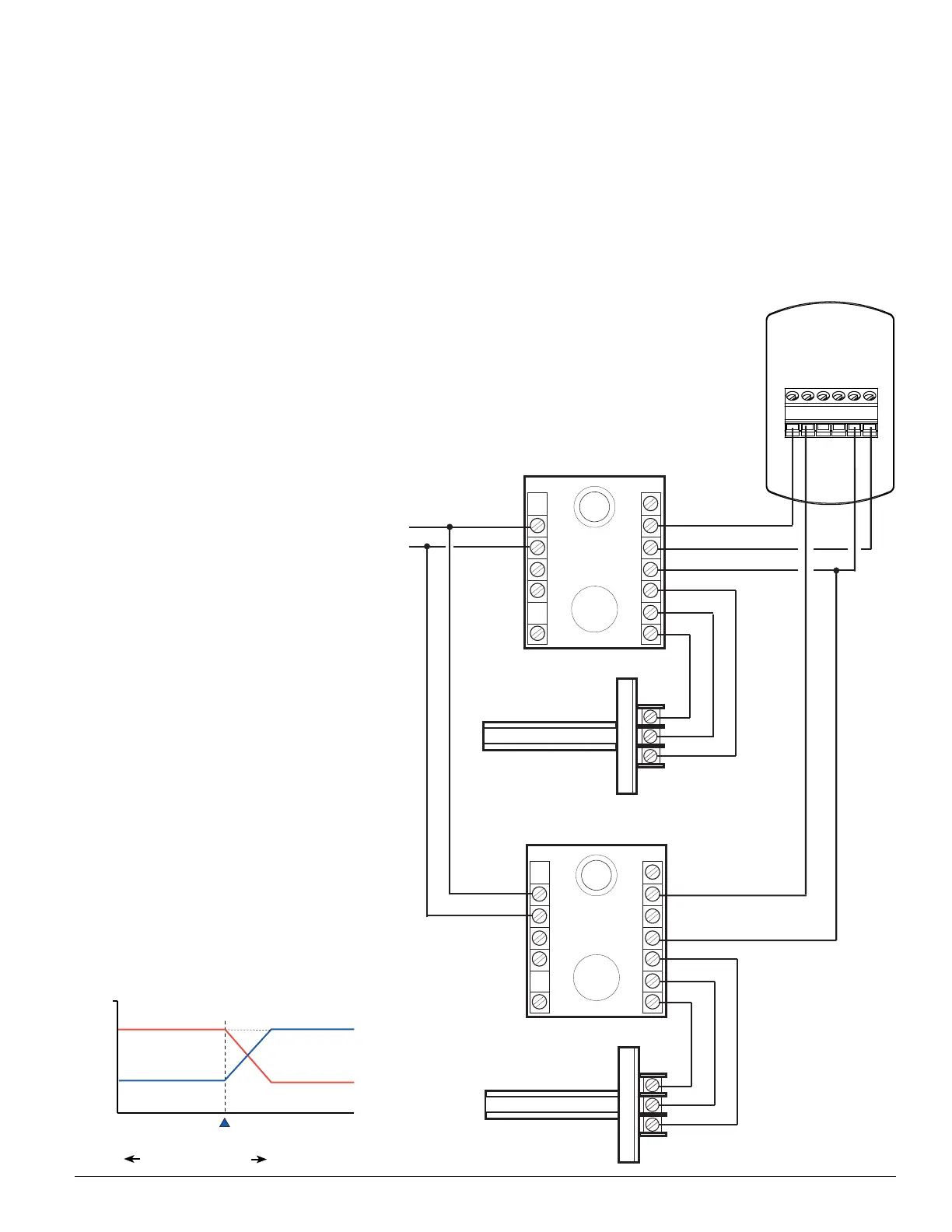

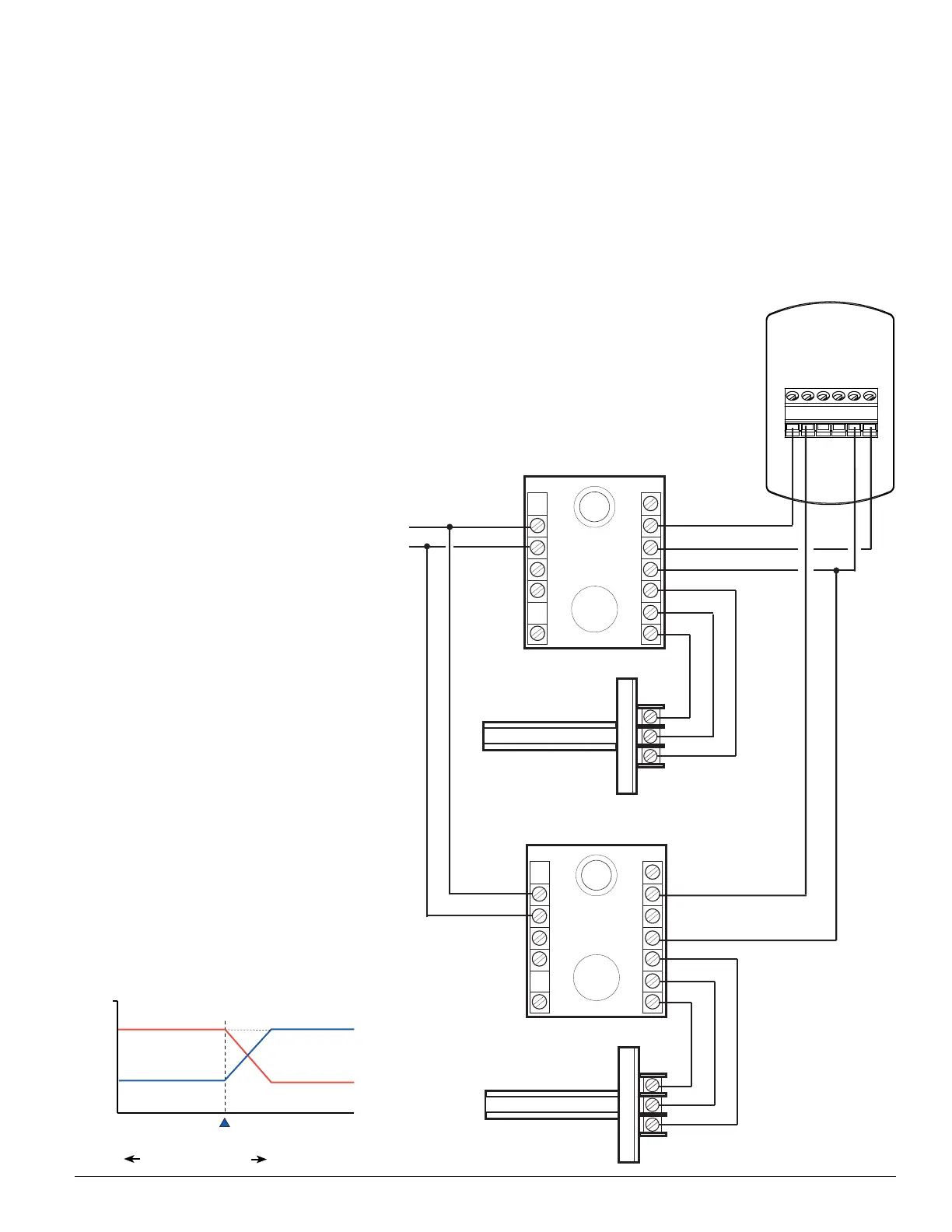

Dual Duct Heat/Cool Constant Volume with Hot Deck Make-Up

NOTE: Minimum and

maximum to be set

on the cooling side

(AO1) in the CTE-

5202 LIMITS menu.

(Heating side makes up

the remainder for the

constant volume.)

Constant volume seing

must be equal to or

greater than cooling

maximum.

Set constant volume

on the heating side by

adjusting maximum

for AO2 to 10 VDC

and adjusting AO2

minimum (volts) for

the desired constant

volume. (See the

Voltage/Velocity

Correlation chart in

the CEP-4000 Series

Applications Guide.)

This application is designed for dual-duct

installations requiring constant air volume (CAV).

In this application, a single-duct cooling controller

is mounted on the cold air duct, and its minimum

and maximum ow is reset by the room thermostat.

A second “slave” controller is mounted on the hot

air duct as a constant volume unit, with the ow

sensor measuring downstream “total ow” into the

space. (The “slave” controller has no reset from the

thermostat.)

As the cold deck resets from maximum to minimum

ow, the hot deck controller senses a decrease in

“total ow” to the space, opens the hot air duct

to compensate, and thus maintains a constant

combined airow into the room.

~

T

T

AI1

AO1

AO2

CTE-5202

Thermostat

24 VAC @ 20 VA

~

–

(Phase)

(Neutral)

1

2

3

7

6

5

4

3

2

1

8

9

10

11

12

13

14

CEP-4xxx

Controller-Actuator

(Hot Deck) SSE-1001/1002

Flow Sensor (Located

in Common Discharge)

1

2

3

7

6

5

4

3

2

1

8

9

10

11

12

13

14

CEP-4xxx

Controller-Actuator

(Cold Deck) SSE-1001/1002

Flow Sensor (Located

in Cold Air Inlet)

Sequence 3 should be selected from the CTE-5202

SYSTEM menu. See Change Conguration on page 6.

(See also the Dual Heating/Cooling Constant Volume

w/ Hot Deck Make-Up section with a CTE-1103 in

the CEP-4000 Series Applications Guide.)

Select Sequence 3

Loading...

Loading...