6

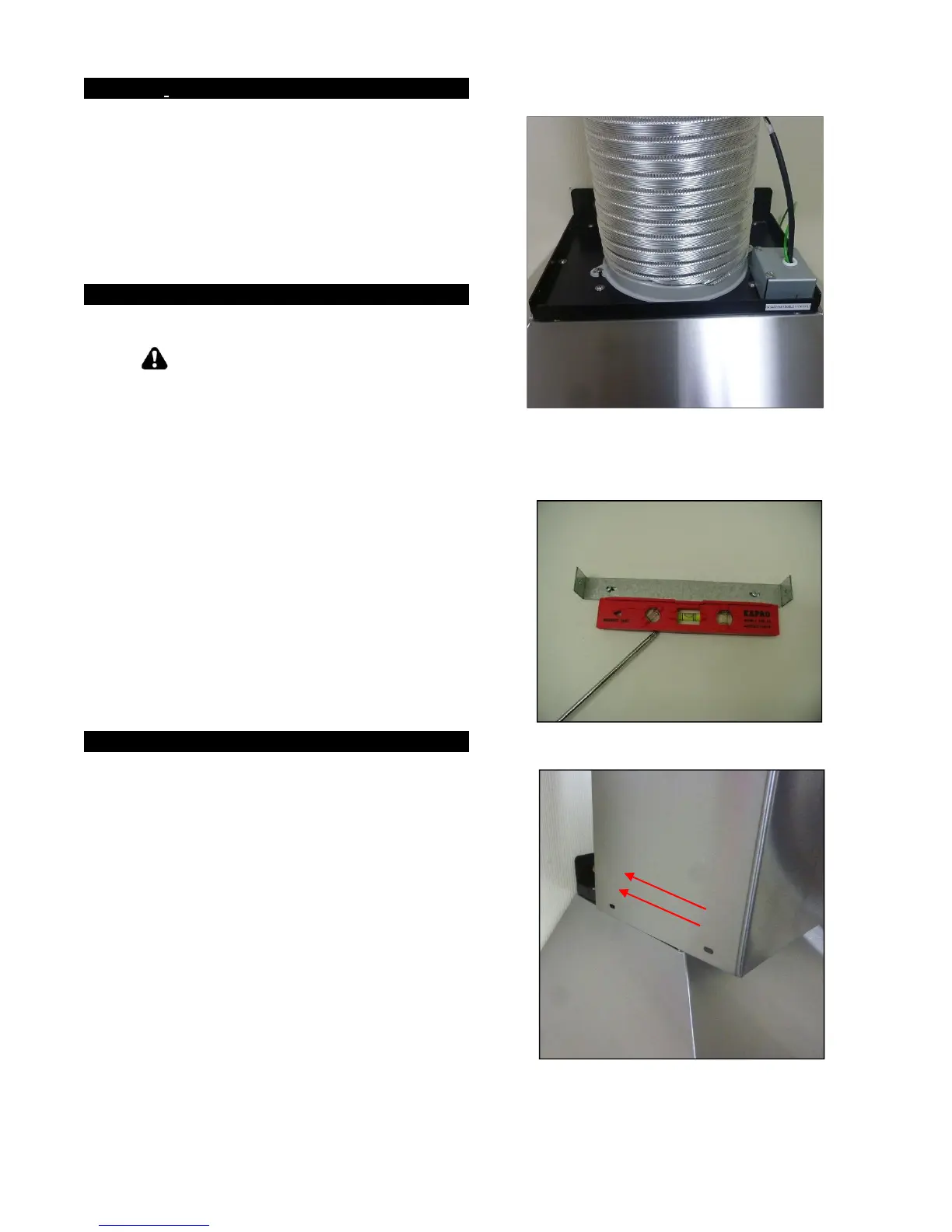

Ductwork Installation

5. Use 6” round steel pipe (not provided) to

connect the plastic exhaust on the hood to the

ductwork above. Use duct tape to make all

joints secure and air tight.

Refer to Figure 4.

THIS RANGE HOOD MUST BE

PROPERLY GROUNDED. MAKE SURE

THIS IS DONE BY QUALIFIED

ELECTRICIAN IN ACCORDANCE WITH

ALL APPLICABLE NATIONAL AND LOCAL

ELECTRICAL CODES. BEFORE

CONNECTING WIRES, SWITCH POWER

OFF AT SERVICE PANEL AND LOCK

SERVICE PANEL TO PREVENT POWER

FROM BEING SWITCHED ON

ACCIDENTALLY.

- If hood is operating normally, connect three

wires (black, white and green) to house wires

and cap with wire connectors.

- Store wires in the wiring box.

Duct Cover Installation

NOTE: BE CAREFUL WHEN USING

ELECTRICAL SCREWDRIVER, DAMAGE TO

THE HOOD MAY OCCUR.

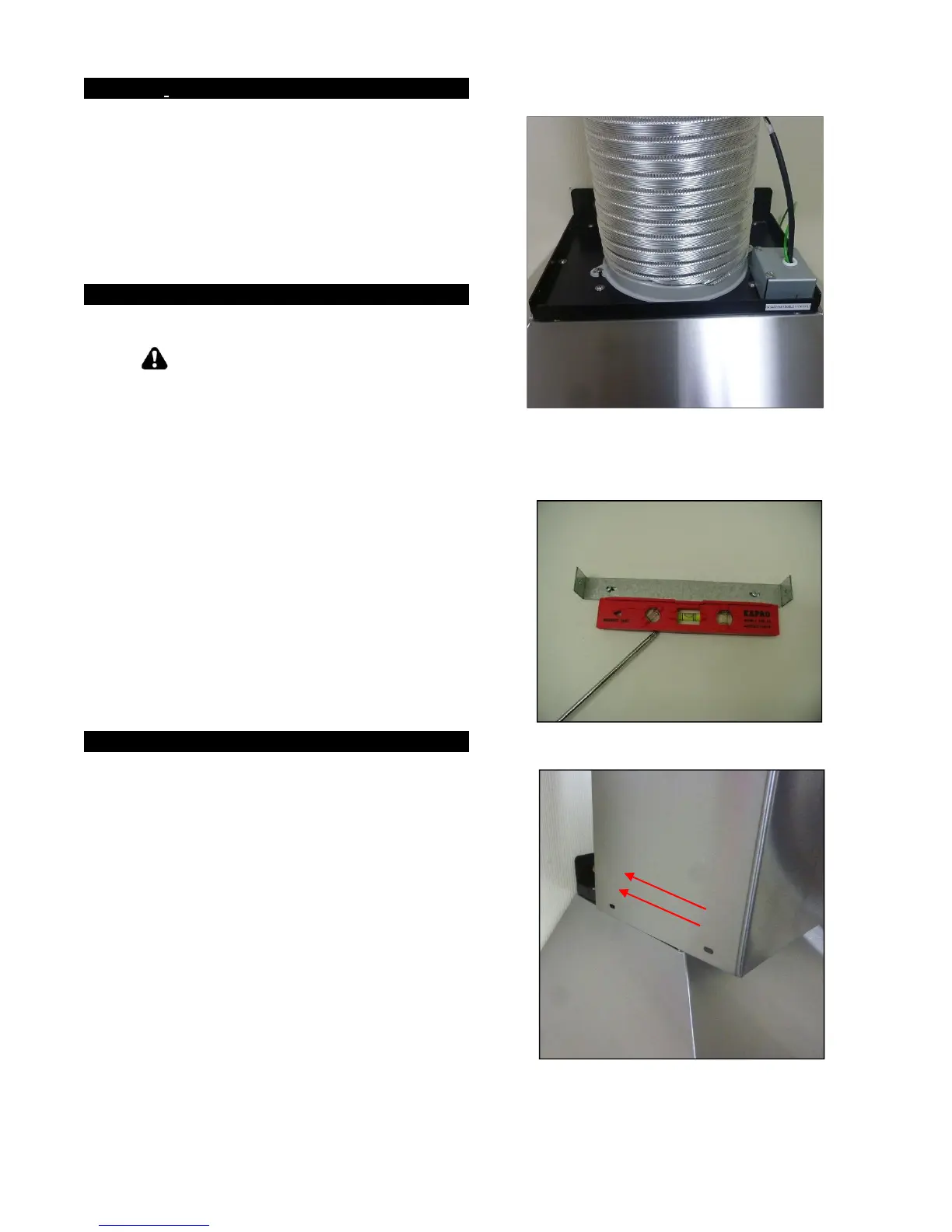

6. Using reference E from Table 1 and

measurements on pages 11-12, mark the

leveling point for duct cover bracket.

7. Secure the duct cover mounting bracket to the

wall with two screws (not provided). Make

sure all screws are tightened Refer to Figure

5. NOTE: Inner duct cover will cover the duct

cover bracket.

8. Slide the entire duct cover onto the hood.

Refer to Figure 6.

Figure 4

Figure 5

Figure 6

Wiring to Power Supply

Loading...

Loading...