TP-6161 1/12 15Section 1 Specifications and Features

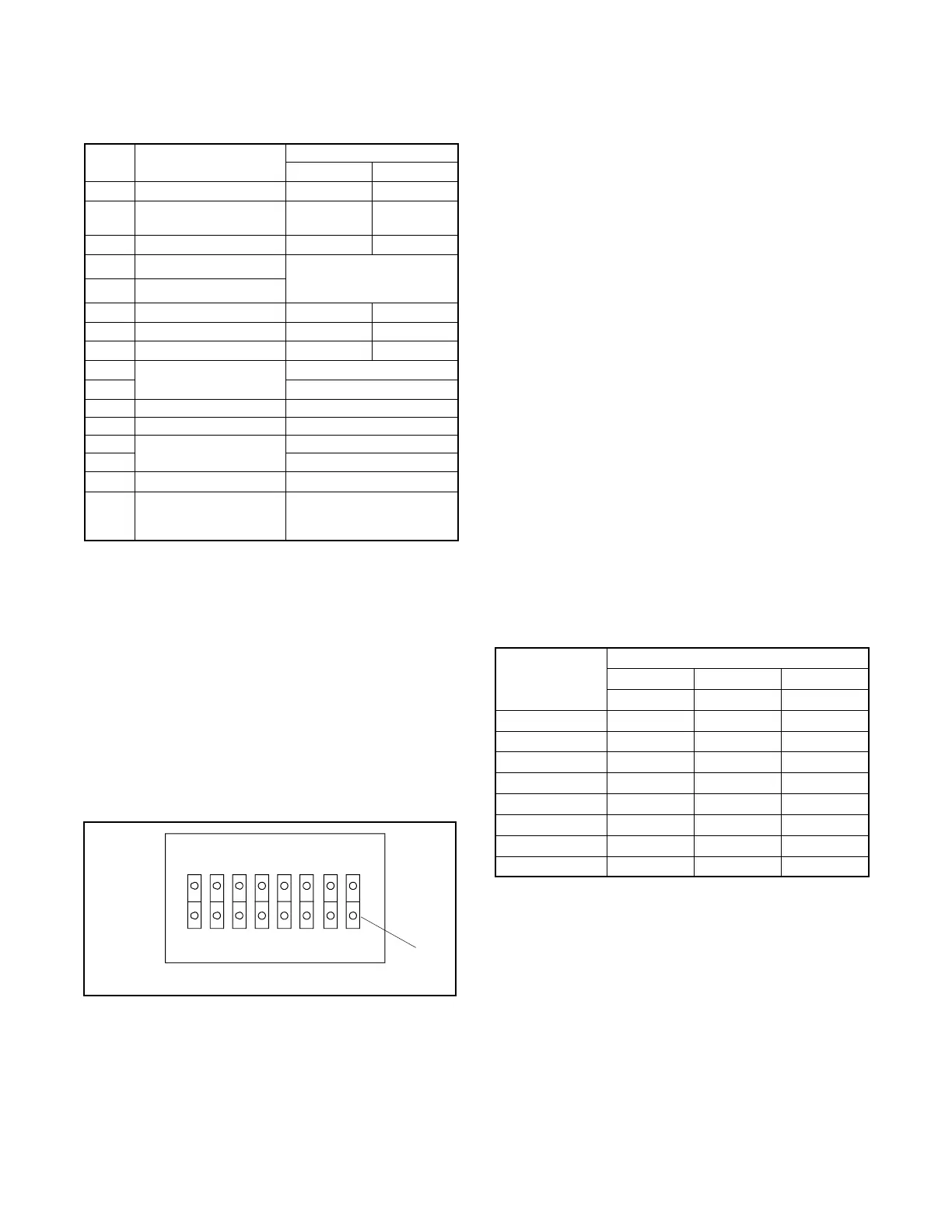

1.2.7 DIP Switches

The controller circuit board contains eight DIP switches,

seeFigure1-9.

DIP

Switch

Descri

tion

Switch Position

Open Closed

1 Overspeed selection 60 Hz 70 Hz

2 Temperature Cooldown

Enable

Cooldown

Disabled

Cooldown

Functional

3 Crank Mode Selection Cyclic Continuous

4 Engine Comm. Setting

See selections for

DIP switch 4 and

DIP switch 5 below

5 Engine Comm. Setting

6

Modbusr Address Bit 0

Value=0 Value=2

7

Modbusr Address Bit 1

Value=0 Value=4

8

Modbusr Address Bit 2

Value=0 Value=8

4

No ECM

Open

5 Open

4 MDEC/ADEC Comm. Closed

5 Isochronous Open

4

J1939 Communication

Open

5 Closed

4 MDEC/ADEC Comm. Closed

5 Governor (VSG)

(Doosan, GM, and

Volvo engine only)

Closed

Figure 1-9 DIP S witch Functions

Note: After setting DIP switches to the generator set

application, be sure to power down and then

power up the controller (disconnect the battery

and then reconnect the battery of the generator

set) or use the prime power switch, if equipped.

The controller will NOT acknowledge the DIP

switch change until after generator set controller

is powered up.

Push down the end of the DIP switch near the OPEN

label to open the switch, or push down the other end to

close it. See Figure 1-10.

6126

1. Push this side down to open circuit.

OPEN

123

1

45 6 78

Figure 1-10 DIP Switch Open Position

Typically, the factory default settings have all the DIP

switches in the closed position except the crank mode

selection switch SW3 which is open for cyclic cranking.

The overspeed selection switch SW1 is open on 50 Hz.

units. Be sure to select the correct DIP switch

configuration for each generator set application.

Overspeed Frequency (DIP Switch 1). The generator

set overspeed frequency is set using DIP switch 1.

Select 70 Hz for 60 Hz voltages and 60 Hz for 50 Hz

voltages.

Temperature Cooldown (DIP Switch 2). The

generator set will continue to run during a five-minute

cooldown cycle or s hut down immediately. The choice is

made using DIP switch 2.

Engine Cranking (DIP Switch 3). The controller is

factory-set for cyclic cranking. To change to the

continuous cranking mode, use DIP switch 3.

Engine Configuration (DIP Switches 4 and 5). See

Figure 1-9 for the DIP switch positions based on engine

configurations regarding non-ECM, MDEC, and J1939

engine communication selections.

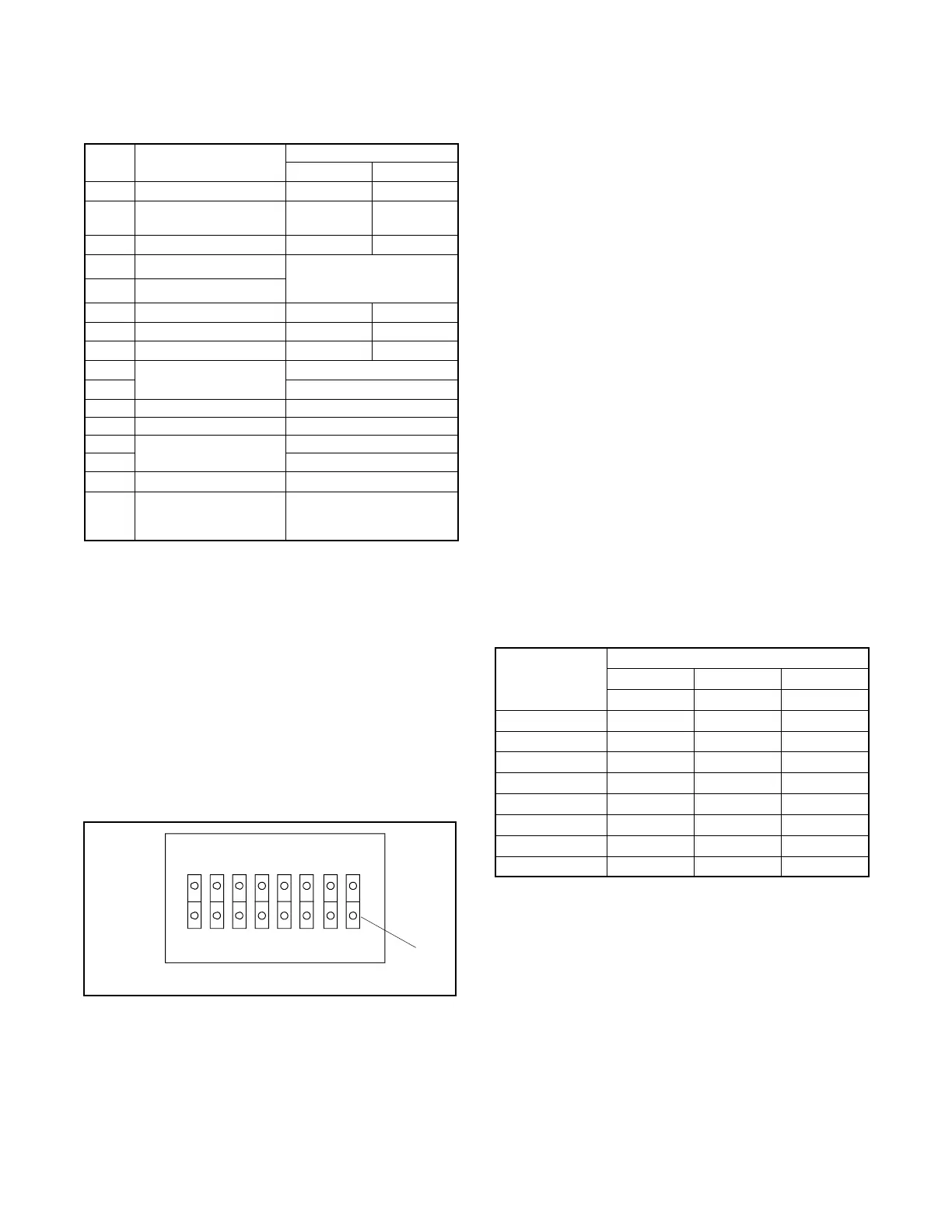

Modbusr Address (DIP Switches 6--8). Each

Modbusr device requires a unique address. Address

numbers are created using a binary number system with

DIP switches 6 --8. Figure 1-11 s hows the DIP switch

position for each address number.

Modbusr

Address

DIP Switches

6 7 8

Value=2 Value=4 Value=8

1 Open Open Open

3 Closed Open Open

5 Open Closed Open

7 Closed Closed Open

9 Open Open Closed

11 Closed Open Closed

13 Open Closed Closed

15 Closed Closed Closed

Figure 1-11 Modbusr Device Address

Modbusr is a registered trademark of Schneider Electric.

Loading...

Loading...